A team of Cornell scientists has revealed the complete potential of aluminum nitride, a crucial material for the progress of electronics and photonics, through the creation of a surface-cleaning approach that allows for high-quality production.

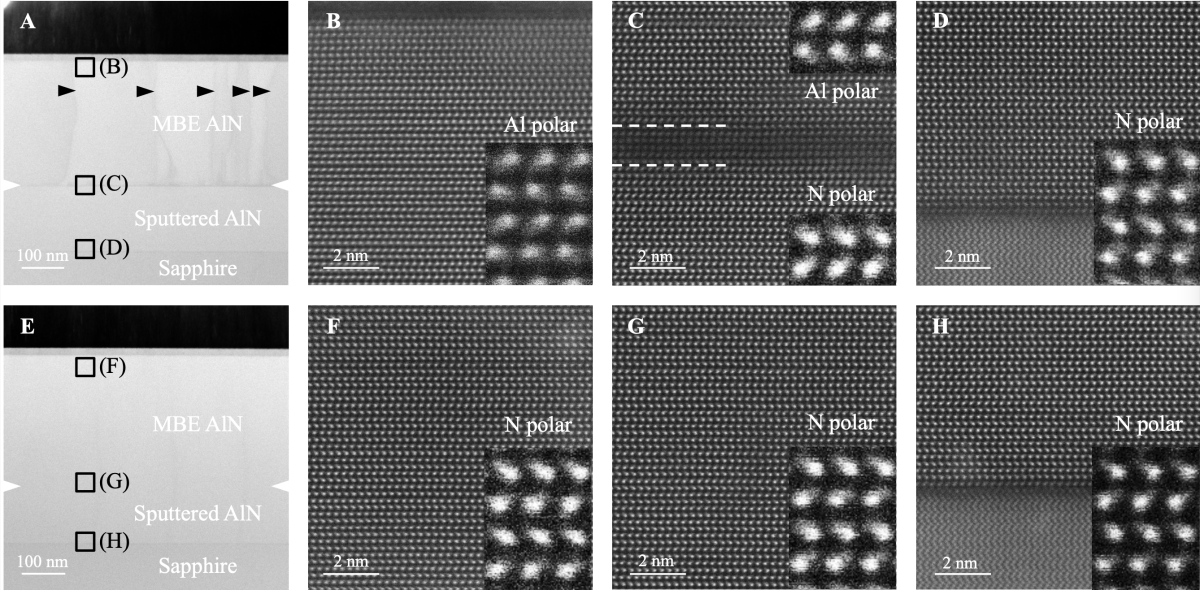

Cross-sectional microscopy images of molecular beam epitaxy-grown aluminum nitride on aluminum nitride templates. The black squares in (A) and (E) mark the regions where the corresponding magnified images (B to D and F to H) are taken. The white notches in (A) and (E) indicate the growth interfaces. The image contrasts in the molecular beam epitaxy layer and at the growth interface in sample A (A) are absent in sample B (E). Image Credit: Jena-Xing Group.

The findings were published on September 9th, 2022, in the journal Science Advances. The principal authors are graduate student Zexuan Zhang and research associate Yongjin Cho. Debdeep Jena and Huili Grace Xing, both professors of materials science and engineering and electrical and computer engineering, are the senior authors.

According to Zhang, aluminum nitride has aroused tremendous research interest in the realm of semiconductor materials because it offers an unrivaled combination of high electrical resistivity and thermal conductivity.

The ceramic substance is utilized as an electrically insulating but thermally conducting barrier in electronic devices, and it has significant promise for use in light-emitting diodes and lasers because of its capacity to function at deep UV frequencies.

The polarity of the material is an important trait that can improve its functionality, and the nitrogen-polar form can accomplish intriguing new performance advantages. Materials scientists, on the other hand, have yet to successfully construct a nitrogen-polar aluminum-nitride crystal on large-area native substrates employing molecular beam epitaxy, a popular growth approach for high-quality heterostructures.

Growing aluminum nitride on native substrates using molecular beam epitaxy has been hampered by difficulties with the removal of native oxides and other chemical impurities on aluminum-nitride wafers, which lead to polarity inversion and defect formation at the growth interface.

Yongjin Cho, Research Associate, Cornell University

To address this issue, the study team created an aluminum-assisted surface cleaning method that cleans the substrates of impurities while preserving the material’s nitrogen polarity. The group was successful in demonstrating nitrogen-polar aluminum nitride epitaxial growth using this technique, and the resulting material had high structural and optical quality and a clean surface shape.

Thermally stable aluminum oxide present on aluminum nitride wafer surface reacts with aluminum and converts to a volatile form, eventually leading to oxide-free wafer surface for epitaxial growth.

Yongjin Cho, Research Associate, Cornell University

Cho adds that the successful demonstration provides proof of concept for nitrogen-polar electrical devices, which are thought to exceed their metal-polar equivalents and have been extensively used in millimeter-wave applications.

The efficiency to generate deep ultra-violet photons is critically dependent on the defect control in aluminum nitride and its alloys. That is why we are excited about the progress made to grow higher quality materials on the aluminum-nitride platform.

Huili Grace Xing, Professor, Materials Science and Engineering, Cornell University

Graduate student Jashan Singhal, senior research associate Vladimir Protasenko, and researchers from Osaka University and Mie University were the co-authors of the study.

The study was supported by the US Department of Energy, Air Force Office of Scientific Research, Cornell Center for Materials Research, the Kavli Institute at Cornell, and the Japan Society for the Promotion of Science.

Journal Reference

Zhang, Z., et al. (2022) Molecular beam homoepitaxy of N-polar AlN: Enabling role of aluminum-assisted surface cleaning. Science Advances. doi.org/10.1126/sciadv.abo6408.