Scientists from the Chinese Academy of Sciences have reported the construction of the largest reported silicon carbide aspheric mirror. Their work has appeared in the journal Light: Science & Applications.

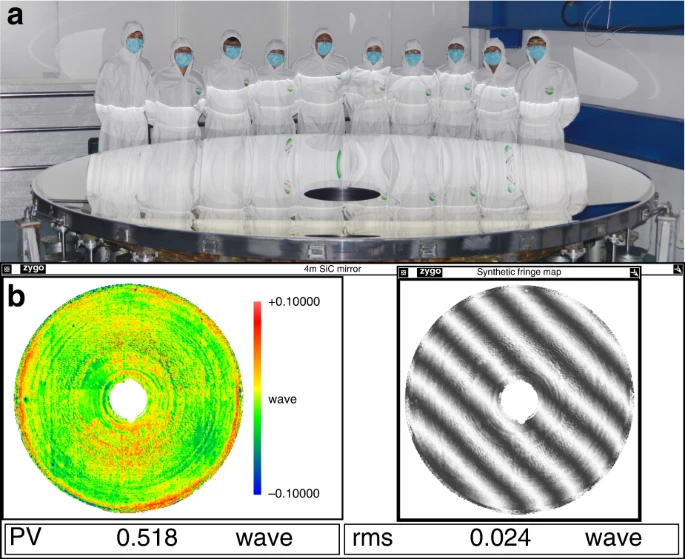

⌀4.03 m SiC aspheric mirror manufacturing results. a Picture of the world’s largest SiC aspheric mirror. b Test result and interferogram of the ⌀4 m SiC aspheric mirror. Study: Challenges and strategies in high-accuracy manufacturing of the world’s largest SiC aspheric mirror. Image Credit: Zhang, X et al., Light: Science & Applications.

What are Aspherical Components?

Aspherical components are essential elements of state-of-the-art optoelectronic instrumentation, such as astronomical telescopes (both ground and space-based), earth observation optical equipment, optical components in deep space probes, and cameras.

Utilizing aspherical components in these devices improves the freedom of their design whilst ensuring that the optical components do not produce additional aberrations. These components reduce the weight and size of optoelectronic systems whilst providing vastly improved imaging quality.

LLC and AR are two key specifications of telescopes, and these have a relationship with the system’s aperture. A larger aperture increases the strength of both AR and LLC. Increasing the telescope’s aperture is a key strategy for improving its performance, with large telescopes in crucial demand.

However, there are some key issues that must be addressed by engineers and researchers which are associated with the large mirrors used in space-based cameras, ground-based observatories, and space telescopes. Stringent requirements govern the materials which can be used in these optical components, as well as the need to control full-spatial shape errors.

For this reason, there is an urgent need for breakthroughs in advanced materials for use in mirrors and the efficient and accurate manufacturing of aspherical mirrors.

Silicon Carbide: A Suitable Material?

Several materials have been assessed for use in high-performance aspherical mirrors for optoelectronic applications in recent years. Silicon carbide has emerged as a suitable candidate due to its high dimensional stability and specific stiffness, two key requirements of aspherical mirror materials.

Due to these advantages, manufacturing a silicon carbide mirror with a large aperture and superior thermal and mechanical properties has become a key focus in the worldwide telescope design community.

Challenges with Silicon Carbide Mirrors

The construction of large aperture silicon carbide mirrors still faces some key challenges, however. Mirror blank preparation, fabrication, testing, cladding, and coating are primary issues. Specific challenges in these areas include the structure’s homogeneity, the fabrication process’s efficiency and accuracy, test procedure precision and fidelity, and air turbulence errors.

Currently, CVD processes are suitable for the reduction of silicon carbide’s surface defects. However, substrates must be heated to extreme temperatures (~1000 oC), and irreversible shape deformation can be induced by large thermal shock. Furthermore, cladding processes carry a significant risk of the mirror cracking.

Complex chemical reactions and phase changes occur during blank preparation, and current technologies cannot satisfactorily create mirrors over ⌀1.5 m. There is no commercially available polishing equipment larger than ⌀2.5 m. Overcoming these technical limitations is key to manufacturing larger aspherical silicon carbide mirrors.

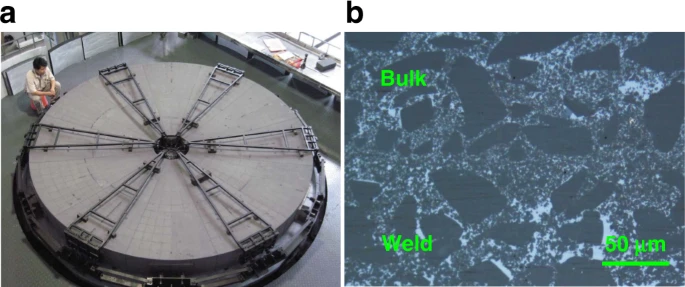

Parts joining and sintering results of ⌀4.03 m SiC blank. a Green body parts joining, b the microstructure photo after sintering. Image Credit: Zhang, X et al., Light: Science & Applications.

The Study

The new paper in Light: Science & Applications is the culmination of two decades of research by scientists from the Chinese Academy of Science.

An innovative processing chain was developed by the team. A purpose-built MRF polishing machine was developed, with a significantly better polishing range than currently reported technologies, at ⌀4.5 m. The processing chain overcomes the problem with low efficiency faced by conventional fabrication methods.

The processing chain and improved technology developed by the authors produced the largest reported silicon carbide aspheric mirror, at ⌀4.03 m. A lightweight, complex green body, silicon carbide binder, and joining process were developed, which allowed silicon carbide segments to be stitched into a monolithic blank. Several novel material preparation techniques were developed by the authors.

A 30% increase in error convergence rate was achieved, making it possible to realize full-spatial frequency error control. The mirror possesses a high shape accuracy of 15.2 nm RMS. A low-temperature manufacturing process was achieved, which causes extremely low deformation of under 5% during cladding processes, with the mirror’s surface quality being extremely high.

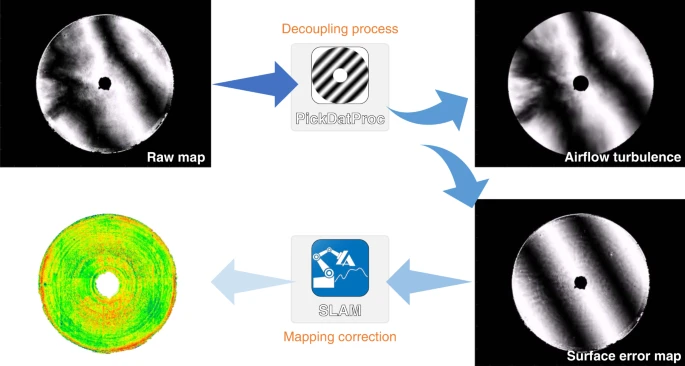

Subtracting the air turbulence induced error during CGH null test. The decoupling algorithm cancels out the effect of air turbulence on large mirror interferometric null test mostly. Image Credit: Zhang, X et al., Light: Science & Applications.

Additionally, the research team has developed a high-precision measurement technique. This is a data fusion technique that seamlessly combines test data from numerous sources. Several novel models and methods were introduced in the paper to improve the high-accuracy testing of the large silicon carbide aspherical mirror developed by the team.

The mirror was delivered for testing in 2019, with satisfactory practical on-site results reported. By manufacturing the largest currently reported silicon carbide aspheric mirror, the team has provided engineers with a powerful new optical tool that will improve the design of telescopes and earth observation cameras in the coming decades.

Further Reading

Zhang, X et al. (2022) Challenges and strategies in high-accuracy manufacturing of the world’s largest SiC aspheric mirror Light: Science & Applications 11, Article no. 310 [online] nature.com. Available at: https://doi.org/10.1038/s41377-022-00994-3

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.