A team of researchers recently published a paper in the journal Advanced Science that demonstrated the feasibility of using screen-printing multi-walled carbon nanotube (MWCNT)-based conductive ink dispersed by chitin nanocrystals (ChNCs) to fabricate wearable electronic products.

Study: Carbon Nanotube Ink Dispersed by Chitin Nanocrystals for Thermoelectric Converter for Self-Powering Multifunctional Wearable Electronics. Image Credit: raulpd/Shutterstock.com

Background

Conductive inks are used to fabricate multifunctional electronic devices, such as different wearable flexible electronic products, printing sensors, and generators, through the screen-printing process.

The characteristics of wearable flexible electronic products are primarily influenced by the selection of conductive ink. Typically, the conductive ink must possess good adhesion, printability, stability, processability, and conductivity.

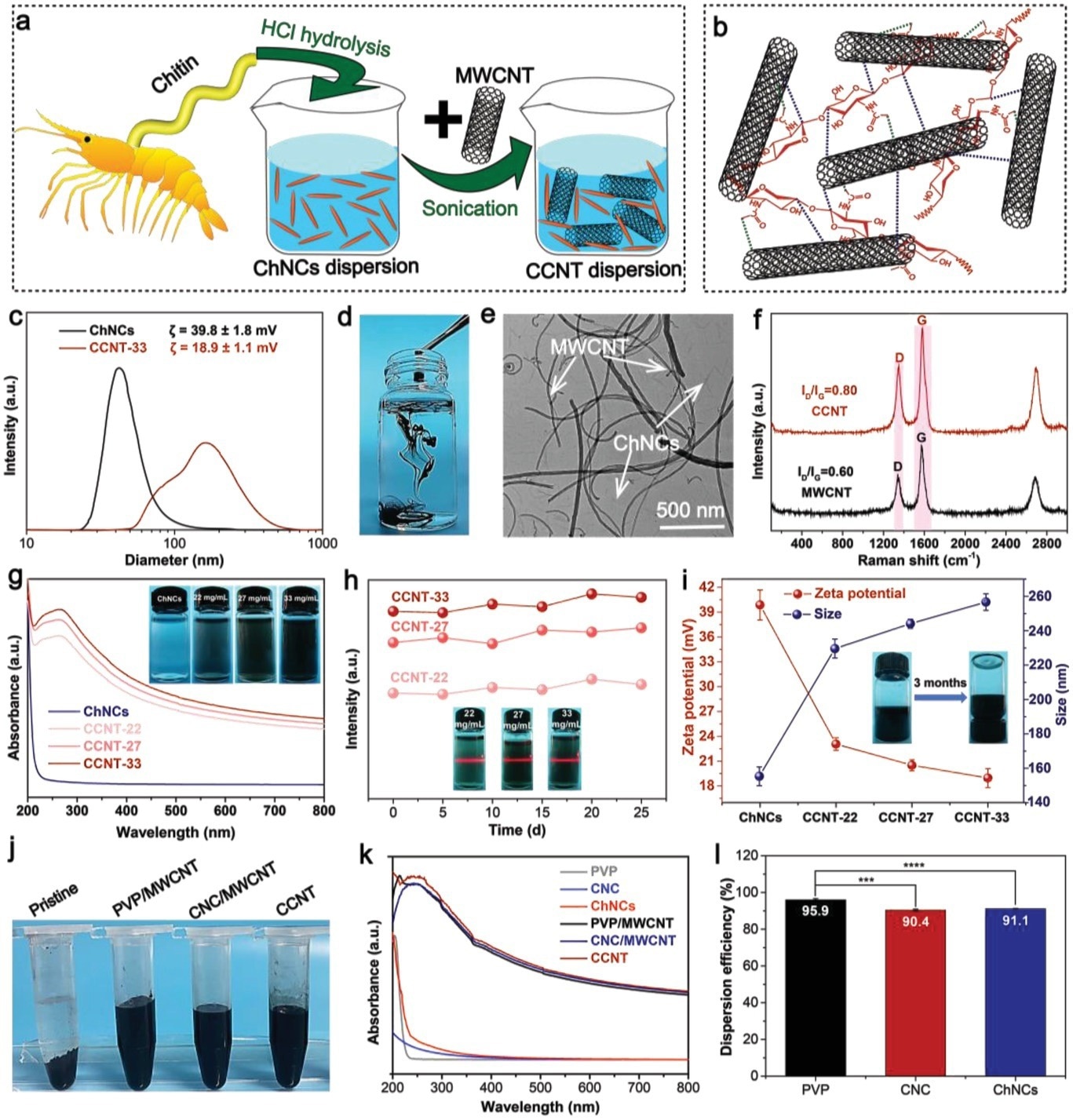

a) Schematic illustration of the formation of CCNT dispersion. b) Noncovalent interactions between MWCNT and ChNCs. c) Zeta potentials and size of ChNCs and CCNT-33. d) Drops of sonicated CCNT in water. e) TheTEM image of CCNT dispersion. f) Raman spectra of MWCNT and CCNT powder. g) UV–vis absorption spectra, h) the maximum UV-vis absorbance (260 nm), and i) zeta potential and size of ChNCs and CCNT dispersions. j) Photograph of MWCNT-water mixtures without dispersant and with 40 mg L−1 of different dispersants. k) UV–vis spectra of PVP, cellulose nanocrystals (CNC), ChNCs, PVP/MWCNT, CNC/MWCNT, and CCNT. l) Dispersion efficiency of PVP, CNC, and ChNCs. (***p = 0.0002, ****p < 0.0001, and n = 3. Data were analyzed by one-way ANOVA and expressed as mean ± SD). Image Credit: Liu, M et al., Advanced Science

The rapid evolution of wearable bioelectronics and electronics and the improvement of environmental protection concepts have increased the focus on water-based conductive “green” inks with good biocompatibility and proper rheology.

In conductive ink, the solid particles primarily include carbon-based materials such as carbon nanotube (CNT) and conductive carbon black and metals in the form of metal nanowires and nanoparticles.

CNT is considered a suitable material for high-quality conductive ink due to its exceptional thermal and electrical characteristics, low density, and high stability. Several studies on conductive inks have been primarily focused on single-walled CNTs (SWCNTs) as they have higher conductivity and uniformity. However, the mass production of conductive ink is easier using MWCNTs as they are more flexible, better controlled in shape, and cheaper.

Although the use of CNTs in conductive inks has several benefits, these nanotubes easily self-aggregate in water due to robust π - π interactions among them, which significantly affects the processability, shelf-life, and uniformity of CNT-based conductive ink.

Surfactants and chemical modification are used most extensively to address the CNT aggregation problem in water. However, these treatments can damage the CNT surface structure and adversely impact the conductivity and biocompatibility of the CNT-based ink.

Several natural biological materials, such as carboxylated nanocellulose and sulfated nanocellulose, can improve the CNT dispersion ability in water through noncovalent interactions, including hydrophobic and/or π - π interactions. Moreover, natural materials possess good biocompatibility and rich content.

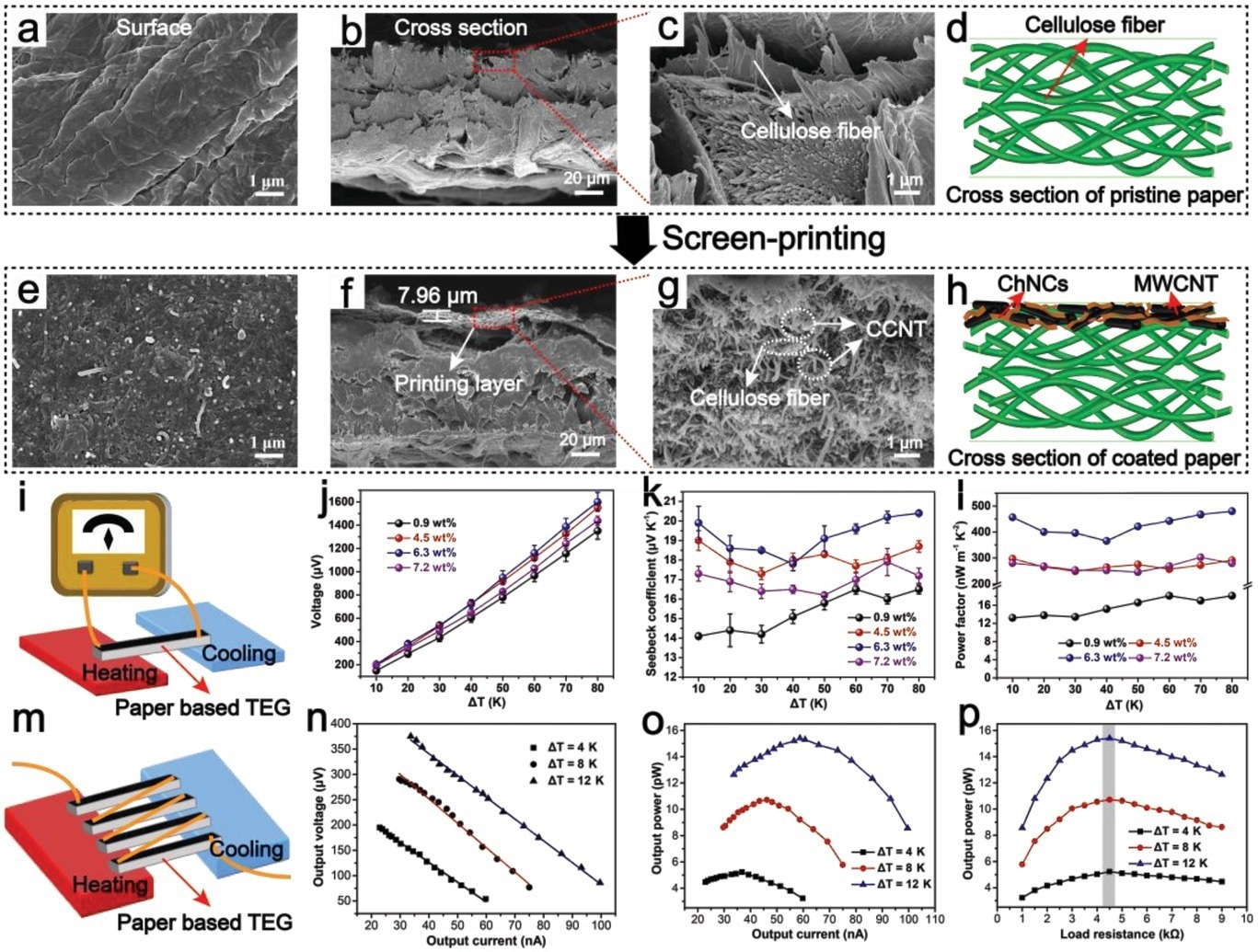

Surface SEM images of a) the pristine paper and e) CCNT coated paper; cross-sectional SEM images of b,c) the pristine paper and f,g) CCNT coated paper. Schematic diagram of d) the pristine paper and h) CCNT coated paper. i) Schematic diagram of an open-circuit voltage measurement device of CCNT coated paper based TEG. j) Voltage, k) Seebeck coefficient, and l) PF of TEG coating prepared by different amounts of CCNT. m) Schematic diagram of a TEG device composed of four CCNT coated paper connected in series. Relationship between n) the output voltage and o) output power versus the current of the TEG under different ΔT. p) Output power of the TEG as a function of load resistance. Image Credit: Liu, M et al., Advanced Science

Thus, natural material-dispersed inks have significant potential in wearable electronic device fabrication. Among the natural biological materials, colloidally stable, nontoxic, highly biodegradable, and positively-charged ChNCs with a one-dimensional (1D) rod-like structure have a high affinity with negatively-charged CNTs.

The ChNC molecular chain can be arranged stably on the hydrophobic CNT surfaces through hydrophobic action due to its amphiphilic nature. Moreover, ChNCs can fix conductive fillers on different substrates, such as glass and paper, as they also act as green adhesives.

Although ChNCs display better biosafety, antibacterial property, and thermal stability compared to other natural dispersants, no study has been performed until now to investigate the potential of ChNCs as a binder and dispersant in CNT-based conductive inks.

Traditional wearable electronic devices are often powered by an external power supply and require frequent battery replacement, leading to potential safety hazards and inconveniences to humans.

Thus, the development of a stable and safe self-powering sensing system is necessary that obtains energy from the human body or the living environment without requiring an external power source.

The Study

In this study, researchers prepared a MWCNT water-based composite ink using ChNCs as an adhesive and dispersant through ultrasonic treatment. Later, they coated the synthesized ink on paper using the screen-printing technology to fabricate a paper-based thermoelectric generator (TEG) to demonstrate the multifunctional applications of MWCNT/ChNCs (CCNT) ink.

Hydrochloric acid hydrolysis was used to extract ChNCs from shrimp shells during ChNC powder preparation. Different amounts of MWCNT were added to ChNC dispersions, and the resultant mixture was ultrasonicated under 70 W power for 60 min to obtain uniform CCNT dispersion.

The obtained CCNT dispersions were designated as CCNT-33, CCNT-27, and CCNT-22 based on the 33, 27, and 22 mg mL−1 MWCNT concentration in the dispersions, respectively.

A polystyrene petri dish was used to cast the CCNT-33 dispersion, which was then dried to prepare the CCNT film. CCNT was coated on cellulose paper, polyethylene terephthalate (PET), and glass using the screen-printing method to determine the feasibility of using ChNCs as adhesive in CNT-based conductive ink.

The CCNT-33 ink concentration was adjusted to 7.2, 6.3, 4.5, and 0.9 wt% by adding deionized water, and the conductive ink was then printed on the cellulose paper surface using a screen-printing plate with a 5 × 15 mm engraved rectangular pattern.

The flexible TEG was fabricated by drying the CCNT-coated papers at 50 oC in an oven, connecting multiple coated papers in series using a copper wire, and packaging the papers with polyimide.

Transmission electron microscopy, Raman spectroscopy, Fourier transform infrared spectroscopy, and ultraviolet-visible spectroscopy were used to characterize the CCNT dispersions.

Researchers also measured the rheological properties, apparent viscosity, viscoelasticity, thermal stability, and contact angle of CCNT dispersions. Additionally, researchers determined the electrical conductivity and biocompatibility of the CCNT-coated paper and evaluated the CCNT-coated paper-based TEG.

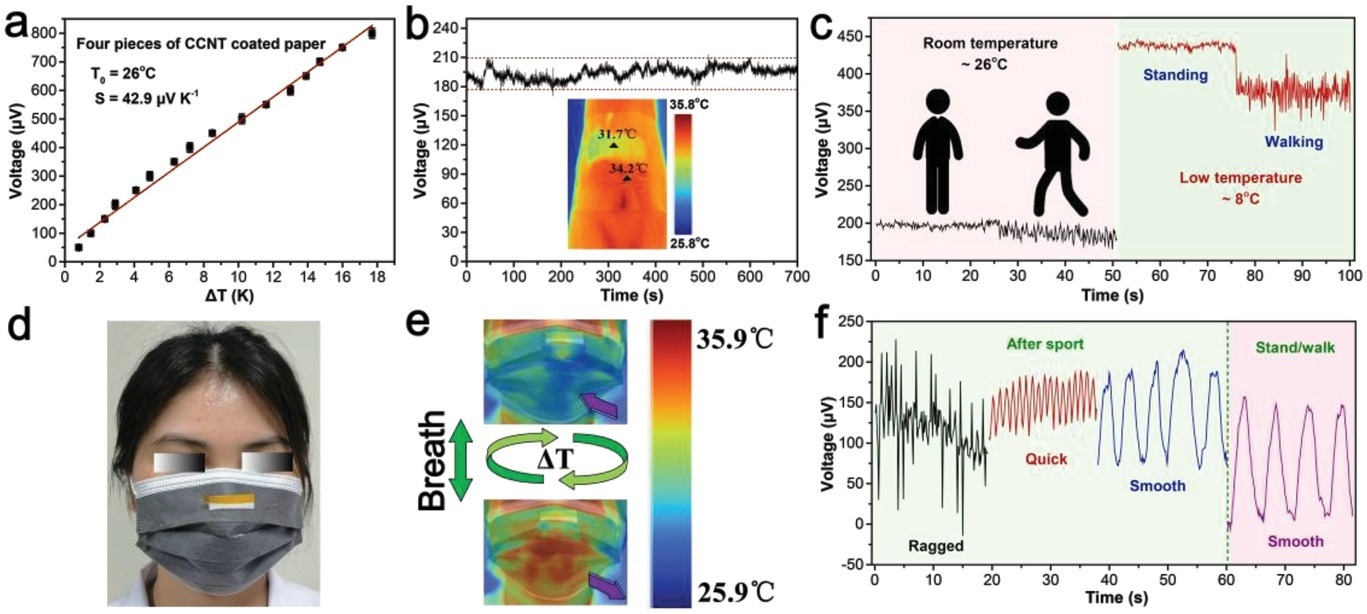

a) Open circuit voltage of thermoelectric generator (TEG) under different temperature difference (n = 3). b) The relation between voltage and time when the TEG was connected to a volunteer's wrist (Inset is an infrared image of a TEG immobilized on the wrist). c) Continuous monitoring of the open circuit voltage of the test subject wearing the TEG while standing or walking at room or low temperature. d) Photo of masks used for respiratory rate detection. e) Infrared image of exhalation and inhalation while wearing a mask. f) At room temperature, wearing a mask was used to detect the voltage of breathing afterdoing sports or standing/walking. Image Credit: Liu, M et al., Advanced Science

Observations

MWCNT water-based composite ink with exceptional uniformity, high viscosity, and stable dispersion was synthesized successfully through ultrasonic treatment using ChNCs as the dispersant. Noncovalent interactions, including hydrophobic interactions, electrostatic attractions, and π - π interactions, were observed between MWCNT and naturally-derived ChNCs.

The CCNT dispersion displayed excellent dispersibility and stability, with 91.1% dispersion efficiency, due to the high colloidal stability of ChNCs. The CCNT dispersion also showed good adaptability and printability to different substrates, such as glass and paper, due to the use of ChNCs as adhesive, indicating the feasibility of using the CCNT dispersion as conductive ink.

Self-supporting films formed from the CCNT dispersion demonstrated a high conductivity of 1150 S m−1 and a good biocompatibility, confirming its safe application. The CCNT-based TEG possessed good flexibility and biosafety. The CCNT ink uniformly adhered to the inner upper layers and surface of the cellulose paper.

CCNT-based TEG effectively converted thermal energy into electrical energy and produced a maximum 0.375 mV output voltage at 12 K temperature difference. The TEG accurately detected and identified temperature and generated a response at a minimum 0.7 K temperature difference.

The self-powered sensor was designed to convert the thermal voltage signal into musical notes. Moreover, the TEG also displayed a good Seebeck effect with 42.9 μV K−1 Seebeck coefficient.

The TEG relative resistance remained stable even after 1000 bending cycles due to the good flexibility of the cellulose paper substrate. The device can be installed directly in a mask or on the volunteer’s arm to detect the respiratory rate and movement of the human body.

Additionally, the strain sensor sensitively monitored human joint movement under self-powering conditions. Thus, the CCNT-based dispersion could be used effectively to prepare paper-based TEG.

Taken together, the findings of this study demonstrated that the eco-friendly ChNC-dispersed MWCNT-based conductive ink can be used effectively in self-powering multifunctional wearable electronics, which can promote the development of green conductive inks. However, more research is required to improve the thermoelectric performance of the CCNT-coated paper.

Further Reading

Liu, M., Luo, B., Lin, X. et al. Carbon Nanotube Ink Dispersed by Chitin Nanocrystals for Thermoelectric Converter for Self-Powering Multifunctional Wearable Electronics. Advanced Science 2022. https://onlinelibrary.wiley.com/doi/10.1002/advs.202204675

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.