Reviewed by Mila PereraOct 25 2022

With the use of a novel “one-pot-and-one-step” synthesis procedure, producing complex polymers with precisely regulated structures has become significantly less complicated.

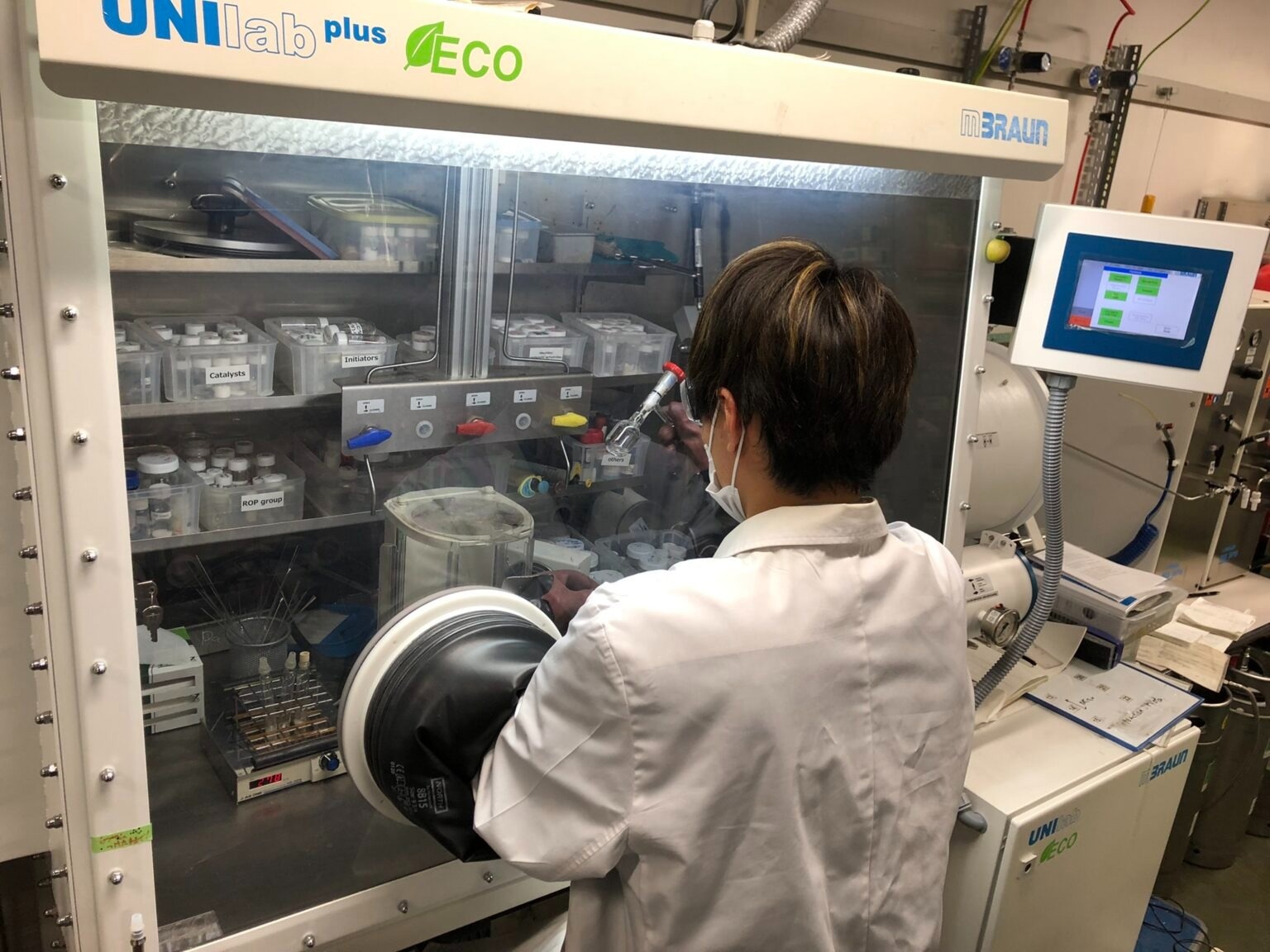

Ryota Suzuki carrying out the one-pot-and-one-step process. Image Credit: Toshifumi Satoh

Ryota Suzuki carrying out the one-pot-and-one-step process. Image Credit: Toshifumi Satoh

Hokkaido University research brings a new level of control producing lengthy and geometrically interlocked polymer molecules from alternating molecular units joined in a controlled sequence.

The method could pave the way for developing a variety of sophisticated materials with applications in various areas, including data storage, drug delivery, microelectronics, and nanolithography.

Synthetic polymers are among the most widely used materials in the modern world, created when individual “monomer” molecules react together to form polymer chains. Polypropylene in packaging, polyesters in clothing, and polyamides in ropes and machinery components are a few examples.

Significant versatility is possible by gaining precise control over the sequence in which different monomer molecules combine to form blocks that link together further. Acquiring control over the formation of these materials, known as block polymers, typically necessitates intricate cycles of chemical processes.

We have managed to control the formation of block polymers in a one-pot-and-one-step process.

Professor Toshifumi Satoh, Division of Applied Chemistry, Hokkaido University

The accomplishment is a demonstration of what is frequently referred to as a one-pot and one-step reaction since it simply involves the addition of the necessary monomers to a single reaction vessel and the use of chemistry to regulate the assembly of the monomers into blocks and eventually into a block polymer.

The monomers in this study are known as cyclic anhydrides, epoxides, and oxetanes. A crucial way to control how they react is using an alkali metal carboxylate, which functions as a catalyst, to switch the polymer-building processes between different reaction forms.

We can control the topology and the two and three-dimensional structure of our polymers, in addition to the basic sequence in which the monomers combine.

Professor Toshifumi Satoh, Professor, Division of Applied Chemistry, Hokkaido University

The scientists illustrated the potential of their technique in one experiment by controlling the combination of four distinct monomers to create diblock tetrapolymers.

The temperatures at which these materials transitioned from solid to viscous and rubbery states, or their glass transition temperatures, could be varied by modifying the exact chemical configurations of the connected blocks. This is just one of the numerous design possibilities offered by manipulating the synthesis reaction.

The process can also produce a wide range of symmetrical polymer molecules, such as globular structures that radiate from a basic core and resemble tree branches.

We are excited to have developed such a controllable polymer production process that could be readily adopted for industrial scale production, as well as being useful for laboratory-level explorations of polymer chemistry.

Professor Toshifumi Satoh, Division of Applied Chemistry, Hokkaido University

The study was funded by the Japan Society for the Promotion of Science Grant-in-Aid for Scientific Research (B) (Grant Number 19H02769); the Ministry of Education, Culture, Sports, Science, and Technology of Japan Grant-in-Aid for Scientific Research on Innovative Areas (Hybrid Catalysis for Enabling Molecular Synthesis on Demand; Grant Numbers 18H04639 and 20H04798); the Frontier Chemistry Center (Hokkaido University); the Photo-excitonic Project (Hokkaido University).

The Creative Research Institution (CRIS, Hokkaido University); the Project of Junior Scientist Promotion at Hokkaido University; Cultivation Plan of the National Natural Science Foundation of China and Social Science Foundation Project (Grant Number 2021PYZ03); and the Science and Technology Research Program of Chongqing Municipal Education Commission (Grant Number KJQN201901109) also supported the research.

Journal Reference

Xia, X., et al. (2022) Multidimensional Control of Repeating Unit/Sequence/Topology for One-Step Synthesis of Block Polymers from Monomer Mixtures. Journal of the American Chemical Society. doi.org/10.1021/jacs.2c06860.