Scientists have created an innovative, environmentally friendly substance known as "mycelium-based composites (MBCs)." These MBCs are gaining recognition for their distinctive qualities, making them a growingly favored option across different sectors, especially in applications prioritizing sustainability and minimal environmental impact.

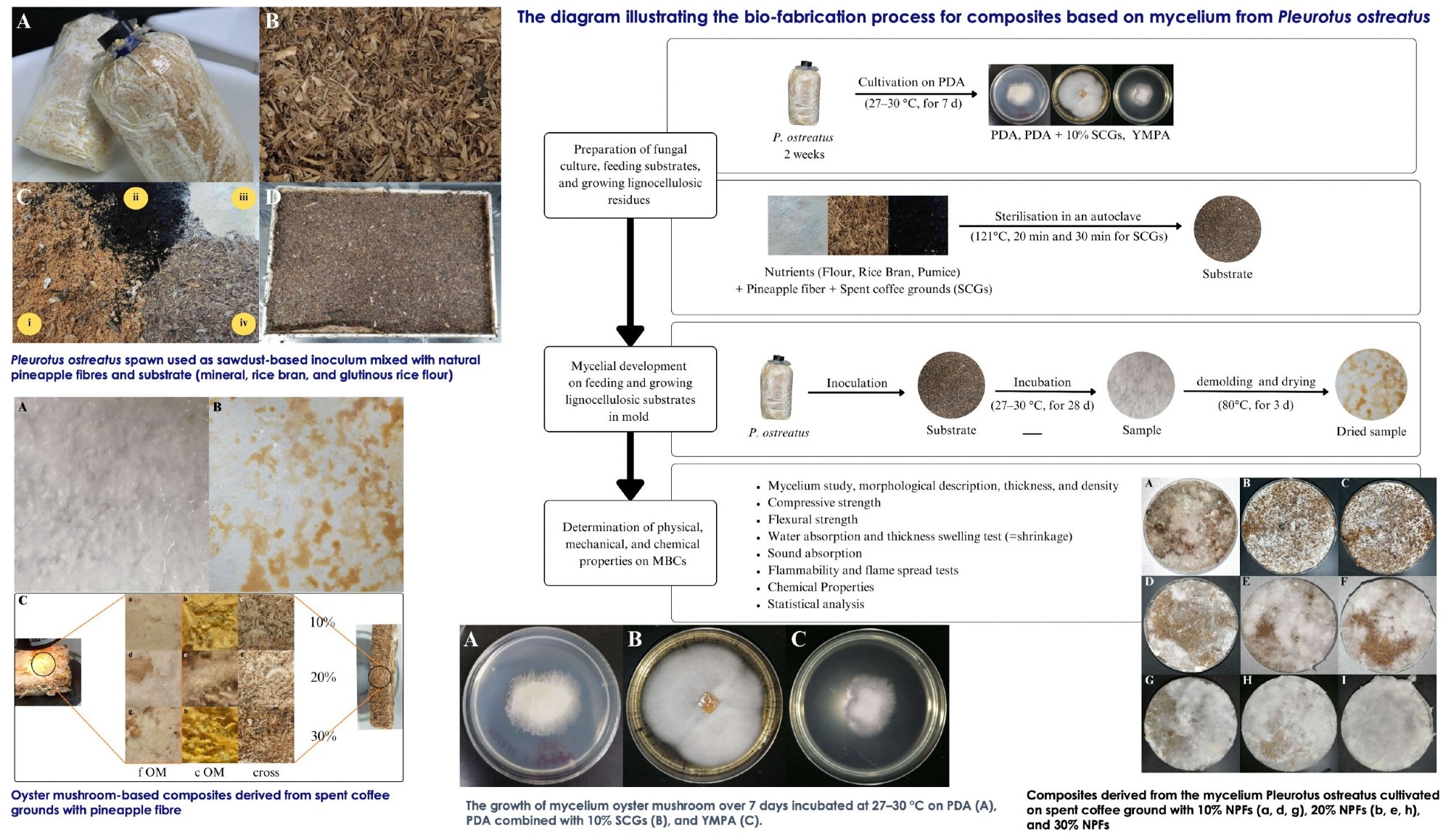

Mycelium-based composites created from Pleurotus ostreatus, grown on spent coffee grounds (SCG) as the primary substrate, are enhanced with natural pineapple fibers (NPFs). These NPFs are mixed with SCGs in varying ratios (from 10% to 30%) to investigate their effectiveness in enhancing the properties of the MBCs. Image Credit: Dr Nattawut Boonyuen, National Center for Genetic Engineering and Biotechnology (BIOTEC)

Mycelium-based composites created from Pleurotus ostreatus, grown on spent coffee grounds (SCG) as the primary substrate, are enhanced with natural pineapple fibers (NPFs). These NPFs are mixed with SCGs in varying ratios (from 10% to 30%) to investigate their effectiveness in enhancing the properties of the MBCs. Image Credit: Dr Nattawut Boonyuen, National Center for Genetic Engineering and Biotechnology (BIOTEC)

The study was published in the journal Mycology.

The biodegradability of MBCs is one of the unique qualities. In contrast to many synthetic materials, MBCs have the ability to decompose into safe, natural substances during the end of their lifecycle, which drastically reduces waste and environmental impact.

MBCs are produced in a sustainable manner by nature. Since mycelium, the fungal root structure, can grow on a variety of organic waste materials, these composites are made from renewable resources. This method not only recycles waste but also guarantees that MBCs are produced in an environmentally friendly manner by using less energy than conventional plastics and synthetic materials.

The physical characteristics of MBCs are very flexible. The density and strength can be altered to meet the needs of a variety of applications, such as stronger building materials and lightweight packaging. One important benefit is its versatility, which enables a multitude of applications in various settings.

Additionally, MBCs have outstanding acoustic and thermal insulation qualities by nature, which makes them a desirable choice for insulation panels in the building industry. Furthermore, these composites can become fire-resistant through specific treatments and growth conditions, improving the safety profile and increasing their use in situations where fire resistance is essential.

This ground-breaking study represents a major advancement in sustainable material sciences and is led by Dr. Nattawut Boonyuen, a mycologist from the National Center for Genetic Engineering and Biotechnology (BIOTEC) at the National Science and Technology Development Agency (NSTDA), and Dr. Pitak Laoratanakul from the National Metal and Materials Technology Center (MTEC), also at NSTDA.

Working with researchers from King Mongkut’s Institute of Technology Ladkrabang (KMITL) and King Mongkut’s University of Technology Thonburi (KMUTT), this creative study led by Dr. Nattawut Boonyuen produced a novel material that combines leftover coffee grounds and oyster mushroom mycelia, which is a major development in the packaging and construction industries.

This special mixture, further enhanced with real pineapple fibers, represents a significant advancement in creating sustainable materials. The properties of the composite can be changed, from enhanced strength to better water resistance, by varying the percentage of pineapple fibers added to the material. Its versatility is demonstrated by the wide range of applications it can be applied to and thanks to its adaptability.

The MBCs’ ability to withstand fire serves as additional evidence of their usefulness, combining environmental sustainability with security. Because such a combination is uncommon in the material sciences, this feature of the composites is especially noteworthy.

This advancement represents a substantial step toward sustainable living rather than merely being a breakthrough in environmentally friendly materials. It is a prime example of the extraordinary potential that results from the union of scientific inventiveness and natural elements. The use of coffee grounds and mushrooms could be the start of a larger environmental revolution as we continue to explore these materials.

Journal Reference:

Kohphaisansombat, C., et al. (2023) Fabrication of mycelium (oyster mushroom)-based composites derived from spent coffee grounds with pineapple fiber reinforcement. Mycology - An International Journal on Fungal Biology. doi.org/10.1080/21501203.2023.2273355

Source:

Tsinghua University Press