Danish scientists have found a chemical procedure for disassembling the epoxy composite of wind turbine blades while extracting unbroken glass fibers and one of the epoxy resin’s original building blocks in high quality.

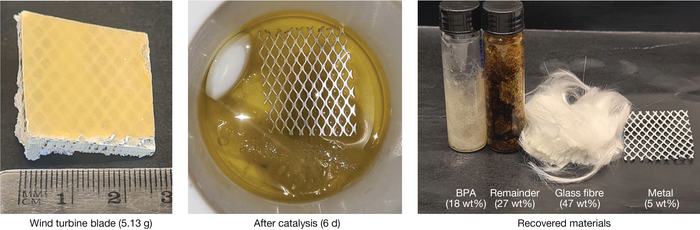

Recovery of BPA and fibers from commercial epoxy composites using Ru catalysis. Image Credit: Alexander Ahrens, Aarhus University

The new chemical technique is not confined to wind turbine blades but works on a wide range of so-called fiber-reinforced epoxy composites, including specific materials reinforced with costly carbon fibers.

The method can help to develop a possible circular economy in the wind turbine, aerospace, automotive, and space industries, where these reinforced composites are used for load-bearing structures due to their lightweight and extended endurance.

The blade’s longevity offers an environmental challenge because they are designed to last. Wind turbine blades are generally disposed of in landfills once decommissioned since they are challenging to break down.

If no solution is discovered by 2050, the world will have collected 43 million tons of wind turbine blade debris.

The newly discovered technology is a proof-of-concept recycling strategy that can be used for the great majority of existing and current wind turbine blades, as well as other epoxy-based materials.

The findings were recently published in the prestigious scientific journal Nature, and Aarhus University and the Danish Technological Institute have filed a patent application for the technique.

The researchers demonstrated, in particular, that using a ruthenium-based catalyst and the solvents isopropanol and toluene, they can separate the epoxy matrix and release one of the epoxy polymer’s original building blocks, bisphenol A (BPA), as well as fully intact glass fibers in a single process.

However, the method is not immediately scalable yet, as the catalytic system is not efficient enough for industrial implementation—and ruthenium is a rare and expensive metal. Therefore, the scientists from Aarhus University are continuing their work on improving this methodology.

Nevertheless, we see it as a significant breakthrough for the development of durable technologies that can create a circular economy for epoxy-based materials. This is the first publication of a chemical process that can selectively disassemble an epoxy composite and isolate one of the most important building blocks of the epoxy polymer as well as the glass or carbon fibers without damaging the latter in the process.

Troels Skrydstrup, Study Lead Authors and Professor, Department of Chemistry, Interdisciplinary Nanoscience Center (iNANO), Aarhus University

The study is funded by the CETEC project (Circular Economy for Thermosets Epoxy Composites), a partnership between Vestas, Olin Corporation, the Danish Technological Institute, and Aarhus University.

Journal Reference

Ahrens, A., et al. (2023). Catalytic disconnection of C–O bonds in epoxy resins and composites. Nature. doi.org/10.1038/s41586-023-05944-6.