One of the most essential materials in contemporary life is plastic, which is predicted to create 1.23 billion tons by 2060 from an annual production of 460 million tons.

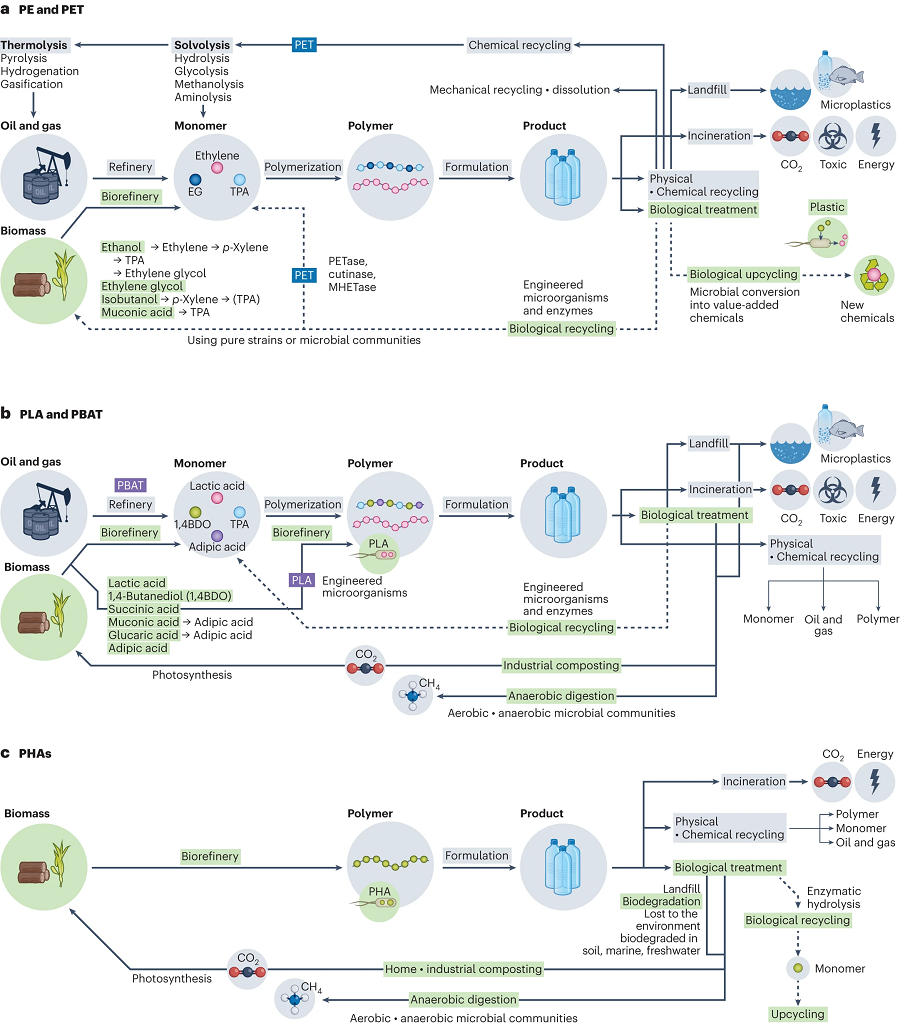

Life cycle of plastics produced using microbial biotechnologies. Image Credit: Korea Advanced Institute of Science and Technology

Nonetheless, over 6.3 billion tons of plastic waste have been produced since 1950, and it is estimated that over 140 million tons of plastic debris have accumulated in aquatic environments. The severity of microplastic pollution has recently come to light.

It not only endangers human health and the marine ecosystem, but it also exacerbates global warming by suppressing the activity of marine plankton, which is crucial in reducing the Earth’s carbon dioxide concentration.

The latest technologies for plastic production and waste plastic processing using microorganisms were carried out by a research team led by distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering. KAIST President Kwang-Hyung Lee made the announcement.

A legally binding agreement with the aim of eradicating plastic pollution by 2024 has been reached by 175 countries as part of the international community’s efforts to address the plastic problem. A number of methods, including biotechnology utilizing microorganisms, are being developed for the manufacture and processing of sustainable plastics.

The ability of microorganisms to naturally produce or break down specific compounds is enhanced by biotechnologies like metabolic engineering and enzyme engineering, which enable the production of plastics from renewable biomass resources rather than fossil raw materials and the breakdown of waste plastics.

As a result, the study team provided an in-depth analysis of the most recent microorganism-based technologies for the environmentally friendly synthesis and degradation of plastics and demonstrated how the team genuinely helped to address the plastic crisis. The team then discussed the technology drawbacks, opportunities, and future approaches to create a circular economy for plastics.

Widely used synthetic plastics like polyethylene (PE) and promising bioplastics like natural polymers derived from microorganisms (polyhydroxyalkanoate, or PHA) that are fully biodegradable in the natural environment and do not pose a risk of microplastic generation are among the plastics that can be produced using microorganism-based technologies.

The newest innovations and the state of commercialization are also covered. Furthermore, the utilization of microorganisms and their enzymes for the disintegration of plastics and the subsequent upcycling process to transform the enzymes into other valuable chemicals are presented, underscoring the competitiveness and promise of microorganism-based technology.

First author So Young Choi, a Research Assistant Professor in the Department of Chemical and Biomolecular Engineering at KAIST, says, “In the future, we will be able to easily find eco-friendly plastics made using microorganisms all around us.”

Plastic can be made more sustainable. It is important to use plastics responsibly to protect the environment and simultaneously achieve economic and social development through the new plastics industry, and we look forward to the improved performance of microbial metabolic engineering technology.

Sang Yup Lee, Corresponding Author, Distinguished Professor, Korea Advanced Institute of Science and Technology

Development of Platform Technologies of Microbial Cell Factories for the Next-Generation Biorefineries Project (2022M3J5A1056117) and the Development of Platform Technology for the Production of Novel Aromatic Bioplastic Using Microbial Cell Factories Project (2022M3J4A1053699) by the Korean Ministry of Science and ICT funded the research.

Journal Reference

Choi, S. Y., et al. (2023). Sustainable production and degradation of plastics using microbes. Nature Microbiology. doi.org/10.1038/s41564-023-01529-1.