Korea Electrotechnology Research Institute (KERI) is a pioneering research institute for all-solid-state (sulfide-based) batteries that are free of fire and explosion hazards. Recently, it has developed a novel technology that could lead towards the mass production of affordable solid electrolytes.

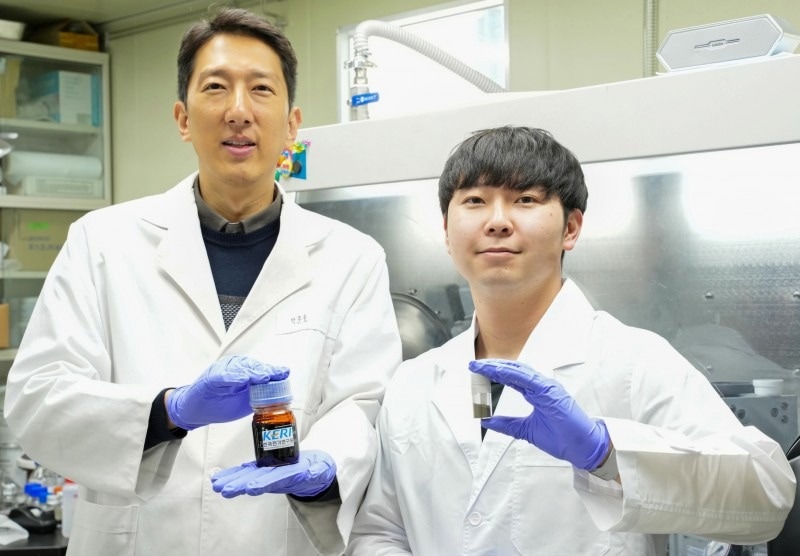

KERI Dr. Jun-Ho Park (left) and Researcher Youngjun Huh developed a low-cost, mass-production technology for sulfide solid electrolytes through a “one-pot” synthesis method. Image Credit: KERI

KERI Dr. Jun-Ho Park (left) and Researcher Youngjun Huh developed a low-cost, mass-production technology for sulfide solid electrolytes through a “one-pot” synthesis method. Image Credit: KERI

The research group headed by Dr. Jun-ho Park at the KERI’s Next Generation Battery Research Center made a “one-pot” synthesis approach to produce high-purity solid electrolytes without requiring costly lithium sulfides and additives.

For manufacturing solid electrolytes, there are two approaches: dry synthesis with the use of high-energy ball milling, and wet synthesis with the use of chemical reactions in solution. The team concentrated on wet synthesis that has benefits in mass and scale-up production and was successful in generating high-purity solid electrolytes by enhancing the synthesis reaction in a solvent.

The key benefit of this approach is that it does not need costly lithium sulfides (Li2S). Lithium sulfides are costly. They account for a maximum of 95% of the cost of starting materials for solid electrolyte production. Besides, lithium sulfides usually stay as unreacted impurities during wet synthesis, resulting in degraded cell performance.

Some have suggested lithium sulfide-free synthesis approaches, but these would need the inclusion of costly additives and often generate residual impurities, leading to unsatisfactory performance.

On the other hand, the one-pot synthesis method built by KERI facilitates the production of high-quality solid electrolytes with no lithium sulfides, additional processes, or additives. In comparison to the current lithium sulfide-based process, the material price is minimized to 1/25th and the accelerated production time would considerably add up to the mass production of solid electrolytes.

KERI’s years of experience in solid electrolyte production enabled us to find a fast and easy way to produce high-purity solid electrolytes through optimized chemical reaction combinations of starting materials in organic solvents. We are excited that this technology will help address the biggest challenges in commercializing all-solid-state batteries, namely price competitiveness and mass production issues.

Dr. Jun-ho Park, Korea Electrotechnology Research Institute

For this original technology, the KERI has filed a patent application and published papers in local and international journals. Expecting that this achievement will gain strong interest from companies building all-solid-state batteries, the institute plans to look out for opportunities for the transfer of technologies.