By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Nov 1 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Nov 1 2022In an article recently published in the open-access journal Scientific Reports, researchers discussed a non-destructive method for evaluating the quality of polymer-metal laminates utilizing digital holographic vibrometry and Lamb waves.

Study: A non-destructive technique using digital holographic vibrometry and Lamb waves for quality determination of polymer-metal laminates. Image Credit: Joshua Sanderson Media/Shutterstock.com

Background

Polymer-metal laminates have become more and more common in recent years. Automobile manufacturers are increasingly attempting to lighten their products to increase operational efficiency and lower production costs. The materials for the two partners of the laminate should be chosen based on certain characteristics.

These days, assembly of the two components is accomplished directly during processing without requiring any further stages, using standard techniques like injection molding with metal inserts. However, the metal-polymer joints' hurried production cycles could result in connection flaws.

Although the production processes for polymer-metal laminates are becoming more common, a significant worry remains the vulnerability to the development of concealed or hardly noticeable flaws. While internal faults in such materials, the existence of which may have a substantial impact on the strength of the finished product, are challenging to detect, surface defects in such materials can be very simply identified. Non-destructive testing (NDT) is a helpful technique for examining individual parts for any potential hidden flaws. For large objects and high stimulation frequencies, conventional and well-known non-destructive testing techniques utilizing Lamb waves are applied.

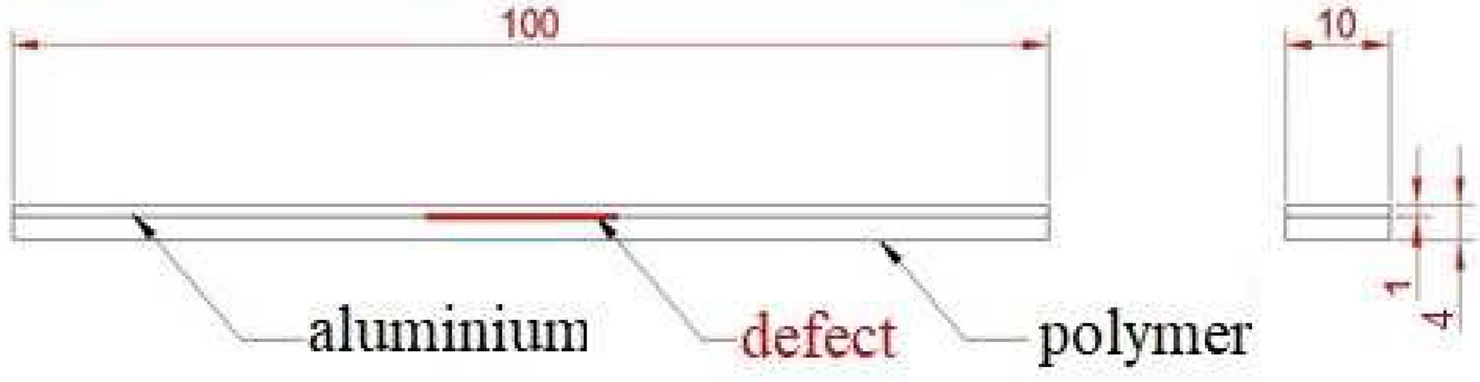

Sideview of a sample with a defect indicated; sizes are in mm. Image Credit: Nowak-Grzebyta, J et al., Scientific Reports

About the Study

In this study, the authors employed a non-destructive technique called digital holographic vibrometry (DHV) to find debonding spots in laminates constructed of aluminum and polymer. The amplitude and phase patterns of the sample's vibration were concurrently recorded for the metal and polymer side of the laminate at low frequencies of up to 30 kHz using A0 Lamb waves. These patterns were used to locate the debonding spots in laminates. The frequency range for which regular Lamb waves were seen, the amplitudes of Lamb waves, and the frequency-dependent Lamb wave propagation velocities were all researched concerning the transmission qualities at low frequencies.

The team demonstrated that when a laminate flaw manifests itself, these attributes were also altered. It was possible to determine if a sample was damaged based on the behavior of the Lamb waves even when the problem was not localized. The methodology was expanded, and the anti-symmetric A0 Lamb waves at various vibration frequencies in samples of laminated aluminum made from three different polymers were observed and their behavior was used to look for hidden flaws. For high frequencies of 100 kHz and above, lamb wave propagation in an isotropic medium was well-defined. For laminates and a relatively low-frequency range of up to 30kHz, this was not the case.

The researchers concentrated on the impact of the flaw on laminates in the low-frequency range for vibrations that happen in daily life, for example, in frequently used gadgets like ultrasonic animal repellents or washing machines, as well as in public spaces like train stations or libraries. Digital holographic vibrometry (DHV) was employed to track the simultaneous Lamb wave propagation on the laminate's metal and polymer sides. In particular for laminates, it was highly helpful to observe both sides. In this manner, the effectiveness of the bonding of laminates formed from polymer and aluminum alloy mixes was evaluated.

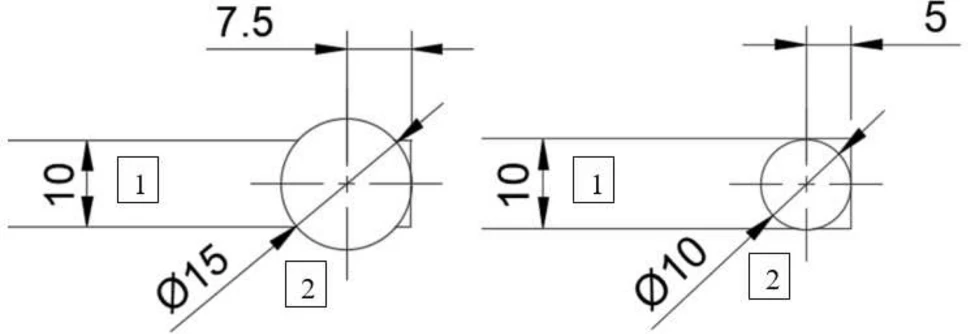

Botton view of a sample with position of both types of piezo trandsucers used: 1: sample, 2: piezo transducer; left: KingState KPE-827, right: PI P-010.00P; sizes are in mm. Image Credit: Nowak-Grzebyta, J et al., Scientific Reports

Observations

The Lamb-wave Frequency Observation Range (LFOR) for which a laminate flaw could be seen was dependent more on the magnitude of the defect than the type of polymer employed. The Lamb-wave propagation in the polymer followed in the metal for all flawless aluminum-polymer laminates. This suggested strong adhesion between the two layers and demonstrated the viability of using any of the polymers examined to create a robust laminate. The proposed setup necessitated access to both sides of the sample since its metal and polymer surfaces were concurrently observed. There were various ways that a bonding fault could show itself. In every instance, the flaw reduced the LFOR.

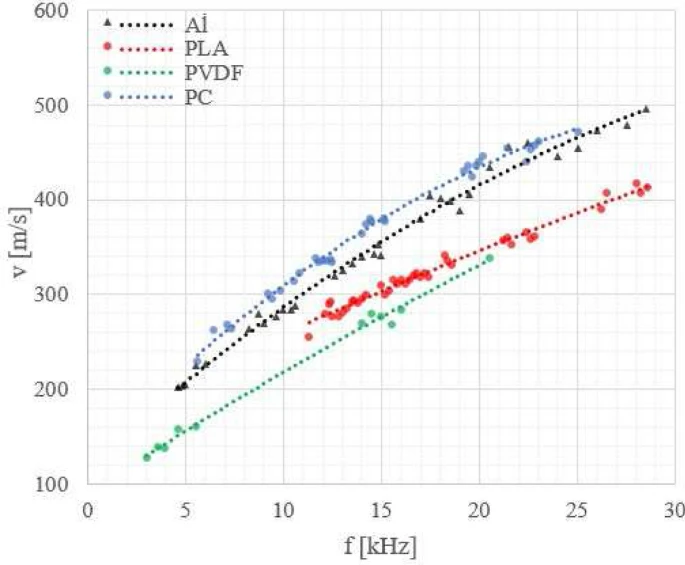

The anti-symmetric A0 Lamb wave velocity vs frequency curves was also dramatically altered. At frequencies greater than 10 kHz, the differences between the curves for the metal and the semi-crystalline polymers were apparent. The polymer portion of the Polyvinylidene fluoride (PVDF) Al D laminate with a defect had a Lamb wave velocity that was roughly 40% lower at a frequency of 15 kHz than the aluminum layer. In the case of semi-crystalline polymers, a laminate flaw widened the gap between the vibration amplitudes of the metal and the polymer.

This discrepancy increased from 40–50% for PVDF Al to 60–70% for PVDF Al D, especially for PVDF, which exhibited the least vibration transmission among the investigated materials. However, even for laminates having a flaw, there was little difference in the vibration amplitudes for amorphous PC Al. Therefore, in the case of laminates with polymers that had good vibration transmission in the test range of low frequencies, the amplitude criterion was not useful.

Comparison of the Lamb wave phase velocities for pure polymer and aluminum samples. Image Credit: Nowak-Grzebyta, J et al., Scientific Reports

Conclusions

In conclusion, this study used two semi-crystalline polymers and one amorphous polymer for the development of laminates.

The authors mentioned that the test samples tested using the proposed technology had appropriate dimensions for additional strength tests. This was helpful for standard component testing in a lab setting as well as in a setting of industrial production.

The team emphasized that the NDT approach described in this study needs a short amount of time to evaluate how well two laminate materials connect. They stressed that it is a helpful extension of the typical laminate tests that can also be done on a manufacturing line to employ DHV to detect Lamb waves.

References

Nowak-Grzebyta, J., Stachowska, E., Meijer, F., et al. (2022) A non-destructive technique using digital holographic vibrometry and Lamb waves for quality determination of polymer-metal laminates. Scientific Reports, 12, p. 18041. https://www.nature.com/articles/s41598-022-22853-2

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.