In a paper recently published in the Journal of Magnetism and Magnetic Materials, researchers explored the factors required to prepare an efficient ferrofluid (FF) high internal phase emulsion polymer foam (polyHIPE) using polydimethylsiloxane (PDMS) followed by the characterization of its porous structure, magnetic properties, and mechanical properties.

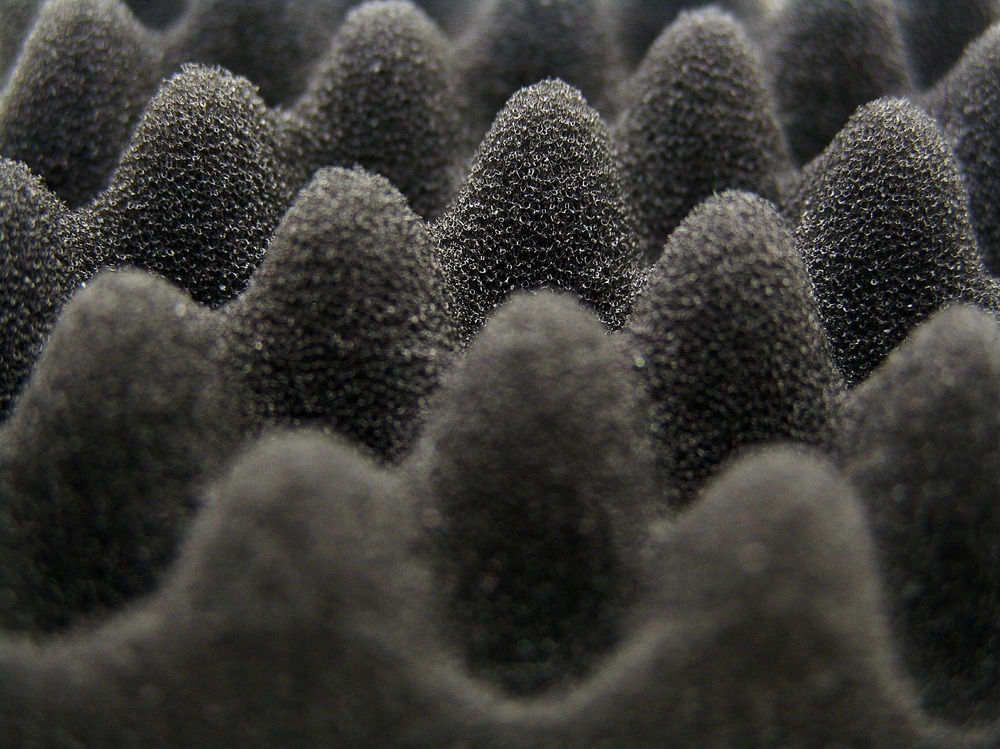

Study: Ferrofluid High Internal Phase Emulsion Polymer Foams for Soft, Magnetic Materials. Image Credit: Yoyochow23/Shutterstock.com

Background

Traditional robotics and electronics rely on conductive, heavy, and stiff materials to perform functions such as information collection, storage, and power transmission. Several ways have been used to create conductive and soft devices. Conductive polymers, which use conjugated, ion, or electron transporting structures across an organic backbone, are a rapidly growing field of study. For widespread applications, conductive polymers must first resolve production challenges along with relatively large moduli and low conductivities.

Magnetic materials make up crucial components of speakers, hard drives, actuators, and magnetic resonance equipment. Deformable magnetic materials should be developed together with capacitive and soft conductive components in order to fabricate self-powered and inductive sensors and electronics.

Furthermore, the increased addition of stiff materials to a softer polymer composite significantly increases the viscosity or bulk modulus, thereby decreasing overall deformability. A study discovered that "cloaking" stiff magnetic particles within a liquid solution inhibited their increase in modulus. However, there has always been a constraint on the quantity of fluid as well as magnetic particles that can be incorporated into a polymer before phase inversion or phase separation. This restricts the material's potential magnetic properties.

About the Study

In this study, the team used a novel approach to prepare polyHIPE with higher loading than was previously achievable. The polyHIPE was prepared with an IKA High Shear Ultra Turrax T25. Using the depth composition mode, digital microscopy was employed to examine the cross-sectional area of the cured ferrofluid-in-PDMS (FF/PDMS) polyHIPE.

Furthermore, the magnetic characteristics of polyHIPE and FF were investigated using a Digital Measurement Systems-Vibrating Sample magnetometer (DMS-VSM). The torsional modulus of the FF/PDMS polyHIPEs was also characterized.

Observations

Since the standard approach of polyHIPE preparation exhibited complete phase separation, a pre-curing stage was introduced to minimize the time allowed for the oil droplets to separate and coalesce. With the precure time set at 40 minutes, Span 80 and silica nanoparticles were added as stabilizers. Lower silica concentrations were insufficient to maintain the mineral oil/PDMS (MO/PDMS) interface, whereas higher silica concentrations produced an under-cured gel-like polyHIPE structure. This emulsion did not exhibit phase separation. Therefore, it was determined that the 30 wt% Span 80 and 5 wt% silica blend was adequate for the stabilization of the MO/PDMS interface. However, the high silica content combined with the extended precure led to a non-moldable/pourable polyHIPE.

Moreover, the vinyl groups were added to enhance crosslinking. A uniform system was then established using 100% vinyl-terminated PDMS. However, it was greasy to the touch, indicating incomplete curing of the system. The final formulation of 5% fumed silica, 30 wt% Span 80, and 60 vol% FF was observed to be homogeneous, easy to pour into a mold, and fully cured after 10 minutes of pre-curing and overall mixing time. This formulation was examined in terms of magnetic and mechanical properties.

Since the material could be handled without leakages, a closed-cell pore system was assumed, which would be ideal for the composite's continuous usage in robotics and soft electronics. Between the FF/PDMS polyHIPE and the FF, there was a notable drop in saturation magnetization (Ms). This was expected, given the decrease in overall magnetic material concentration. Similarly, iron oxide dispersions show a considerable drop in Ms with a reduction in the magnetic material concentration. The FF's magnetic susceptibility was approximately three times that of the FF/PDMS polyHIPE, which was predictable given the polyHIPE's lower magnetic material concentration.

The FF/PDMS polyHIPE showed low magnetic remanence and coercivity and enhanced magnetic saturation. Additionally, a lesser reduction in susceptibility was observed upon FF dispersion when compared to the current core/sheath ferrofluid polymer fibers as well as in-FF polymer dispersions.

Conclusions

To summarize, the researchers produced a novel curable, moldable, and pourable FF/PDMS polyHIPE with 60% FF internal volume fraction. It was determined that material fabrication by high internal phase emulsification could be a potential approach for producing mechanically soft elastomer composites comprising adequate magnetic characteristics. According to the authors, this study indicated a promising avenue for soft components with improved magnetic characteristics. The resultant polyHIPE would have enhanced magnetic characteristics while remaining deformable and soft by increasing the concentration of the internal phase. This can be further enhanced by regulating the dispersed particle and polymer interface interactions, along with enhancing the FF.

More from AZoM: What is the Function of Isotopic Analysis?

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

E. Bury, S. Thiagarajan, N. Lazarus, A. Koh, Ferrofluid High Internal Phase Emulsion Polymer Foams for Soft, Magnetic Materials, Journal of Magnetism and Magnetic Materials (2022), doi: https://doi.org/10.1016/j.jmmm.2022.169921.