3D-Micromac AG, the industry leader in laser micromachining and roll-to-roll laser systems for the semiconductor, photovoltaic, glass and display markets, today announced that it has entered into a joint-development partnership (JDP) with SCHOTT, a leading international technology group and inventor of specialty glass, to improve the processing performance of SCHOTT RealView® high refractive index wafers used in manufacturing waveguides for next-generation augmented reality (AR) and mixed reality (MR) headsets.

SCHOTT RealView® high refractive index wafers help smart glasses create a stunningly realistic hands-free experience. Image source: SCHOTT.

SCHOTT RealView® high refractive index wafers help smart glasses create a stunningly realistic hands-free experience. Image source: SCHOTT.

The JDP builds on an existing multi-year relationship between the two companies, and will focus on two key areas: the development of a dedicated laser cutting process for SCHOTT RealView® glass wafers that increases glass edge strength for improved production yields; and the development of a high-volume-manufacturing-capable laser micromachining tool that can achieve a throughput of nearly 600 AR eyepieces per hour, or approximately five million AR eyepieces annually in 24/7 production. While the laser micromachining process and system will be optimized for SCHOTT RealView®, 3D-Micromac will ensure its compatibility with other materials and sell the system to any end customer for any glass product.

According to Matthias Jotz, Head of Product Management for Augmented Reality at SCHOTT, “High refractive index glass is a key component for achieving optimum field of view and first-class image quality for AR headsets, providing the ultimate user experience. To scale up manufacturing on our patented SCHOTT RealView® high refractive index glass products, it is critical that we partner with the right equipment suppliers that can support our manufacturing goals with enabling process solutions. SCHOTT has worked with 3D-Micromac over many years, and their expertise in laser micromachining make them an ideal partner for developing a dedicated laser cutting technology for our augmented reality products.”

“3D-Micromac has been offering innovative laser machining solutions for the AR device market for several years, and this strategic partnership with SCHOTT, one of the foremost leaders in specialty glass, will further position us as a leading solutions provider for this high-growth-potential market,” stated Uwe Wagner, CEO of 3D-Micromac. “We believe that SCHOTT’s strong know-how and expertise in glass processing and material science, coupled with our leadership in laser micromachining, will enable us to develop new process solutions that can improve the bending strength of high refractive index glass to optimize yields while reducing production costs.”

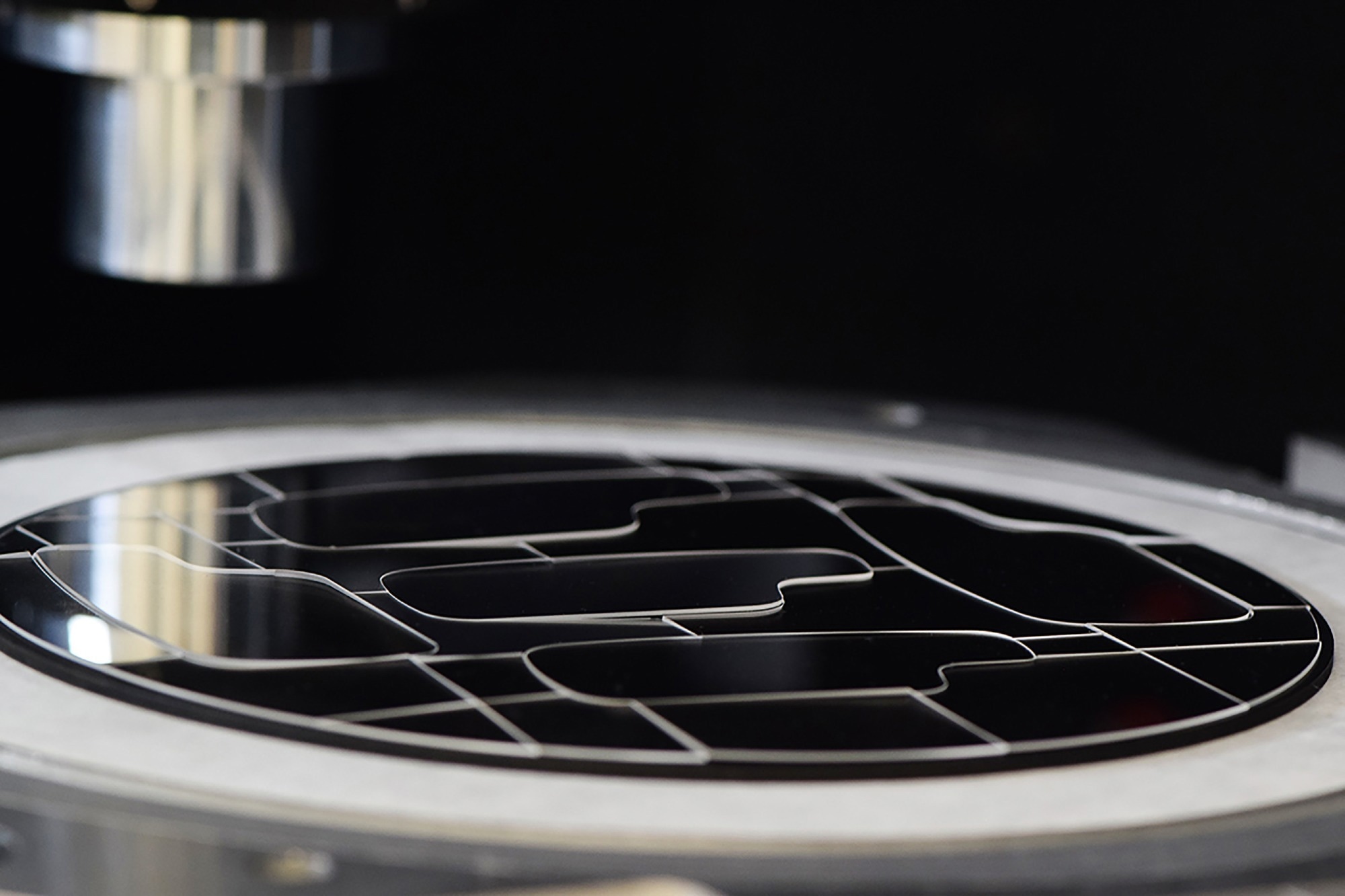

Layout of SCHOTT RealView® eyepieces on a high refractive index wafer following laser cutting with a 3D-Micromac laser micromachining system. Image source: 3D-Micromac.