A new paper in the journal NPG Asia Materials has provided a route toward realizing ceramic capacitors for highly efficient devices with self-powering abilities. The work has been conducted by a team from Kumamoto University in Japan and KYOCERA Corporation’s Monozukuri R&D Laboratory.

Study: Utilizing ferrorestorable polarization in energy-storage ceramic capacitors. Image Credit: Picmin/Shutterstock.com

Miniaturized Energy Harvesting and Storage

Designing reliable and efficient miniaturized energy storage devices for use in electronic devices is a key research focus in materials science and electronics. Several applications which can benefit from the rational design of these components include IoT applications, healthcare devices, energy management systems, and safety technologies.

Amongst the miniaturized energy storage devices explored in recent research, capacitors have emerged as suitable candidates and are predicted to provide state-of-the-art solutions for many of the aforementioned applications. However, there are some key challenges associated with the full commercialization of these key system components to achieve advantageous properties such as superior power densities.

Manufacturing standalone systems with long lifespans is one such challenge. Incorporating wireless power technologies or energy harvesters could give applications such as IoT devices semipermanent operation capacities which overcome conventional energy supply constraints.

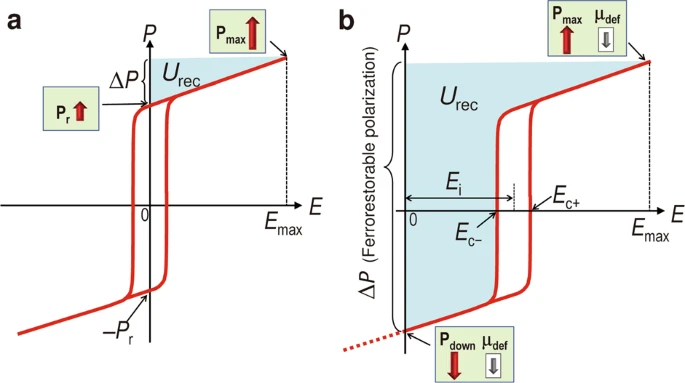

Ferrorestorable polarization. a Typical P-E loop of ferroelectrics (pristine). b Shifted P-E loop with an internal electric field (Ei) caused by the ground-state configuration of μdef || Ps (controlled). The controlled sample has a large Urec as a result of ΔP, which is termed ferrorestorable polarization. The interaction between μdef and Ps stabilizes the downward polarization (Pdown) at zero field, i.e., P0 = Pdown, because the P-E loop shifts to a positive field by the magnitude of Ei. Ei is defined as the average of Ec+ and Ec−, that is, Ei=(Ec++Ec−)/2Ei=(Ec++Ec−)/2, where Ec+ and Ec− are the electric fields at the extreme polarization switching currents in the positive and negative field sweeps, respectively. Image Credit: Matsuo, H et al., Npg Asia Materials

Ceramic Capacitors: A Route Toward Self-Powered Miniaturized Electronics

As with any electronic component, the design of highly efficient and durable miniaturized energy storage devices relies heavily on the selection of suitable materials. In recent research, ceramics have emerged as advanced material candidates for this crucial application due to their long lifetimes and robustness.

Ceramic capacitors represent an advanced solution to the problems of miniaturized electronics research, but in order to be considered commercially viable components, their currently reported energy densities must be significantly improved. To improve this, studies have investigated the incorporation of polar materials such as ferroelectrics, paralectrics, and relaxors.

One solution is to improve the breakdown electric field. However, there are some challenges associated with this, as operations under high yields which utilize the principle of unchanged dielectric permittivity impact the capacitor’s useable lifetime. This therefore negatively affects the commercial viability of ceramic capacitors, and new, more highly efficient strategies must be introduced to overcome this.

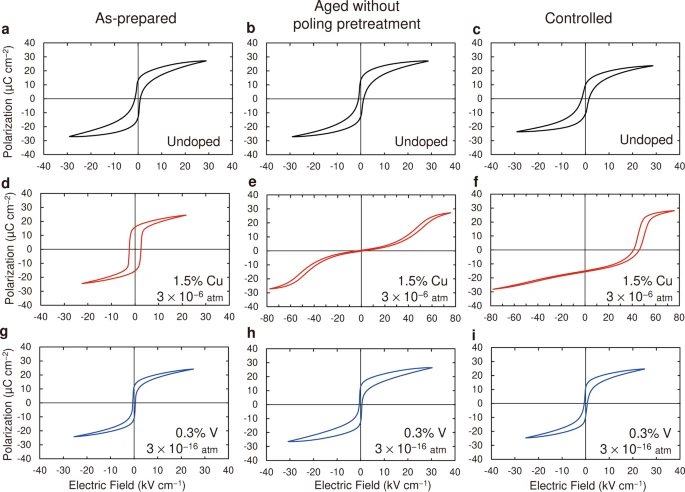

Polarization properties. a–c Undoped samples. d–f, Cu (1.5%)-doped samples at pO2900 °C = 3 × 10−6 atm. g–h V (0.3%)-doped samples at pO2900 °C = 3 × 10−16 atm. a, d, g, As-prepared. b, e, h, Aged without poling pretreatment. c, f, i, Aged with poling pretreatment (controlled). Image Credit: Matsuo, H et al., Npg Asia Materials

The Paper

The new study in the journal Npg Asia Materials has explored the development of new and improved ceramics-based capacitors for energy storage in miniaturized devices. Ferrorestorable polarization engineering, which can significantly enhance the system’s effective permittivity, is reported in the paper. Ferrorestorable polarization possesses benefits such as stabilizing the downward polarization at zero field.

The model material selected in the paper to study electrical property enhancement in this class of advanced capacitors was a ferroelectric BaTiO3 ceramic. DFT calculations were employed to understand the behaviors of the sample materials.

The authors prepared vanadium and copper-doped BaTiO3 powders. BaCO3, TiO2, CuO, and V2O5 powders were combined using ball milling techniques. The prepared ceramic powders were then calcined for five to ten hours at 850-1000 oC. After this calcination step, the powders were then ball-milled again, and disks with a diameter of ten millimeters were prepared using uniaxial pressing.

Disks were isostatically pressed for one hour and sintered for five to ten hours at 1200-1400 oC. The final sintered disks underwent cutting and polishing methods, with the resulting samples having dimensions of 8 x 4 x 0.33 mm. Further annealing was employed to heal any microcracks formed during preparation for 24 hours at 1200 oC. Another annealing step under partial oxygen pressure was employed to control the final Cu valence state and oxygen vacancy concentration.

The annealed samples were then rapidly quenched at room temperature. Poling pretreatment and aging treatments were also used on the samples, with polarization measurements performed both pre- and post-aging for samples.

Measurements of the material’s susceptibility to magnetism alongside ab initio calculations were performed. The susceptibility of the prepared ceramic samples to magnetism was evaluated using a device that measures quantum interference under a 1 T magnetic field and a temperature range of fifty to three hundred Kelvin.

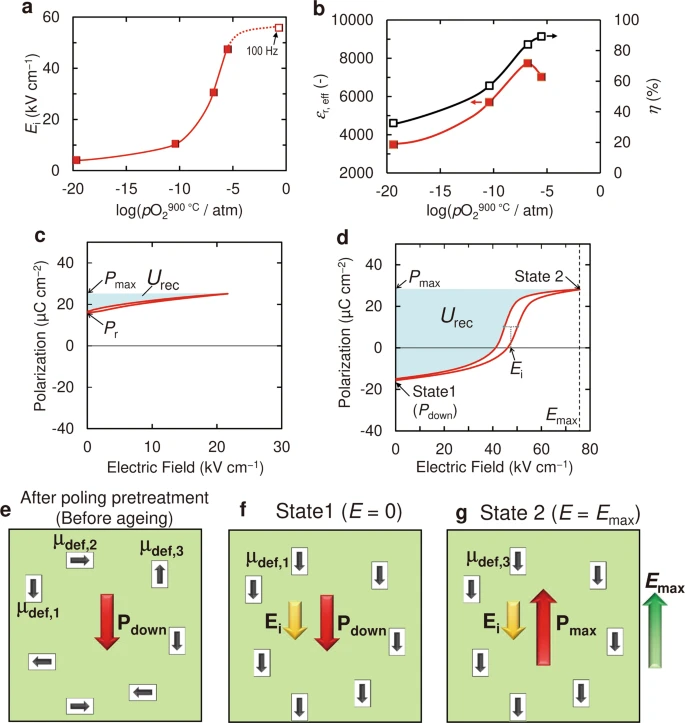

Impact and origin of ferrorestorable polarization. a, b pO2900 °C dependence of Ei and effective relative permittivity (εr, eff) and energy efficiency (η) of the controlled samples with Cu (1.5%). c, d Unipolar polarization curves of the as-prepared and the control samples at pO2900 °C = 3 × 10−6 atm. Schematics of the polarization and μdef configurations of the sample subjected to the poling pretreatment (e) and the controlled sample (f) at zero field. g Configuration of the controlled sample with E = Emax. State 1 of (f) and State 2 of (g) correspond to those in (d). Image Credit: Matsuo, H et al., Npg Asia Materials

Conclusions

The experimental observations and calculations revealed the properties and characteristics of the prepared ceramic samples. The electronic structure of Cu-doped BaTiO3 was unveiled by DFT calculations, with several important observations made such as the stabilization of the system by VO trapping of copper due to a highly attractive interaction.

Provided that there is certain mobility of VO at moderate temperatures and the system is aged, followed by rapid cooling, it can be assumed that there is an association between copper and VO. This forms a CuO5 pyramid with μdef.

Another important observation is that the polarization properties of the prepared ceramic BaTiO3 samples are not influenced by aging, regardless of the use or otherwise of pretreatments. Furthermore, Cu samples display a diverse range of properties that depend on poling pretreatment and aging, as well as Cu valence.

In summary, the paper has demonstrated the successful synthesis of ceramic samples utilizing a ferrorestorable polarization engineering approach and the categorization of their properties and characteristics. This research will serve as a relevant knowledge base for future researchers in the field of ceramic capacitors for miniaturized energy storage applications.

Further Reading

Matsuo, H, Utsunomiya, M & Noguchi, Y (2022) Utilizing ferrorestorable polarization in energy-storage ceramic capacitors Npg Asia Materials 14 (80) [online] nature.com. Available at: https://www.nature.com/articles/s41427-022-00426-z

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.