Polymers are huge molecules that are made by connecting a series of alike building blocks at low cost. Manufacturers find them appealing due to their cost-effectiveness and ease of processing and customization.

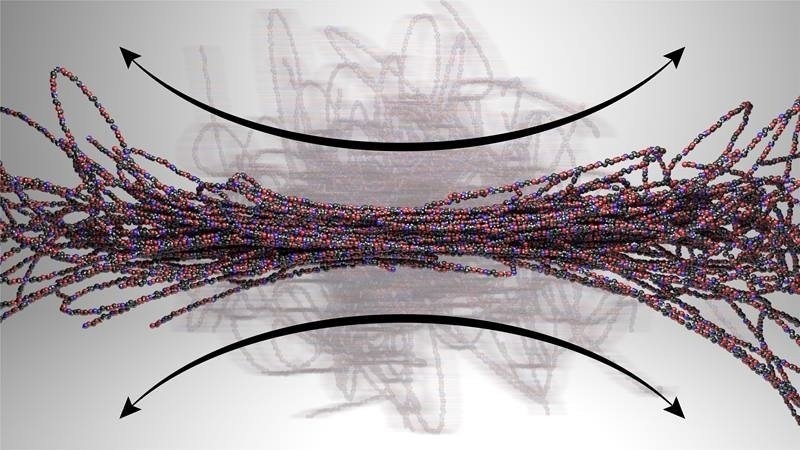

Models of polymer molecular chains illustrate the changing dynamics during melting in manufacturing. The background image suggests the many molecular configurations possible due to Brownian motion in the polymer as the chains gain freedom and deform. Image Credit: Oak Ridge National Laboratory

To broaden the scope of polymer applications and enhance their sustainability, a more comprehensive comprehension of their structural dynamics is essential. These pliable materials undergo alterations during the manufacturing process, which can significantly impact their ultimate properties and performance.

As polymers transition through different phases, such as from solid to liquid, their response to external forces becomes progressively intricate and challenging to quantify. In this study, scientists employed a combination of theoretical approaches and computational modeling to analyze molten polymers under stable flow conditions. The outcome of their research revealed universal characteristics that can be instrumental in the development of advanced polymer materials.

The Impact

The progressiveness of polymers is additive manufacturing or 3D printing. Several parts, tools, and products of establishments are made using processed soft materials at low cost. It is possible to manufacture good quality products with custom-made properties and tough shapes and assemblies. Such insights hold the potential to broaden the utilization of polymers in high-performance sectors like automotive and aerospace.

While researchers possess a solid grasp of polymer dynamics under equilibrium conditions, there is a notable gap in understanding how polymers react to variations in stress and temperature during processing. The modeling technique employed in this study empowers researchers to extract this crucial information, ultimately facilitating more precise performance predictions and the improved design of polymer materials.

Summary

Polymer materials, such as plastic and rubber, are made up of long chains of molecules that can be stimulated around by applying energy like varying the temperature or using an external force. In the huge polymer material, most of the polymer chains are knotted and collaborate via randomized motion, or Brownian motion, that can be straightly connected to noticeable properties.

For instance, car tires are more flexible at high temperatures and more rigid in cold weather. When polymers undergo melting, their behavior changes as molecular chains interact with both themselves and other chains, allowing them to move in various directions. Probability theory has been effective in characterizing polymer physics in equilibrium but falls short when describing polymers subjected to flow, which introduces added mathematical intricacies.

In this study, scientists introduced two essential methods to “fingerprint” the intricate dynamics of polymer flow. They built upon Brownian motion by incorporating complementary reference frames to analyze the individual motions of polymer chains concerning the flow. Additionally, they employed a spherical harmonic expansion technique to elucidate anisotropic movement.

Journal Reference

Shen, Z., et al. (2022). Fingerprinting Brownian Motions of Polymers under Flow. Physical Review Letters. doi.org/10.1103/physrevlett.129.057801.