Bifacial thin film solar cells constructed from copper indium gallium diselenide, or CIGS, may gather solar energy from both their front and back sides, possibly yielding more solar energy than traditional equivalents. However, their development has resulted in very moderate energy conversion efficiency.

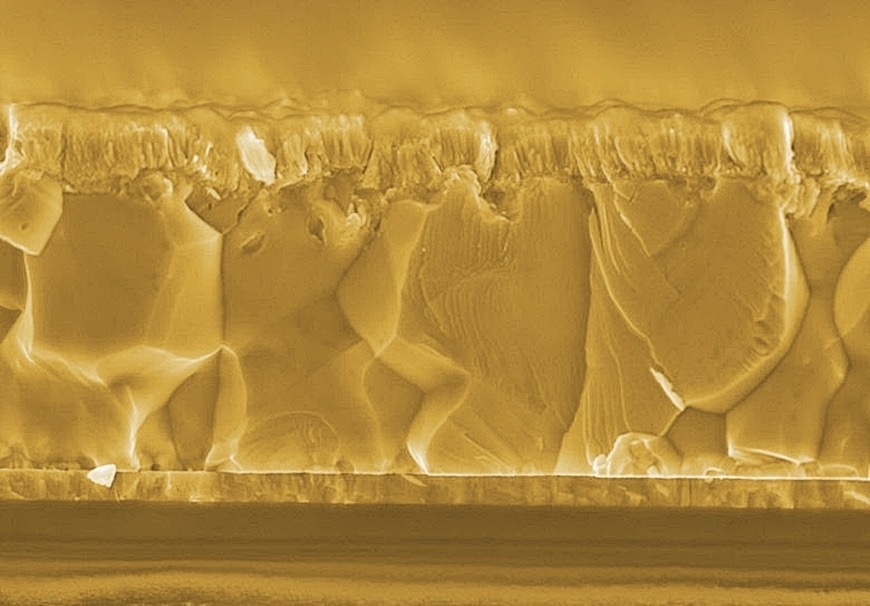

Bifacial CIGS solar cells consist of very thin layers, only 3 µm in total for the active materials. Deposit-ed on top of a transparent electrical contact, the CIGS polycrystalline layer absorbs the light from both front and back sides. Image Credit: Empa

Bifacial CIGS solar cells consist of very thin layers, only 3 µm in total for the active materials. Deposit-ed on top of a transparent electrical contact, the CIGS polycrystalline layer absorbs the light from both front and back sides. Image Credit: Empa

Empa researchers have now created a new low-temperature production technique that achieves record efficiencies of 19.8% for front illumination and 10.9% for rear illumination. Furthermore, they created the first bifacial perovskite-CIGS tandem solar cell, allowing for even better energy yields in the future. The study was published in Nature Energy.

The concept is as easy as it is simple: Direct sunlight and its reflection gathered via the back end of the solar cell enhance its energy yield. Building-integrated photovoltaics, agrivoltaics (the concurrent use of land for photovoltaic power generation and agriculture), and vertically or high-tilt mounted solar modules on high-altitude grounds are examples of possible applications. Here comes the bifacial solar cell. According to the International Photovoltaic Technology Roadmap, bifacial solar cells might account for 70% of the total photovoltaics industry by 2030.

Though bifacial silicon wafer-based solar cells are now on the market, thin film solar cells have trailed behind. This is attributed, in part, to the relatively poor efficacy of bifacial CIGS thin film solar cells, which is caused by a key bottleneck: An optically transparent electrical contact is required for any bifacial solar cell to gather reflected sunlight on the backside.

This is accomplished by employing a transparent conductive oxide (TCO) that substitutes the opaque back contact in traditional—i.e., mono-facial—molybdenum solar cells.

A Detrimental Oxide Formation

It is here where the difficulties begin: High-efficiency CIGS solar cells are often manufactured using a high-temperature deposition technique, i.e., temperatures above 550 degrees. However, at these temperatures, a chemical reaction takes place between the gallium (of the CIGS layer) and the oxygen of the transparent back contact, resulting in an oxide.

The resultant gallium oxide interface layer obstructs the flow of sunlight-generated current, lowering the cell’s energy conversion efficiency. So far, the highest values obtained in a single cell are 9.0% for the front side and 7.1% for the rear.

It’s really difficult to have a good energy conversion efficiency for solar cells with both front and rear transparent conducting contacts.

Ayodhya N. Tiwari, Thin Film and Photovoltaics lab, Swiss Federal Laboratories for Materials Science and Technology

As a result, Ph.D. student Shih-Chi Yang in Tiwari’s lab created a new low-temperature deposition procedure that should produce substantially less gallium oxide—ideally none. They employed a trace amount of silver as a kind of secret ingredient to lower the melting point of the CIGS alloy and generate absorber layers with good electronic properties at a deposition temperature of 353 degrees.

When the researchers used high-resolution transmission electron microscopy to examine the multilayer structure with Tiwari’s former postdoc Tzu-Ying Lin, who is now at National Tsing Hua University in Taiwan, they found no gallium oxide at the interface.

The Ambitious Goal: An Energy Yield of More Than 33%

This was mirrored in a significantly improved energy conversion efficiency: the cell produced values of 19.8% for front illumination and 10.9% for rear illumination that was independently certified by the Fraunhofer Institute for Solar Energy Systems (ISE) in Freiburg/Germany—in the same cell on a glass substrate.

Furthermore, the team was successful in constructing a bifacial CIGS solar cell on a flexible polymer substrate for the first time, broadening the spectrum of potential applications due to their lightweight and flexibility. Eventually, the researchers created a bifacial “tandem” cell by combining two photovoltaic technologies: CIGS and perovskite solar cells.

Tiwari believes that bifacial CIGS technology could achieve energy conversion efficiencies greater than 33%, thereby opening up new options for thin film solar cells in the future. Tiwari is currently attempting to form a collaborative effort with important labs and companies throughout Europe to accelerate technological development and industrial manufacturability on a bigger scale.

Journal Reference:

Yang, S.-C., et al. (2022) Efficiency boost of bifacial Cu(In,Ga)Se2 thin-film solar cells for flexible and tandem applications with silver-assisted low-temperature process. Nature Energy. doi.org/10.1038/s41560-022-01157-9.