With the release of the latest software upgrade for its NanoOne platform of high resolution 3D-printers, UpNano has pushed the limits of the fastest 2PP 3D-printer on the market even further. Now smart stitching can improve the quality of the final product and the already high printing speed can be increased even more. Also, using the same objective and material, several completely different print jobs can be combined into one, saving costs and further time. All this is greatly simplified by an intuitive user interface that is an integral part of all software developed by UpNano. The upgrade is compatible with all NanoOne printers and most existing customers have acquired it already.

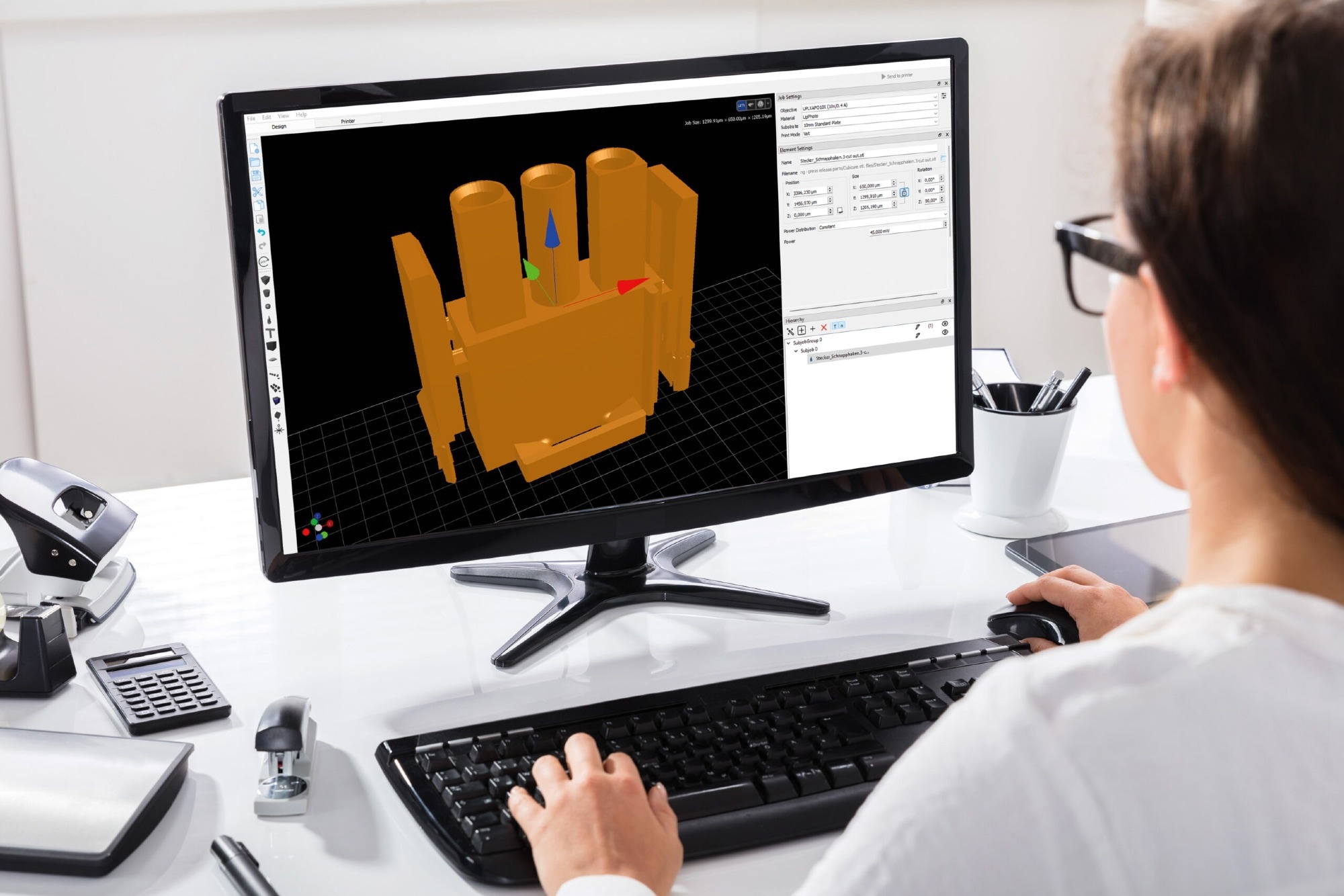

The Think3D user software supports NanoOne user in a unique, intuitive way. Image Credit: UpNano GmbH

The Think3D user software supports NanoOne user in a unique, intuitive way. Image Credit: UpNano GmbH

The 2-photon polymerization-based (2PP) 3D-printers by UpNano GmbH (Austria) are the fastest high-resolution 3D-printers on the market. Used in industry and academia alike, they have already set new standards in electronics as well as in micro-optics and for biocompatible applications in cell and medical research. The extremely compact desktop print system offers high-resolution 3D-printing across twelve orders of magnitude. Now the latest software upgrade adds significant functionality.

Seamless Progress

At the basis of the upgrade is the ability to define several printing parameters individually and set complex changes of those parameters during the printing process in advance. The potential this offers for the quality of the print product and the speed and efficiency of the printing process can be dramatic.

“Now, products with exactly defined seams can be printed”, explains Denise Hirner, COO and co-founder of UpNano. Seams are a serious quality issue for 3D-printed products. They are the result of the necessity to move the field of view during printing and to join (“stitch”) the printed elements of each subsequent field of view together. “The unique features of our latest upgrade help to reduce this”, adds Denise Hirner. “By addressing more parameters individually and dynamically, it is now possible to define the exact positions of stitching lines. Depending on the final structure, this allows for a smart integration of the seams into the design.”

Results & Resolution

Furthermore, also the resolution of the printing process can be altered as it runs. In consequence, parts that require less resolution can be printed at the lowest necessary one, together in the same printing run with elements that require much higher resolution. “One can print less defined parts quickly and step-by-step increase the resolution of the process as one comes to the finer defined structural elements”, explains Denise Hirner. “In this way very neat printing of complex structures with different requirements for resolution becomes possible and this can save up to 50% time.” The software therefore greatly enlarges the versatility of the NanoOne printer range that already benefits from the patented adaptive resolution technology allowing the widening of the laser beam by a factor of 10x for any given objective.

But using the upgrade not only can one speed up the printing of parts with different resolution requirements – one can also combine the production of different parts in one print job. A feature that allows for a further significant reduction of printing time as well as substrate use and that is yet another step towards an automated 2PP 3D-printing process. The only prerequisite is that the material and the chosen objective remain the same. “The flexibility of combining print jobs”, says Denise Hirner, “results in a much better exploitation of the substrate as more space of it can be used.” It also increases the flexibility in defining the workload of a NanoOne as now considerably more print jobs can be run over night, at weekends or other out-of-office times.

With the release of this latest software upgrade, UpNano again demonstrates its strong sense of innovation. Denise Hirner adds: “Just recently we held our annual customer event – an occasion where we always learn a lot about the evolving requirements of our worldwide customer base. With our latest software upgrade a lot of those needs are met, and we are very excited to further improve the performance of our printers together with our valued NanoOne customer network.”