Reviewed by Alex SmithNov 8 2022

A new study performed by researchers from institutions including Stanford has analyzed large-scale and high-quality III-nitride membranes via microcavity-assisted crack propagation by engineering tensile-stressed Ni layers.

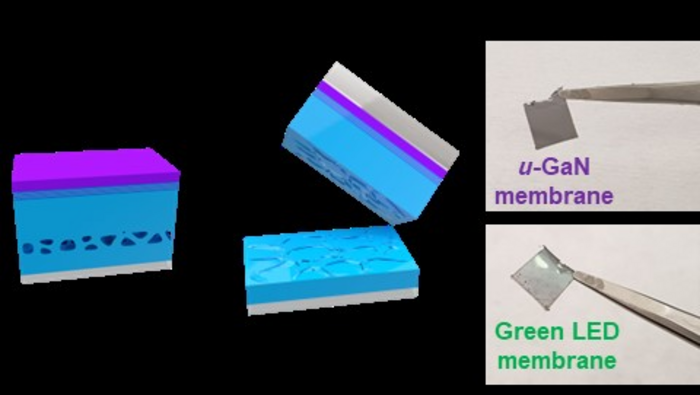

Representative schematic illustration and digital camera images for microcavity-assisted crack propagation and its corresponding undoped-GaN and green LED membranes, respectively. Image Credit: OEA.

The study’s primary aim was to come up with an unparalleled exfoliation method of large-scale and high-quality III-nitride alloys for practical usage in the semiconductor industry. As a whole, a micrometer-thick epitaxial layer for InGaN-based light-emitting diodes (LEDs) are grown on over 100-μm thick sapphire substrates at high temperature (> 1000 °C).

A significant point is that the unavoidable use of thick sapphire substrates has resulted in a lot of flaws like low thermal conductivity, insulative properties, inflexibility, etc. Hence, the LED thin layers grown on the substrates resulted in several difficulties in developing device applications, particularly micro-LED displays.

Even though these shortcomings could be solved by eliminating the substrates, it is difficult as a result of its powerful interfacial fracture toughness along with mixed covalent-ionic bonds. The study performed by the researchers has been devoted to eliminating the substrates at a large scale while retaining the quality of the film for the fabrication of the III-nitride membranes.

In short, intermediate microcavity layers have been initiated to ease the interfacial fracture toughness, and the residual tensile-stressed Ni layers were fabricated to obtain an adequate energy release rate to handily flake the GaN-based layers from the interfaces.

Depending on this mechanical lift-off method, researchers illustrated large-scale undoped-GaN and green LED membranes and confirmed the quality by producing optoelectronic devices, like vertical-type green LEDs and ultraviolet (UV) photodetectors following the large-scale exfoliation.

The article’s authors initiate microcavity-assisted crack propagation to achieve large-scale and high-quality III-nitride membranes. Nanoporous structures have been invented to be utilized as a template to increase high-quality GaN-based layers like green LEDs and undoped-GaN.

At the time of the layers’ high-temperature overgrowth, the nanoporous structures were converted into micro-size cavity structures. The primary role of the micro-size cavity structures is to ease the original interfacial toughness of GaN by decreasing surface area.

Image Credit: sdecoret/Shutterstock.com

The decreased interfacial toughness is known as the efficient interfacial toughness, and it could be adjusted by the depth of nanoporous structures and the control of the surface porosity. Depending on the overgrown target layers (undoped-GaN and green LEDs) with the efficient interfacial toughness, it is said that employing tensile-stressed Ni layers, known as a Ni stressor, offers an adequate energy release rate.

It was possible for the target layers to be exfoliated easily at the interfaces of microcavity structures by corresponding to the energy release rate achieved from the Ni stressors. This was deposited by electroplating to the efficient interfacial toughness.

As soon as the large-scale exfoliation is completed, the quality of the undoped-GaN membrane was confirmed by quantifying rocking curves via X-Ray diffraction. Furthermore, scientists illustrated greed LEDs and vertical-type UV photodetectors that were manufactured by the exfoliated membranes.

The devices displayed moderate optical and electrical performances, which could also show that the thin films’ quality has been preserved subsequently after the large-scale exfoliation.

Journal Reference:

Min, J-H., et al. (2022) Large-scale and high-quality III-nitride membranes through microcavity-assisted crack propagation by engineering tensile-stressed Ni layers. Opto-Electronic Science. doi.org/10.29026/oes.2022.220016.