A team of scientists from Ames National Laboratory and Texas A&M University developed a new way to predict metal ductility.

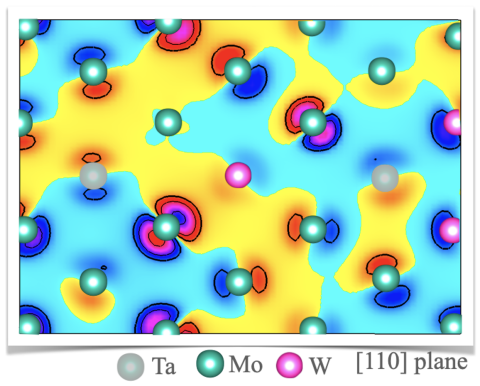

The team found that higher (increased) charge activity is responsible for improved ductility in body-centered cubic metals. The yellow region, which represents the higher electronic charge in the interstitials (area in between the atoms), corresponds to the increased charge activity that leads to higher ductility. The light blue regions are interstitials with weaker charge activity. In this image, each atom is represented by a different color, tantalum (Ta), molybdenum (Mo), and tungsten (W) as specified above. The blue, pink, and red contours show charge distribution around each site.

This quantum-mechanics-based approach fills a need for an inexpensive, efficient, high-throughput way to predict ductility. The team demonstrated its effectiveness on refractory multi-principal-element alloys. These are materials of interest for use in high-temperature conditions, however, they frequently lack necessary ductility for potential applications in aerospace, fusion reactors, and land-based turbines.

Ductility describes how well a material can withstand physical strain without cracking or breaking. According to Prashant Singh, a scientist at Ames Lab and leader of the theoretical design efforts, there are currently no robust ways to predict metal ductility. Additionally, trial-and-error experimentation is expensive and time-consuming, especially in extreme conditions.

A typical way to model atoms is with rigid spheres that are symmetrical. However, Singh explained that in real materials, the atoms are different sizes and have shapes. When mixing elements with different sized atoms, the atoms continually adjust to fit within the fixed space. This behavior creates local atomic distortion.

The new analysis incorporates local atomic distortion in determining whether a material is brittle or ductile. It also expands on the capabilities of current approaches. "They [current approaches] are not very efficient at distinguishing between ductile and brittle systems for small compositional changes. But the new approach can capture such non-trivial details, because now we have added a quantum mechanical feature in the approach that was missing," Singh said.

Another advantage to this new high-throughput testing method is its efficiency. Singh explained that it can test thousands of materials rapidly. The speed and capacity make it possible to predict which material combinations are worth taking to the experimental level. This minimizes the time and resources needed to discover these materials through experimental methods.

To determine how well their ductility test worked, Gaoyuan Ouyang, an Ames Lab Scientist, led the team's experimental efforts. They performed validation tests on a set of predicted refractory multi-principal-element alloys (RMPEAs). RMPEAs are materials that have potential for use in high temperature environments, such as aerospace propulsion systems, nuclear reactors, turbines, and other energy applications.

Through their validation testing, the team found that, "The predicted ductile metals underwent significant deformation under high stress, while the brittle metal cracked under similar loads, confirming the robustness of new quantum mechanical method," Ouyang said.

This research is further discussed in the paper, "A ductility metric for refractory-based multi-principal-element alloys," written by Prashant Singh, Brent Vela, Gaoyuan Ouyang, Nicolas Argibay, Jun Cui, Raymundo Arroyave, and Duane D. Johnson, and published in Acta Materialia.

Ames National Laboratory is a U.S. Department of Energy Office of Science National Laboratory operated by Iowa State University. Ames Laboratory creates innovative materials, technologies, and energy solutions. We use our expertise, unique capabilities, and interdisciplinary collaborations to solve global problems.

Source: DOE/Ames National Laboratory

Journal Reference: Prashant Singh, Brent Vela, Gaoyuan Ouyang, Nicolas Argibay, Jun Cui, Raymundo Arroyave, Duane D. Johnson. A ductility metric for refractory-based multi-principal-element alloys. Acta Materialia, 2023; 257: 119104 DOI: 10.1016/j.actamat.2023.119104