For years, researchers have dedicated extensive effort to finding economical catalysts that can replace costly metals like platinum, aiming to enhance the affordability of fuel cells.

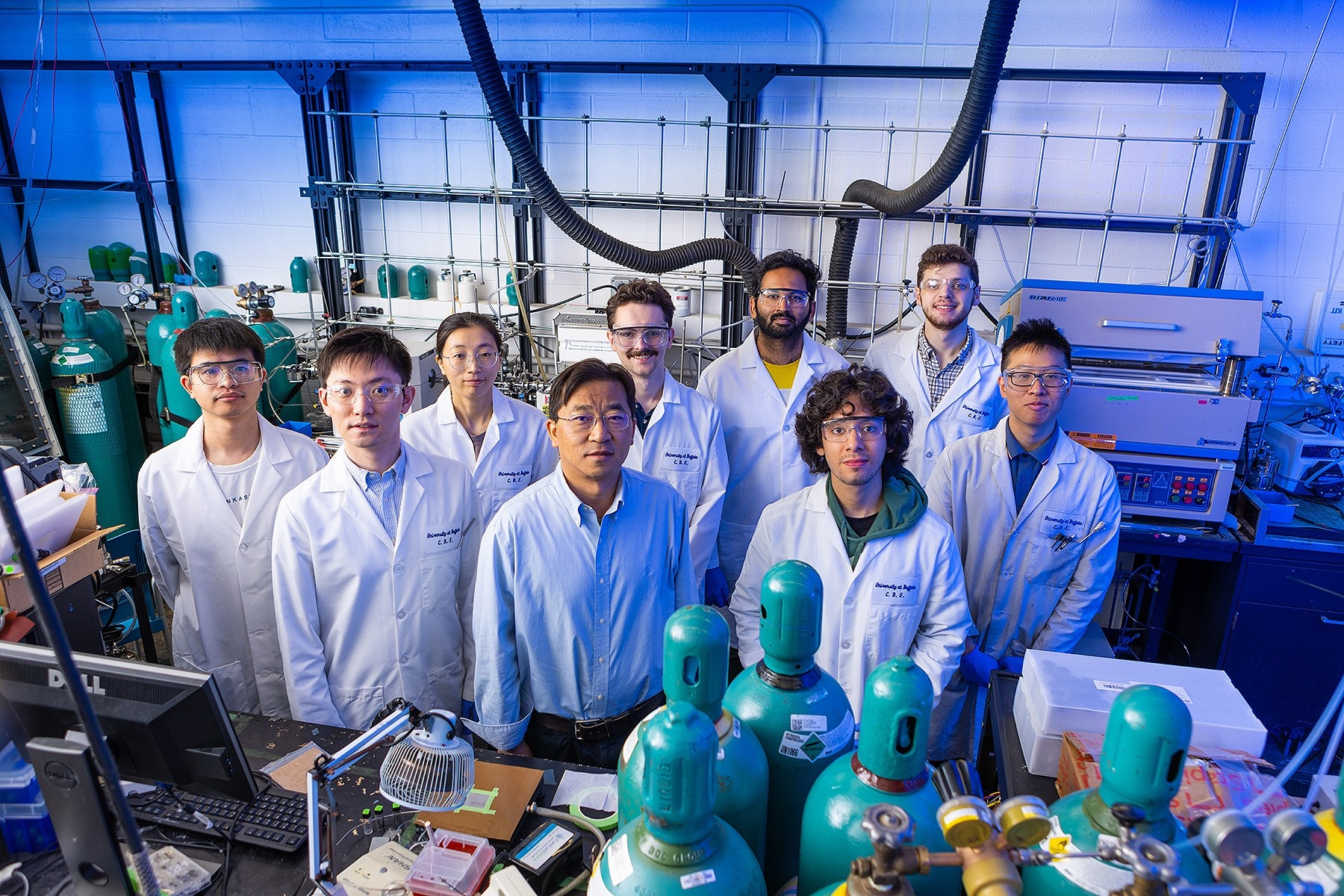

Gang Wu, front and center, is working toward reducing the costs associated with producing climate friendly fuel cells. Image Credit: Douglas Levere, University at Buffalo

Gang Wu, front and center, is working toward reducing the costs associated with producing climate friendly fuel cells. Image Credit: Douglas Levere, University at Buffalo

Thus, the scientists started their research with various combinations of three abundant and relatively inexpensive materials such as iron, nitrogen, and carbon. The outcome was irregular and unable to satisfy both the durability and efficiency simultaneously in iron-nitrogen-carbon catalyst as neither one can be achieved.

The solution is provided by a novel research spearheaded by the University at Buffalo. Researchers detail in the journal Nature Catalysis the method of introducing hydrogen into the fabrication process, resulting in a potent catalyst that closely rivals platinum's performance.

The improvement recommends a vital step in assisting fuel cell technology to live up to its potential as a pollution-free provider of electricity for cars, trucks, trains, airplanes, and other heavy-duty vehicles.

For years, the scientific community has struggled to balance this tradeoff. We can make low-cost that are effective but degrade too easily. Or we’ve made them very stable, but their performance couldn’t match platinum. With this work, we’ve taken a step toward solving this problem.

Gang Wu Ph.D., Professor and Study Corresponding Author, Department of Chemical and Biological Engineering, School of Engineering and Applied Sciences

The earlier study developed by Wu defined that iron-nitrogen-carbon catalysts were durable and unable to increase vital chemical reactions within fuel cells.

In this study, scientists tackled this constraint within the pyrolysis fabrication process, where materials are combined at exceptionally high temperatures.

Scientists bonded four nitrogen atoms to the iron in a high-temperature chamber during pyrolysis. Later, this material is embedded into a few layers of graphene, which is a tough, light, and flexible form of carbon.

This process generally happens within a chamber featuring an inert gas, such as argon. However, scientists have now provided hydrogen into the chamber to produce a mixture of 90% argon and 10% percent hydrogen.

Consequently, researchers gained greater control over the catalyst's composition, enabling the precise placement of two distinct iron-nitrogen-carbon compounds—one with 10 carbon atoms and the other with 12 carbon atoms—in strategic positions that bolstered durability and efficiency.

The resulting catalyst achieved initial fuel cell performance above the Department of Energy’s goal for 2025. Additionally, its durability surpassed most iron-nitrogen-carbon catalysts, nearing the resilience of a common low-platinum cathode employed in fuel cells.

The team included members from the following organizations: Argonne National Laboratory; Indiana University–Purdue University Indianapolis; the National Institute of Scientific Research in Vareness, Quebec; Oak Ridge National Laboratory; Oregon State University; the University of Pittsburgh; and the University of South Carolina in addition to UB.

The study is funded by the US Department of Energy.

Journal Reference:

Zeng, Y., et al. (2023). Tuning the thermal activation atmosphere breaks the activity–stability trade-off of Fe–N–C oxygen reduction fuel cell catalysts. Nature Catalysis. doi/s41929-023-01062-8.