Reviewed by Lexie CornerFeb 28 2024

Although ice-repellent coatings have been available for a while, they have always been quite sensitive and tend to separate from the surfaces they are supposed to protect easily. This deficiency has now been addressed by a research team headed by Anna Maria Coclite and Gabriel Hernández Rodríguez from the Institute of Solid State Physics at Graz University of Technology (TU Graz). They have created a coating that is extremely resistant to abrasion and ice and sticks to a wide range of materials.

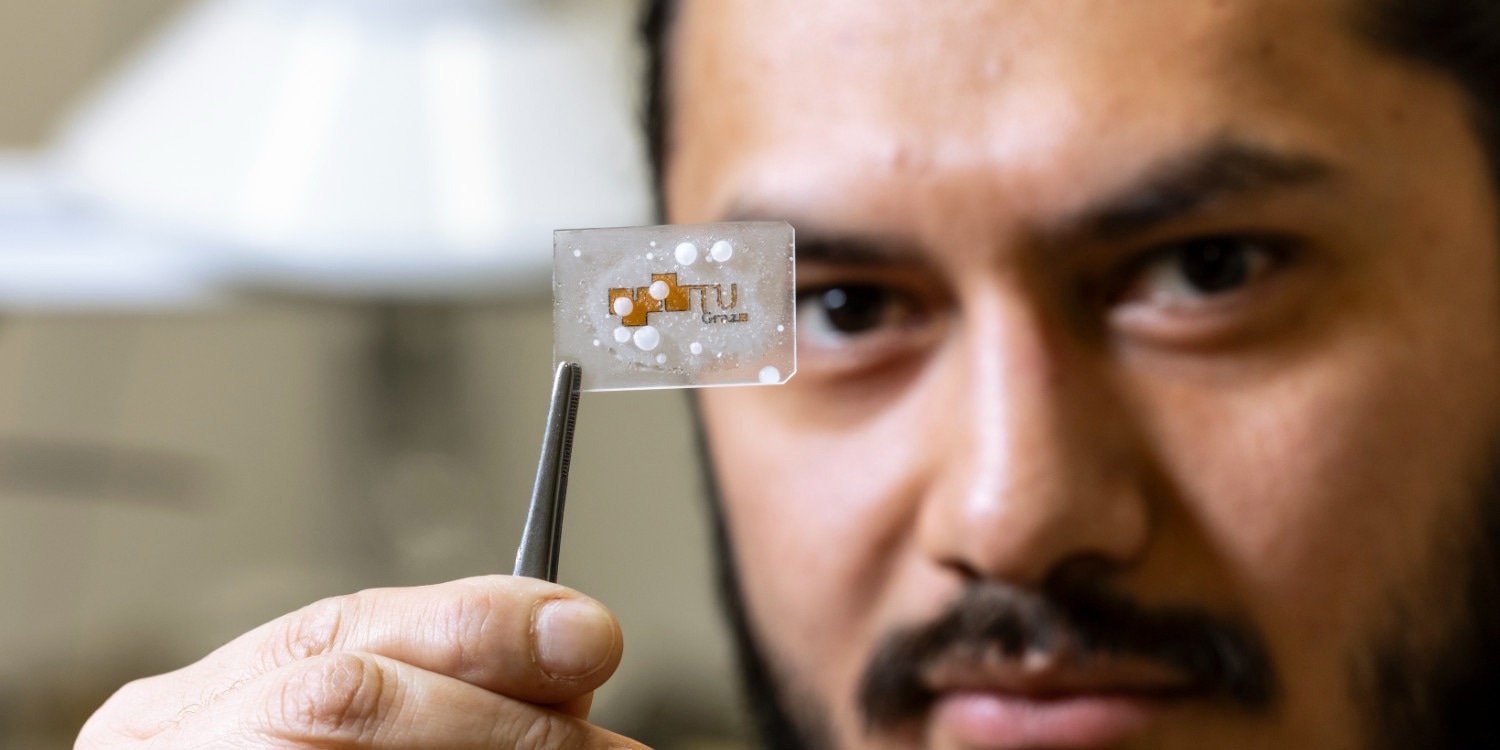

TU Graz, Gabriel Hernandez Rodriguez, icephobic coating. Image Credit: Graz University of Technology

TU Graz, Gabriel Hernandez Rodriguez, icephobic coating. Image Credit: Graz University of Technology

Gradual Transition of the Two Components

The researchers utilized a manufacturing technique called initiated chemical vapor deposition (iCVD). This facilitates the gradual conversion of the ice-repellent compound into a highly sticky priming material. This is achieved by applying the two materials to the surface to be coated as a changing gas mixture.

When applying the gas mixture, the percentage of the ice-repellent substance gradually increases from 0 % to 100 %. Initially, the gas mixture contains only the priming material. The end product is a coating that has a top side that keeps ice crystals from attaching and a bottom side that is very sticky.

Random Alignment of the Molecules Creates an Ice-Repellent Effect

Throughout their studies, Anna Maria Coclite and Gabriel Hernández Rodríguez found the basis for their coating's ice-repellent characteristic.

The ice-repellent material consists of elongated molecules that adhere to the primer in a vertical or horizontal orientation. The thicker we applied the material, the more random the alternation between vertical and horizontal molecules became. And the more random the arrangement at the surface, the greater the ice-repellent effect.

Gabriel Hernández Rodríguez, Doctoral Candidate, Graz University of Technology

This process was not previously understood. The findings were published in the ACS Applied Material and Interface journal.

Conceivable Application in Aviation and Sensor Technology

This novel coating type has a wide range of potential uses, including the aviation sector.

Such a coating could speed up the de-icing of aircraft and use less antifreeze.

Anna Maria Coclite, Professor, Graz University of Technology

Sensors exposed to the weather and affected by ice could benefit from such a coating.

Journal Reference:

Rodríguez, G. H., et. al. (2024) Icephobic Gradient Polymer Coatings Deposited via iCVD: A Novel Approach for Icing Control and Mitigation. ACS Applied Material and Interface. doi:10.1021/acsami.3c18630