SMT Tooling, a division of PSA Systems, today announced that it will showcase its Matrix™ Automatic SMT Support Tooling system on a Hanwha/ESE printer during the 2023 IPC APEX EXPO. The company will demonstrate Matrix on the Hanwha/ESE US-2000DXH1 Screen Printer in Booth #1813 at the San Diego Convention Center in California.

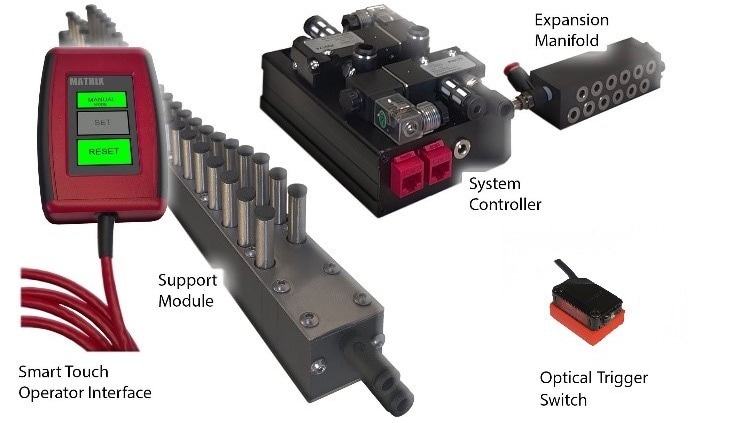

Matrix™ Automatic SMT Support Tooling system. Image Credit: PSA Systems

Matrix™ Automatic SMT Support Tooling system. Image Credit: PSA Systems

“SMT Tooling is proud to support Hanwha’s line of printers and pick-and-place machines, and has a close relationship with Hanwha to grow and develop our line of components to accommodate specific needs presented to us,” stated Jeffrey Pulaski – SMT Tooling. “We look forward to continued success for both Hanwha and SMT Tooling.”

The unique Hanwha/ESE US-2000DXH1 Screen Printer is truly one of a kind in the market. The back-to-back configurable printer allows dual-lane processing for higher throughput., bar code recognition for setup verification, paperless cleaning (with environmentally friendly quick change-out cartridges that can be replaced is less than 5-seconds), and optional auto paste dispensing.

The stable and user-friendly operator interface includes Windows 10 and a 500GB hard drive. The fast and accurate Hanwha/ESE vision system for a simultaneous recognition of PCB and stencil (3-stage lighting for PCB, 1-stage lighting for stencil); any mark can be recognized/registered; auto calibration equipped.

The Matrix system installs in minutes and includes SMT Tooling’s’ proprietary pneumatic connections for quick and easy product changeover utilizing “Smart Touch” operator interface with on-screen operator instructions and access to PSA downloadable process apps. Features include feather-lite setup force and the most rigid locking force of any system in the industry.

SMT Tooling recognized the need for a more evenly spaced pin pattern when designing the latest version and formed the support modules with a diamond shaped pin pattern that fills in the gaps that contribute to "soft spots" in the support. The Matrix diamond grid pattern is key to a more even support in turn yielding much lower rate of defects like bridging etc.

The new and improved Matrix SMT tooling solution installs on most screen printers and placers in about 30 minutes and offers fully automatic PCB support to each consecutive board.