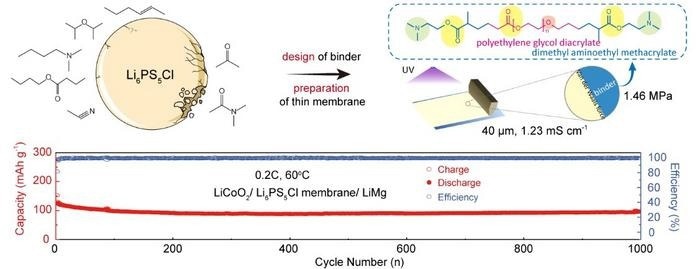

The existing inorganic solid electrolyte membranes typically face challenges such as substantial thickness in the range of hundreds of micrometers and low ionic conductivity. These limitations adversely affect the energy density and cycle life of all-solid-state lithium batteries. To address these issues, the current study utilizes wet coating techniques to produce thin membranes of Li6PS5Cl solid electrolyte.

Scientists from Ningbo Institute of Materials Technology and Engineering, CAS developed LI6PS5Cl electrolyte thin membrane and its electrochemical performances in All-Solid-State lithium battery. Image Credit: Xiayin Yao, Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences (CAS)

The study was published in the journal Energy Material Advances.

The development of thin sulfide solid electrolyte layers is imperative, although sulfide solid electrolyte is easy densified through cold pressing method, the freestanding membrane generally show a thickness greater than 500 μm. The thick and heavy layer of sulfide electrolyte results in less than expected cell-level energy density.

Xiayin Yao, Professor and Study Author, Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences (CAS)

Yao elaborated on the challenge of developing ultra-thin sulfide electrolyte membranes, highlighting their tendency to fracture during cycling due to their inherent brittleness. This fragility can result in short circuits within the battery.

Yao said, “Inspired by the binder-assisted electrode fabrication in conventional lithium-ion batteries. Combining polymeric binders with sulfide solid electrolytes is a promising strategy to prepare thin sulfide solid electrolyte layers with high mechanical strength.”

Nevertheless, because of the sensitivity of the sulfide solid electrolyte particle, a slurry-based system has not yet been fully created. Desirable polymeric binders should, in general, have enough adhesion power to adjust to volume variations during cell cycling without compromising the functionality of the sulfide solid electrolyte.

Meanwhile, weakly polar organic solvents such as toluene, xylene, heptane, ethyl acetate, etc., are the only solvents available due to the chemical instability of sulfide solid electrolytes. The stability and appropriate adhesion between polymeric binders and sulfide solid electrolyte particles are challenging to balance.

Yao said, “The design of polymer binders with suitable solvents is rarely reported for the preparation of sulfide solid electrolyte membranes through wet method.”

The polarity of solvent is the primary factor to consider its compatibility with sulfide solid electrolyte, which is related to the functional groups contained and the structure of molecular. However, for different sulfide solid electrolytes, the polarity cannot reflect the same compatibility of electrolyte with solvents.

Xiayin Yao, Professor and Study Author, Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences (CAS)

Even after raising the mass loading of active ingredients to 15.2 mg cm−2, the pouch-type cells maintain their exceptional electrochemical performance. This opens up a new slurry-based technique for the manufacture of Li6PS5Cl electrolyte thin membranes in all-solid-state batteries.

Clearly, it is urgent to develop advanced binders with suitable solvents to realize ultrathin, robust, and highly ionic conductivity sulfide solid electrolyte membranes, in this paper, the interaction among solvents containing different functional groups with the Li6PS5Cl solid electrolyte were explored and a new polymeric binder with superior mechanical properties and excellent stability to Li6PS5Cl was designed.

Xiayin Yao, Professor and Study’s Author, Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences (CAS)

Yao explained, “Different from previous conventional binders, the precursors of polymer binder are easily dispersed in anhydrous acetonitrile. Through in-situ photo-polymerization, a free-standing Li6PS5Cl thin membrane with room temperature ionic conductivity of 1.23 mS cm−1 can be prepared."

Yao continued, “The assembled LiCoO2| Li6PS5Cl membrane| LiMg all-solid-state battery can stably cycle 1000 cycles at 0.2 C under 60 oC.”

Even after raising the mass loading of Li6PS5Cl active ingredients to 15.2 mg cm−2, the pouch-type cells maintain their exceptional electrochemical performance. This opens up a new slurry-based technique for the manufacture of electrolyte thin membrane in all-solid-state batteries.

The research was supported by The National Key R&D Program of China, the National Natural Science Foundation of China, Ningbo S&T Innovation 2025 Major Special Programme, Zhejiang Provincial Key R&D Program of China, Jiangsu Provincial S&T Innovation Special Programme for carbon peak and carbon neutrality and Youth Innovation Promotion Association.

Journal Reference

Zhao, X., et.al., (2024). Stable Binder Boosting Sulfide Solid Electrolyte Thin Membrane for All-Solid-State Lithium Batteries. Energy Material Advances. doi.org/10.34133/energymatadv.0074