Scientists from Hong Kong have developed a soft, bio-inspired heat pipe technology based on squids. Their research has been published in the journal Droplet.

Study: Squid-like soft heat pipe for multiple heat transport. Image Credit: NaturePicsFilms/Shutterstock.com

Heat Transport

Efficient heat transport is essential for a number of key industries, such as power stations, domestic heating supply, and thermal management systems for human use.

Conventional thermal heat pipes are constructed from metals such as copper and steel, meaning that they are rigid structures that cannot deform. Large heat transfer coefficients of boiling and condensation processes give heat pipes a high heat transport capacity. However, due to their rigid construction, they cannot satisfy complex industrial demands due to the diverse locations of heating and cooling surfaces in practical applications.

For example, the human body has a curvaceous surface, and whilst rigid heat transfer pipes have been successfully employed in car seat heating applications, their rigid nature sacrifices some efficiency. This makes soft pipes a more attractive option for several industries.

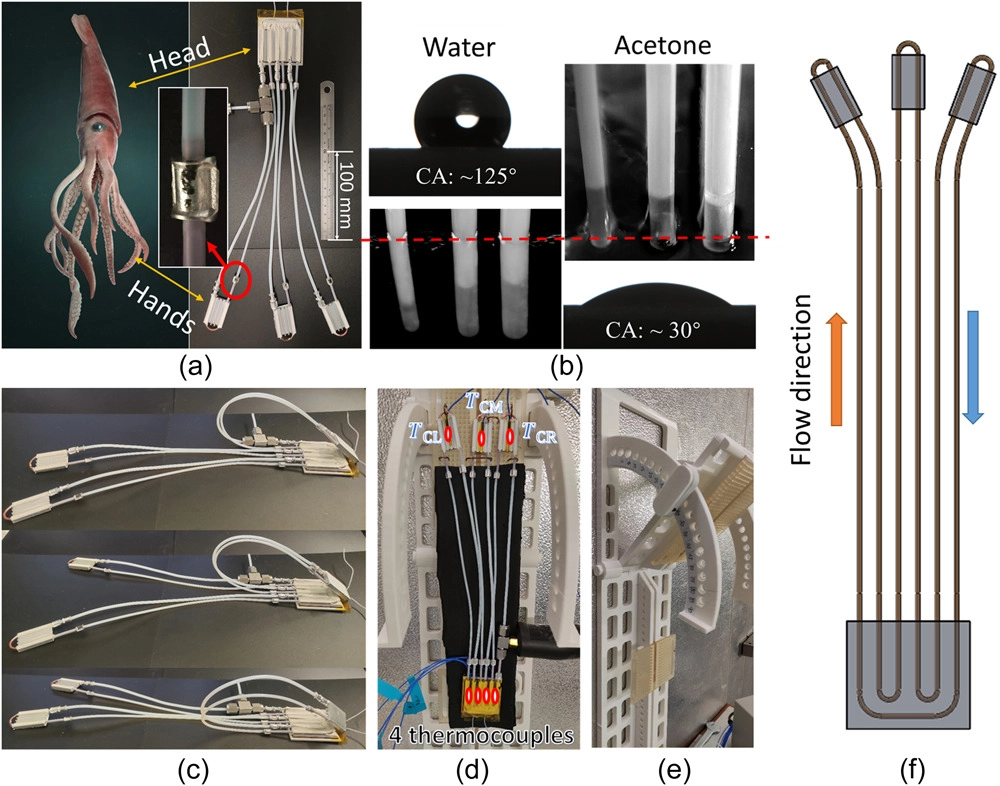

Photos of the (a) squid-like soft heat pipe compared with a squid (the inset photo shows the connection part between the Teflon tube and the copper tube), (b) contact angles (CA) of water and acetone on Teflon and liquid capillary heights in Teflon tubes (the red dashed line indicates the bulk liquid surface), (c) flexibility of different branches of the squid-like soft heat pipe, (d) thermocouple locations of the soft heat pipe, (e) bending shelf, and (f) the heat pipe inner structure. Image Credit: Kang, Z, et al., Droplet

Flexible Heat Transport Pipes

Several commercial applications can be improved by the use of soft pipes, including snow-melting systems, flexible telecommunication devices, wearable technologies, electronic cooling, geothermal power harvesting, waste heat recovery, and thermal management systems for astronauts and workers in extreme environments.

Studies have explored the development of bendable heat transport pipes in recent years, with teams incorporating elements such as flexible bellows and connecting cooling and heating sections using flexible materials such as fluororubber and polyurethane. Other studies have proposed pipes with multiple bendable sections, and research has proved promising, reporting good thermal conductivity.

However, there are some key limitations with currently proposed flexible heat pipe systems. The main drawback to these systems is their limited flexibility due to the small sizes of the flexible sections.

In order to overcome this key limitation, researchers have focused on the development of fully flexible heat pipe systems. One study investigated the construction of pipes with a novel structure composed of casing materials constructed from polyethylene, low-density polyethylene terephthalate, and aluminum. The wicking material is a triple-layered copper woven mesh.

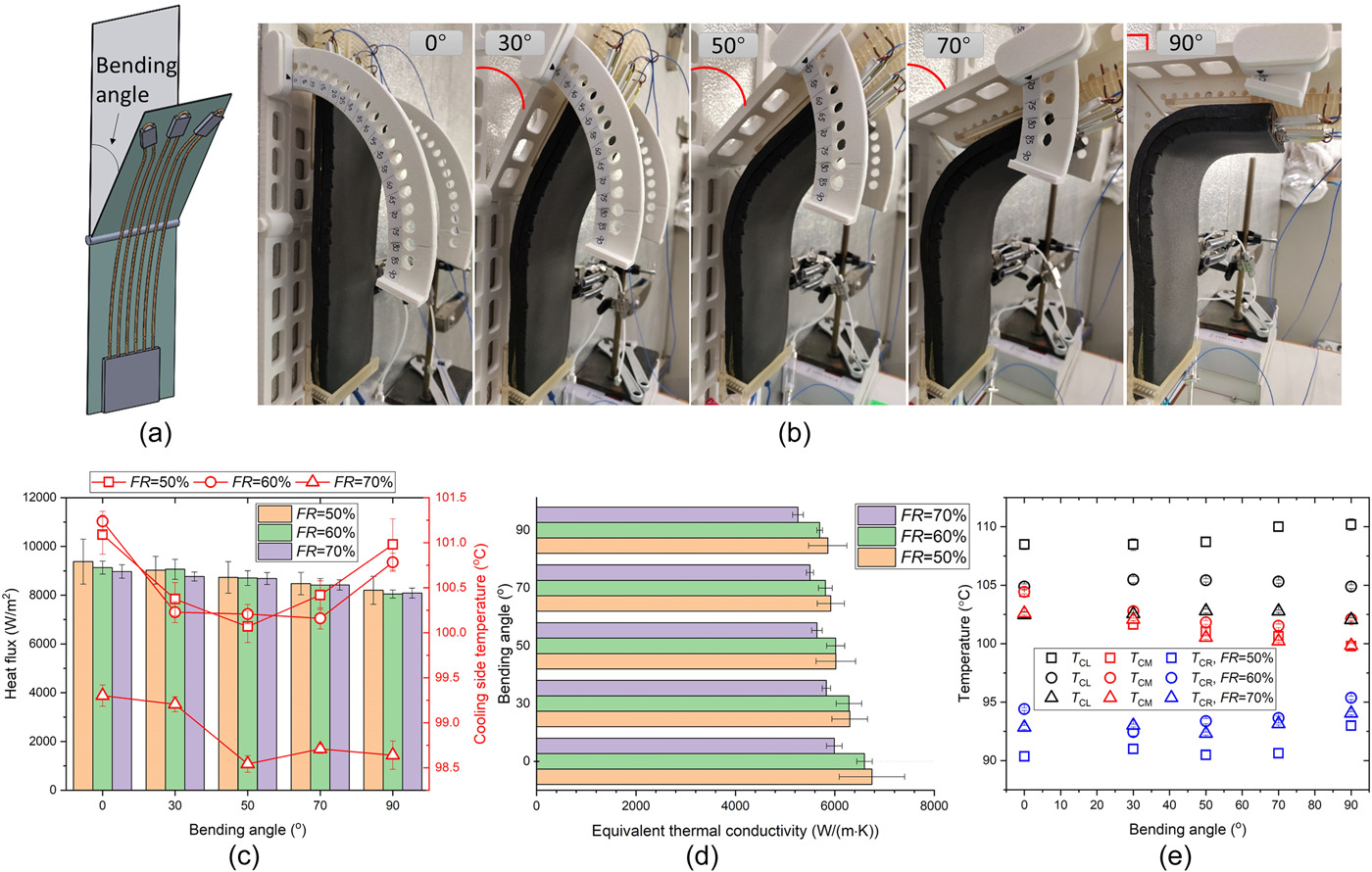

Effect of the bending angle on the heat pipe thermal performance at different filling ratios: (a) Definition of the bending angle, (b) photos of the soft heat pipe at bending angles of 0, 30°, 50°, 70°, and 90°, (c) heat flux of the heating section and average temperature of the cooling pads, (d) equivalent thermal conductivity, and (e) cooling pad temperatures in different branches. Image Credit: Kang, Z, et al., Droplet

Another study used silicon rubber casing and copper woven mesh as wicking materials. However, this flexible heat pipe displayed insufficient thermal conductivity. To improve this, another study proposed using aluminum packing film for the casing material and a nanowire-covered functional copper mesh for the wicking material, which displayed a fourfold improvement in thermal conductivity under some conditions.

A recent development in research is the focus on pulsating heat pipes, which can do away with heat-wicking structures. Pipes with multi-layered laminate composition and pipes with sandwiched structures have been explored in recent papers, as well as branched flexible pulsating heat pipe systems. Whilst early results are promising, some key challenges persist in their design.

The Study

Bio-inspired structures have found key research applications in multiple fields. Taking inspiration from squids, the researchers have developed a heat transfer pipe system with superior flexibility and exceptional heat transfer capacity. The soft heat pipe is constructed of fine tubes made of Teflon with multiple transport branches.

The branched structure of the proposed soft heat transfer pipes delivers heat to multiple locations in the system and provides simultaneous heating and cooling capabilities. The system possesses good scalability, meaning it can be used for both small and large commercial and industrial applications.

A pulsating heat pipe, the squid-inspired system delivers a unidirectional flow of vapor bubbles and liquid slugs, improving significantly on currently reported flexible and soft pipe heat transfer systems.

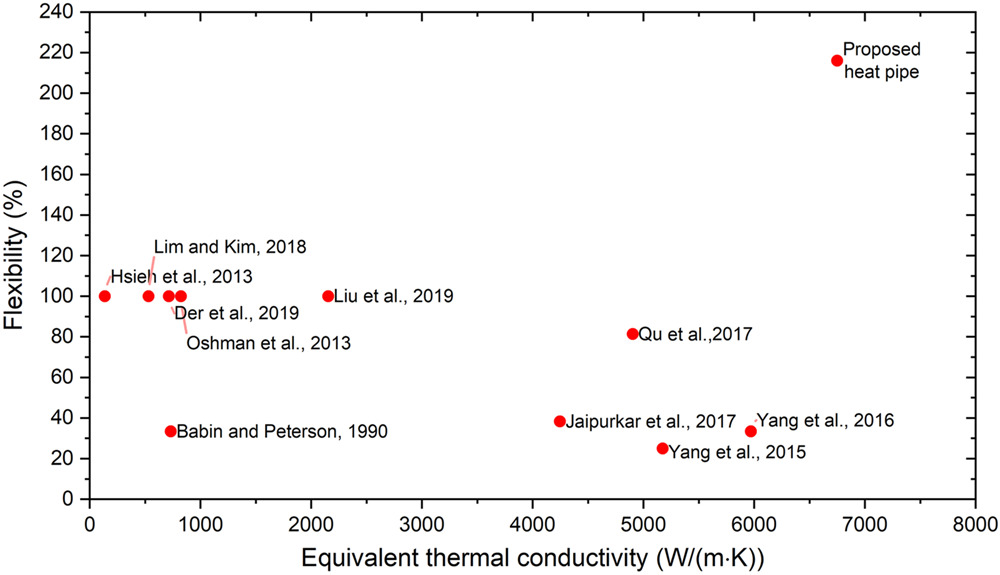

Comparison of the flexibility and equivalent thermal conductivity between the references and the current study. Image Credit: Kang, Z, et al., Droplet

Research Findings and Conclusions

The authors assessed the performance of the soft heat transfer pipes under differing temperature conditions and at different inclinations and bending angles. Results were positive, indicating that the system’s equivalent thermal conductivity could reach almost seventeen times the reported performance of copper.

There was little impact on the squid-inspired system’s thermal conductivity performance in bending tests, with a 90o deformation causing a loss of 10-13%. Inclination angle had a more marked effect on thermal conductivity, with a change from 90-10o causing a loss of 20-25%. Nevertheless, even at 10o, the thermal conductivity performance of the proposed system is five times higher than that of copper.

Additionally, the system can be scaled by increasing the number of branches and overall tube length. The soft pipes can be utilized for multiple heating and cooling applications due to the possibility of branches possessing various cooling pad temperatures. Increasing the heating temperature improves the system’s thermal performance.

Finally, the authors have stated that the promising results contained in their paper demonstrate the suitability of the soft heat pipe system for key applications, such as body thermal management, cooling for soft electronics devices, solar energy systems, and waste heat recovery.

Further Reading

Kang, Z, et al. (2022) Squid-like soft heat pipe for multiple heat transport Droplet [online] onlinelibrary.wiley.com. Available at: https://doi.org/10.1002/dro2.25.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.