Waste PCBs are an increasingly serious problem for the electronics industry as the incineration of composites and dumping in landfills cause great harm to the environment. With increased general awareness about carbon reduction, PCB manufacturers and material manufacturers are looking for new technologies to enable them to increase the recyclable content of PCBs and utilize more low-carbon raw materials. Now, Swancor introduces the answer to the PCB recycling challenge with a resin technology for copper-clad laminate (CCL) that allows the use of recycled waste plastics for CCL production.

Image Credit: Swancor

The Sustainable PCB Imperative

In today's eco-conscious world, the electronics industry faces a pressing challenge: balancing technological progress with environmental responsibility. Electronics manufacturers are seeking innovative solutions to reduce their carbon footprint and contribute to the achievement of Sustainable Development Goals (SDGs). Since PCBs are at the heart of most electronic devices, from smartphones to medical equipment, ensuring the PCB also complies with SDG initiatives is critical to comprehensive recycling efforts.

“Going green” is also becoming a legal necessity as governments tighten regulations, providing an extra push to reduce carbon emissions, conserve resources, and minimize electronic waste. Sustainable practices not only benefit the environment but also promote longer-lasting, energy-efficient electronic devices, aligning with global sustainability goals. To reduce environmental impact, meet the imperative for sustainable PCB production, create a fully circular electronics industry, and align with SDGs, PCB manufacturers should look to introduce methods to integrate low-carbon materials into production.

The revenue of Taiwan’s printed circuit board (PCB) upstream and downstream manufacturers accounts for approximately 50% of the global total. In March 2023, Chairman Li Chang-ming of the Taiwan Printed Circuit Board Association (TPCA) revealed three major initiatives for the low-carbon transformation of PCB: autonomous energy conservation, renewable energy, and carbon negative/trading. He declared Taiwan’s PCB industry’s goal to reduce emissions by 30% by 2030 and achieve net-zero emissions by 2050.

The Current State of PCB Recycling

Many PCBs end up in the landfill due to the complexity and cost of recycling. Current approaches to recycling PCBs still produce toxins and do not allow the recovery of all base materials for reuse. Also, the complexity and cost of these processes have inhibited adoption, but the necessity of innovation is still a priority. The ideal outcome is to recover as much of the original material as possible while applying the least additional input both in terms of costs and complexity of processes.

A New Approach to PCB Recycling

Founded in Taiwan in 1992, Swancor’s R&D team, with its decades of composites expertise, set out to develop a CCL solution that could both utilize recycled material for production and allow for recycling of the waste PCB. Our team successfully developed the EzCiclo low-dielectric epoxy hardener for PCBs that uses over 80% of waste plastic materials while retaining the properties of traditional hardeners. The recyclable low-dielectric hardener can be applied to the PCB to create a recyclable CCL. Applied to PCBs, it enhances the electrical properties of epoxy resin FR4 boards, achieving Dk-2.78/Df-0.011 at 10GHz after pure resin curing. Additionally, it increases the recyclable material content of PCBs, aligning with waste reduction and carbon reduction goals. At the end of the PCB’s life, the CCL made from Swancor’s EzCiclo can be decomposed by using the Swancor CleaVER chemical treatment, allowing the separation of the resin and glass fiber from the circuit board. This innovative technology is in line with the low-carbon trend, and the value-added reuse solution also reduces the terminal waste for the electronics industry. It can be applied to any product that uses a PCB, including general electronic products, in-vehicle, or network communications.

HIGHLIGHT:

- Swancor employs a chemical process to prepare active ester oligomers from waste plastics, which serve as epoxy resin hardeners.

- After curing with epoxy resin, it has excellent electrical properties and degradability.

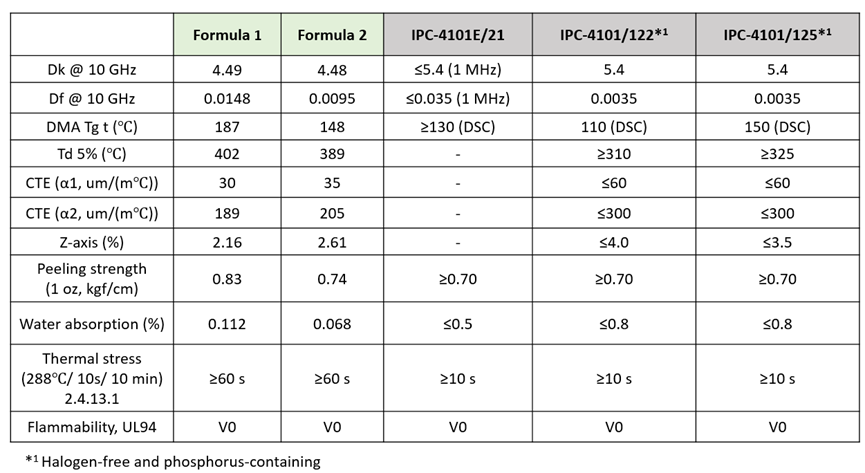

- Through collaboration with the Industrial Technology Research Institute (ITRI), Swancor has developed formulations and conducted laminate tests, the copper foil substrates can comply with IPC specifications such as IPC-4101E/21, IPC-4101/122, and IPC-4101/125.

- The copper foil substrates can be degraded through a chemical process to separate copper foil and glass cloth.

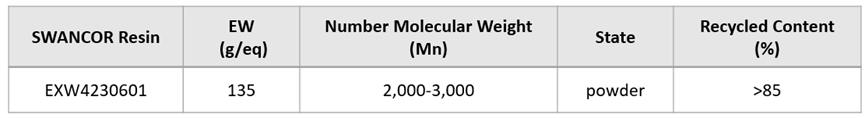

Recycled Resin Product Characteristics:

Test Results of Recycling Resin Formula:

An Effortless Path to Reaching SDGs

In a world where sustainability and circular economy are the buzzwords of the day, targets are locked on PCBs as the final step to realizing the full recyclability of electronics. By making the seamless switch to EzCiclo, PCB manufacturers can make their products recyclable and utilize recycled materials in their production processes.

These PCB recycling measures are a huge benefit to customers in the electronics industry who can also reap the benefits of better compliance with sustainable development initiatives and prepare themselves for new laws and regulations quickly being adopted and enforced around the world. Ultimately, Swancor helps both the environment and the bottom line. Swancor—Devoted to carbon neutrality and new materials innovation.