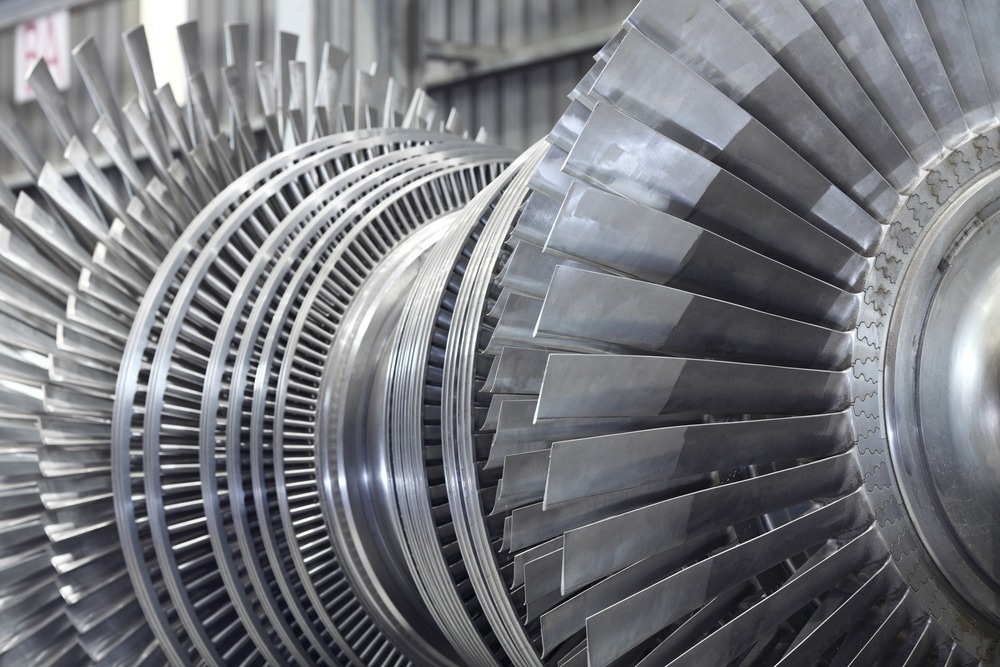

Southwest Research Institute is developing novel hydrogen combustion methods for power generation gas turbines. The designs eliminate flashback, a typical issue in hydrogen-fueled combustion systems in which the flame from the combustor passes into the nozzle, causing damage to the equipment.

Image Credit: Hywit Dimyadi/Shutterstock.com

Hydrogen fuel has various advantages, one of which is that it emits no carbon during the burning process. One of the most difficult aspects is that it is highly reactive, making it more difficult to work with than natural gas or the liquid fuels that gas turbines generally run on.

With pure hydrogen fuel, traditional low emissions designs are highly susceptible to a damaging phenomenon known as flashback. This occurs when the flame in the combustor flashes back into the nozzle, which can be damaging to the equipment.

Griffin Beck, Manager, Propulsion and Energy Machinery, Southwest Research Institute

SwRI is looking for new techniques to blend air and hydrogen within the nozzle while preventing flashback. The designs, which also have a low nitrogen oxide (NOx) emission target, were created as part of a project to promote the development of a 100% hydrogen-fueled combustion system for an industrial gas turbine.

One of the reasons hydrogen is such an attractive alternative fuel is that it does not create carbon dioxide emissions, but it does create NOx. However, if the air and hydrogen are mixed efficiently in the nozzle, the NOx emissions are significantly lower.

Griffin Beck, Manager, Propulsion and Energy Machinery, Southwest Research Institute

The nozzles work by combining air and hydrogen fuel in narrow, perpendicular paths. This design allows the air and hydrogen to combine quickly before being pressured out of the nozzle and into the combustor at flow rates that inhibit flashback.

When the right amount of air and hydrogen are mixed very well, the amount of NOx emissions is very low. Also, the air and hydrogen are forced so quickly out of the nozzle that the flame in the combustor is unable to travel backwards.

Griffin Beck, Manager, Propulsion and Energy Machinery, Southwest Research Institute

The nozzles were designed and analyzed using the substantial experience of SwRI staff from the Mechanical Engineering and Powertrain Engineering Divisions. To create, analyze, and optimize the nozzle designs, members of the interdisciplinary team used computational fluid dynamics and machine-learning techniques.

Beck concludes, “To solve this problem, we utilized the Institute’s computational and analytical tools to design and model this technology. The actual simulations we’ve been doing are extremely computationally intensive, requiring entire sections of our high-performance computing cluster for days to solve these computing problems. It’s allowed our engineers to take some unique ideas and apply them to this challenge.”