High-efficiency and inexpensive solar cells are certain features guaranteed by perovskite semiconductors. The semi-organic material, however, is extremely sensitive to temperature changes, which can quickly cause fatigue damage in outdoor use. This can be avoided by including a dipolar polymer compound in the precursor perovskite solution.

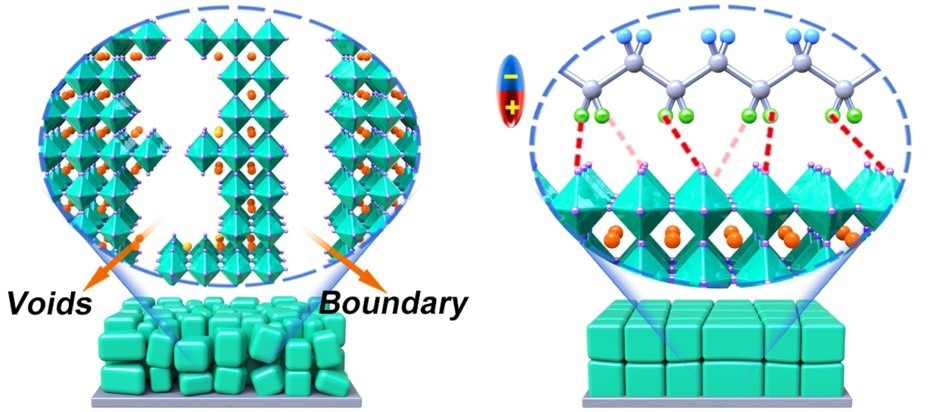

In the control perovskite layer (left), the microcrystals are not perfectly ordered and voids can form. In the new variant (right), the dipolar polymer cushions the tiny crystals and thus reduces the thermomechanical stress. Image Credit: G. Li/HZB

In the control perovskite layer (left), the microcrystals are not perfectly ordered and voids can form. In the new variant (right), the dipolar polymer cushions the tiny crystals and thus reduces the thermomechanical stress. Image Credit: G. Li/HZB

This has now been demonstrated in research by an international team led by Antonio Abate, Helmholtz Zentrum Berlin, which was published in the journal Science. The solar cells in this technique have efficiency levels well over 24% and scarcely degrade despite a hundred cycles of rapid temperature changes between –60 and +80 °C. That translates into almost a year of outdoor use.

Halide perovskites are a group of materials that hold a lot of promise for producing solar energy at even lower prices. The materials are extremely affordable, can be transformed into thin films with a small amount of energy input, and already have efficiencies that are much greater than those of traditional silicon solar cells.

The Goal: 20 Years Outdoor Stability

However, it is anticipated that solar panels will continue to produce consistently for at least 20 years outside, even when they are subject to significant temperature changes. This is something that silicon photovoltaics can handle with ease, but semi-organic perovskites quickly lose performance.

Sunlight can heat up the inside of a PV cell to 80 °C; in the dark, the cell then cools down immediately to the outside temperature. This triggers large mechanical stresses in the thin layer of perovskite microcrystals, creating defects and even local phase transitions, so that the thin film loses its quality.

Antonio Abate, Professor and Head, Young Investigator Group, Helmholtz-Zentrum Berlin

Chemical Variations Examined

Abdate has studied a chemical modification that significantly increases the stability of the perovskite thin film in various solar cell architectures, including the p-i-n architecture, which is typically a little less efficient than the more prevalent n-i-p architecture. He has executed this work with his team and several international partners.

A “Soft Shell” Against Stress

We optimized the device structure and process parameters, building upon previous results, and finally could achieve a decisive improvement with b-poly(1,1-difluoroethylene) or b-pV2F for short.

Guixiang Li, Ph.D. Student, Department Active Materials and Interfaces for Stable Perovskite Solar Cells, Helmholtz-Zentrum Berlin

The structure of b-pV2F molecules is similar to a zigzag chain with alternating dipoles.

Abate added, “This polymer seems to wrap around the individual perovskite microcrystals in the thin film like a soft shell, creating a kind of cushion against thermomechanical stress.”

Record Efficiency for p-i-n Architecture 24.6%

SEM pictures reveal that the small granules are a little closer together in the cells that have b-pV2F.

Abate further added, “In addition, the dipole chain of b-pV2F improves the transport of charge carriers and thus increases the efficiency of the cell.”

On a lab scale, they did in fact create cells with up to 24.6% efficiency, a record for the p-i-n design.

One Year Outdoor Use

Over a hundred cycles of temperatures between +80 °C and –60 °C, as well as 1000 hours of nonstop illumination equivalent to 1-sun equivalent, were applied to the newly established solar cells. That translates to around a year of outdoor use.

Abate further added, “Even under these extreme stresses, they still achieved 96 % efficiency in the end.”

The order of magnitude is already accurate. Perovskite solar modules might still provide the majority of their initial output after 20 years, which is now a target that is within reach if it is now possible to minimize the losses a little bit more.

Journal Reference:

Li, G., et al. (2023) Highly efficient p-i-n perovskite solar cells that endure temperature variations. Science. doi:10.1126/science.add7331.