A typical chemical reaction that most people have observed has inspired a novel method of producing a flexible gel film that could lead to advancements in sensors, batteries, robotics, and other areas.

Image Credit: The University of Texas at Austin.

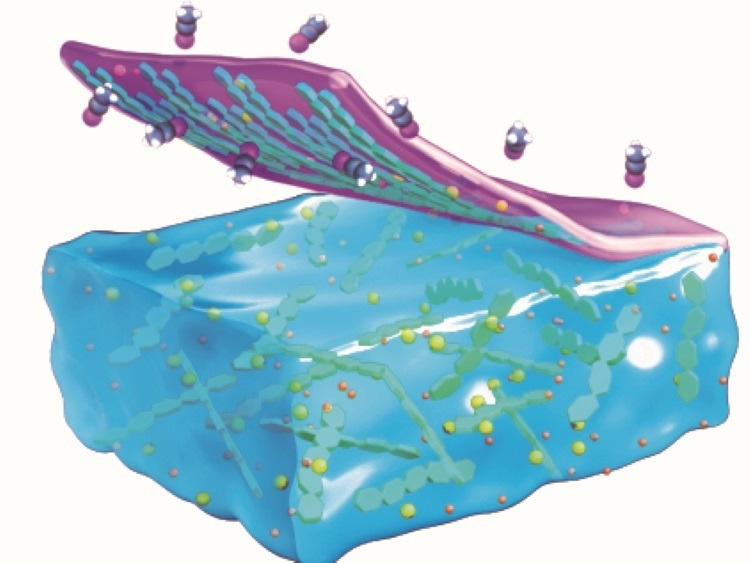

Texas Engineers guided a research team that devised a “dip-and-peel” approach for the simple and rapid manufacturing of two-dimensional ionogel membranes. When sustainable biomass materials are dipped in specific solvents, molecules spontaneously respond by assembling themselves into functional thin films at the material's edge that can be easily removed with just a pair of tweezers.

According to the researchers, this method was motivated by what happens to milk at elevated temperatures in everyday life.

In the milk-skin effect, a film forms at the outer layer of milk when it is heated. We were inspired by this phenomena and explored it in different materials to produce multifunctional gel membranes that are easy to separate.

Guihua Yu, Professor, Walker Department of Mechanical Engineering and Texas Materials Institute, Cockrell School of Engineering

The study was published in the journal Nature Synthesis.

These gels are composed of a polymer network encased in an ionic liquid. In structure, they are comparable to hydrogels, where water is the liquid element. Ionogels, on the other hand, have a less rigid structure that allows ions to move about more freely.

As a result, they are very conductive and sensitive. They have a lot of potential as sensors, maybe as part of wearable electronics that can track movements, heartbeat, and other aspects of health monitoring more accurately. They might even be used as the electrolyte in solid-state batteries, which shuttle ions back and forth to assist in charging and discharging.

The great breakthrough in the investigation is in the innovative fabrication process, which works on several different materials. The technique may be repeated hundreds or thousands of times quickly and inexpensively. Furthermore, the films can be easily manipulated to be as thick or thin as required, as well as molded or coated to other materials.

“This simple yet effective solvent-induced self-assembly method really allows rapid, and scalable production of 2D functional polymer films from different sustainable biomass materials, including cellulose, chitosan, silk fibroin, guar gum, and more,” notes Nancy (Youhong) Guo, one of the lead authors on the paper, a former Graduate Student in Yu’s lab and now a Postdoctoral Researcher at MIT.

Yu voiced his hope that other researchers will adopt this technique and apply it to a variety of technologies. The research team will continue to optimize mechanical characteristics for further applications and advanced functions for next-generation technologies like wearable electronics, smart robotics, and artificial intelligence.

Researchers from Northeast Forestry University and Shenyang University of Chemical Technology in China also participated in the study.

Journal Reference:

Zhu, Y., et al. (2023). A general strategy for synthesizing biomacromolecular ionogel membranes via solvent-induced self-assembly. Nature Synthesis. doi.org/10.1038/s44160-023-00315-5.