Scientists from Tokyo Metropolitan University have introduced an innovative chemical process capable of upcycling polyesters, including PET found in plastic bottles, into morpholine amide.

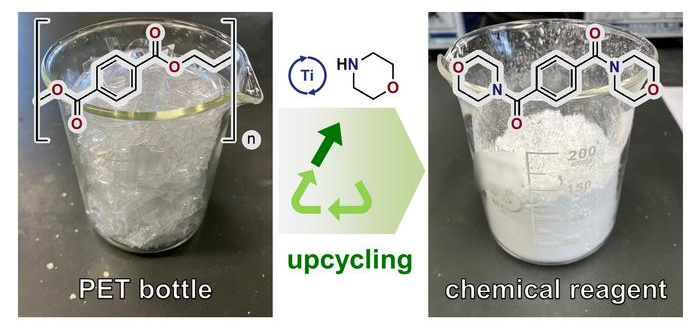

The team’s newly developed chemical process can upcycle polyesters to morpholine amides using the solvent morpholine and a small amount of titanium-based catalyst. Image Credit: Tokyo Metropolitan University

The team’s newly developed chemical process can upcycle polyesters to morpholine amides using the solvent morpholine and a small amount of titanium-based catalyst. Image Credit: Tokyo Metropolitan University

This substance serves as a versatile and valuable building block for synthesizing a wide array of compounds. The reaction achieves a high yield, generates zero waste, avoids the use of harmful chemicals, and can be readily scaled up for industrial applications. This breakthrough effectively breaks the typically expensive closed-loop recycling cycle of plastic waste, enabling the transformation of plastic into higher-value products.

Recycling plays a vital role in the battle against plastic waste, but it often comes with certain drawbacks. For instance, the recycling of polyesters, including polyethylene terephthalate (PET) from plastic bottles, frequently demands energy to elevate chemical reactions to the necessary high temperatures or relies on strongly alkaline conditions, resulting in chemical waste.

Ultimately, this process often yields intermediate compounds used to manufacture the same products they originated from. Not only can this approach be inefficient, but it can also prove economically unfeasible.

This is where "up"-cycling comes into play. Scientists have been diligently working to break free from this closed-loop recycling model and instead generate compounds from plastic waste that possess greater value and utility for society. Such an "open-loop" approach is an essential component of practical strategies designed to facilitate our transition to a more environmentally friendly society.

A team led by Associate Professor Yohei Ogiwara and Professor Kotohiro Nomura at Tokyo Metropolitan University has devised an almost waste-free technique for transforming polyesters into a versatile building block, which, in turn, can be converted into a wide range of valuable chemical compounds.

They achieved this by utilizing an inexpensive solvent known as morpholine, along with a small quantity of a titanium-based catalyst, to convert polyesters into morpholine amides.

These morpholine amides can serve a dual purpose: they can be transformed into intermediate compounds for polyester production (recycling), and they can be readily utilized to produce ketones, aldehydes, and amines—essential chemical families that play a pivotal role in the creation of numerous other, higher-value compounds (upcycling).

The new method avoids costly reagents and harsh conditions, generating minimal chemical waste. It boasts a remarkably high yield and any remaining solvent can be readily recovered. Additionally, the researchers observed that only a small catalyst quantity was necessary to maintain a reasonable reaction rate, and product separation merely required straightforward filtration.

An important point stressed by the team is that the primary reaction occurs at standard pressure, eliminating the need for specialized reaction vessels or equipment. This scalability extends seamlessly, even within a laboratory setting. To illustrate this, the team conducted an experiment using 50g of PET material extracted from an actual PET beverage bottle, reacting it with morpholine. This resulted in over 70 grams of morpholine amide, achieving a 90% yield.

With the escalating global plastic waste crisis, innovative and daring strategies are essential to effectively manage and repurpose plastics within our society. The team's low-cost, waste-free, upcycling approach holds significant potential, offering a promising solution for converting polyester waste into valuable specialty chemicals.

This research received support from a JST-CREST Grant under Grant Number JPMJCR21L5.

Journal Reference:

Yohei Ogiwara, & Nomura, K. (2023). Chemical Upcycling of PET into a Morpholine Amide as a Versatile Synthetic Building Block. ACS Organic & Inorganic Au. doi.org/10.1021/acsorginorgau.3c00037.