Scientists have produced a wide range of smart materials known as “mechanoresponsive materials” (MRMs), which respond to mechanical stimuli through fluorescence, coloring, self-healing, and self-strengthening. Mechanophores—molecules capable of conducting small-scale chemical reactions when exposed to mechanical stimuli—are one such class of materials that are being widely researched due to their potential utility in creating highly functionalized polymers.

This study can lead to novel RMs with high thermal tolerance for mechanoresponsive applications. Image Credit: Tokyo Tech

This study can lead to novel RMs with high thermal tolerance for mechanoresponsive applications. Image Credit: Tokyo Tech

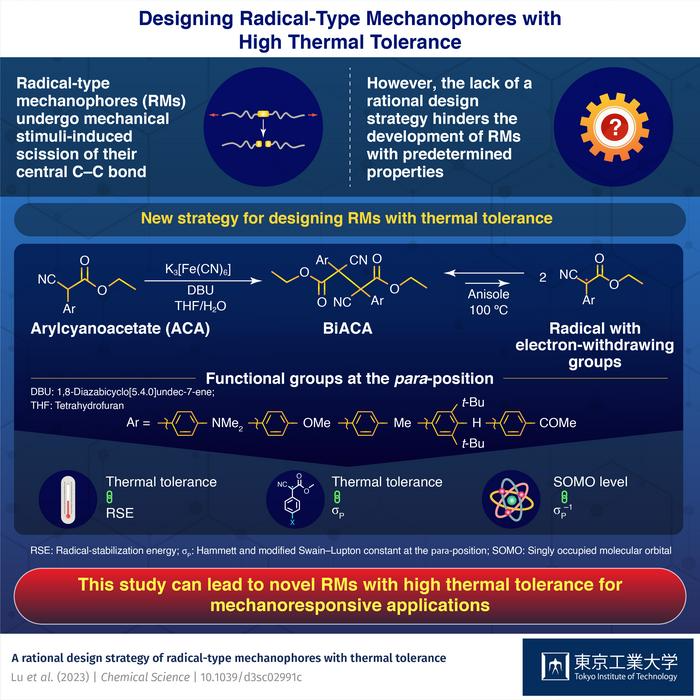

For example, mechanical stimulation can cause homolytic scission or the breaking of the core carbon-carbon (C-C) bond in radical-type mechanophores. According to the study, the type of the C-C bond frequently determines the heat tolerance, self-healing, chemical processes for polymeric material synthesis, and ambient temperature management of the generated polymer materials.

To increase RM dependability, high thermal stability must be maintained while mechanical responsiveness is maintained. However, there is a scarcity of rational design methodologies for the synthesis of new RMs.

A team of researchers led by Professor Hideyuki Otsuka from the Tokyo Institute of Technology (Tokyo Tech) overcame this issue in a recent breakthrough published in Chemical Science on August 3rd 2023. They describe a novel design technique for producing RMs with great temperature tolerance and good mechanoresponsiveness.

The relationship between thermal and mechanical scission is still unclear, which limits the development of RMs with pre-determined properties. So, we decided to investigate the factors that determine the thermal tolerance behavior of RMs.

Hideyuki Otsuka, Professor, Tokyo Institute of Technology

The group chose eight distinct radical skeletons, and for each of them, eight distinct functional groups were used as replacements.

A theoretical and experimental analysis combined revealed that for an RM series with the same radical skeleton, the thermal tolerance could be explained by two main factors: the radical-stabilization energy, which symbolizes the thermodynamic stability of the radicals during the reactions, and the Hammett and modified Swain-Lupton constants at the para-position(σp), which correspond to the functional groups’ ability to accept or withhold electrons at the para-position of an aromatic compound.

The researchers proposed that the electron-withdrawing capacity of the functional groups correlates with an increase in the thermal tolerance of RMs. By creating RMs based on bisarylcyanoacetate skeletons, they were able to effectively experimentally confirm their idea. The study also found a negative association between the σp values within an RM series based on a common skeleton and the singly occupied molecular orbital levels.

The systematic design guideline offered in this study opens up new avenues for creating innovative RMs with predetermined functions, such as high thermal tolerance and resistance to peroxidation under ambient circumstances.

Otsuka concluded, “Apart from their applications for functional materials, RMs can also facilitate the study of micro-to-macroscale mechanical stimuli, strengthened materials based on sacrificial bonds, and subsequent polymer propagation. We believe that our new design strategy will encourage scientists to explore different ways in which RMs can be used for both practical and fundamental research purposes.”

Journal Reference:

Lu, Y., et al. (2023) A rational design strategy of radical-type mechanophores with thermal tolerance. Chemical Science. doi:10.1039/D3SC02991C