A research team has created a bulk copper-based alloy that, to date, has the greatest tensile elastic strain at room temperature.

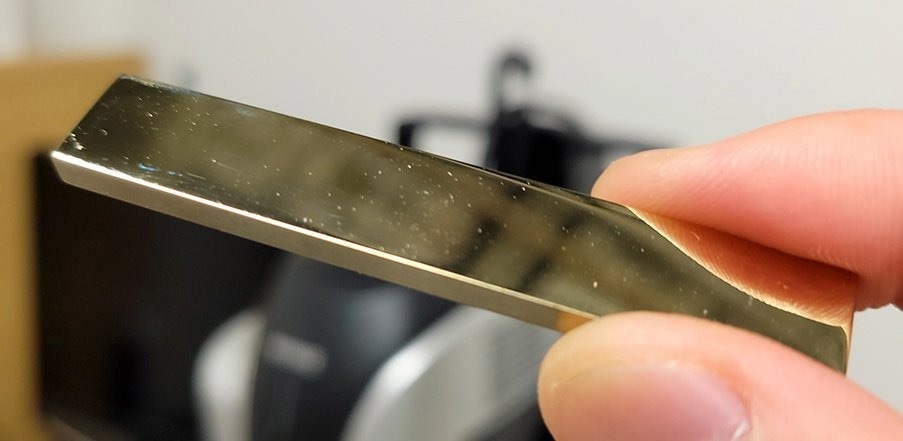

Image Credit: Tohoku University

Metals are elastic, meaning they can return to their original shape even after being put under a certain amount of stress. Large elastic deformation materials are in high demand because they offer greater flexibility in everyday sporting goods and medical equipment.

The majority of metals and alloys can theoretically withstand a strain value of 10%, but only when the metals are shrunk to micro or nano scales. The elastic strain of these metals falls to less than 1% when they are in their bulk form, which is how they are in the majority of real-world engineering applications. For instance, stainless steel has an elastic strain of <0.2%.

The group’s bulk copper-based alloy showed a tensile elastic strain of >4.3% at room temperature under the direction of Sheng Xu, a specially appointed assistant professor at Tohoku University’s Graduate School of Engineering. This was made possible by the reversible lattice strain of the BCC single phase.

Due to the material’s elastic softening behavior, the relationship between tensile stress and strain was nonlinear, deviating from conventional Hooke’s law behavior.

As a generalization of the elasticity theory, Hooke's law states that an object’s elasticity is inversely correlated with the amount of stress it is subjected to. Low Young’s modulus, or the measurement of how easily a material can stretch or deform, and high strength are required to obtain a large elastic strain. The trade-off between these properties exists in conventional metallic materials, though.

The new material nevertheless showed a singularly low Young’s modulus of <25GPa and a high Poisson's ratio of 0.47. In other words, the substance is remarkably strong and highly elastic, even when subjected to minor stresses.

Additionally, a straightforward procedure that enables mass production, cyclic heat treatment, is needed to prepare the alloy’s bulk single crystals.

Our bulk alloy can be used as spring materials with high recoverability, and they could also be applied to devices that employ strain-mediated sensors, such as stretchable electronics. The new alloy’s low Young’s modulus resembles human bones and therefore has the potential for use in medical applications.

Sheng Xu, Assistant Professor, Department of Materials Science, Graduate School of Engineering, Tohoku University

On September 27th, 2022, Nature Communications published a summary of the study.

The research team plans to test the alloy’s functional fatigue under large elastic deformations in the future, which is crucial for its practical applications. Additionally, they are working with related industries to investigate additional uses for the alloy.

Journal Reference:

Xu, S., et al. (2022). Non-Hookean large elastic deformation in bulk crystalline metals. Nature Communications. doi:10.1038/s41467-022-32930-9