Reviewed by Lexie CornerApr 10 2024

Engineered bacteria can produce a plastic modifier that makes renewable plastic easier to process, more fracture-resistant, and highly biodegradable even in seawater. The Kobe University research provides a framework for industrial-scale, adjustable material manufacture with significant promise for turning the plastic industry green.

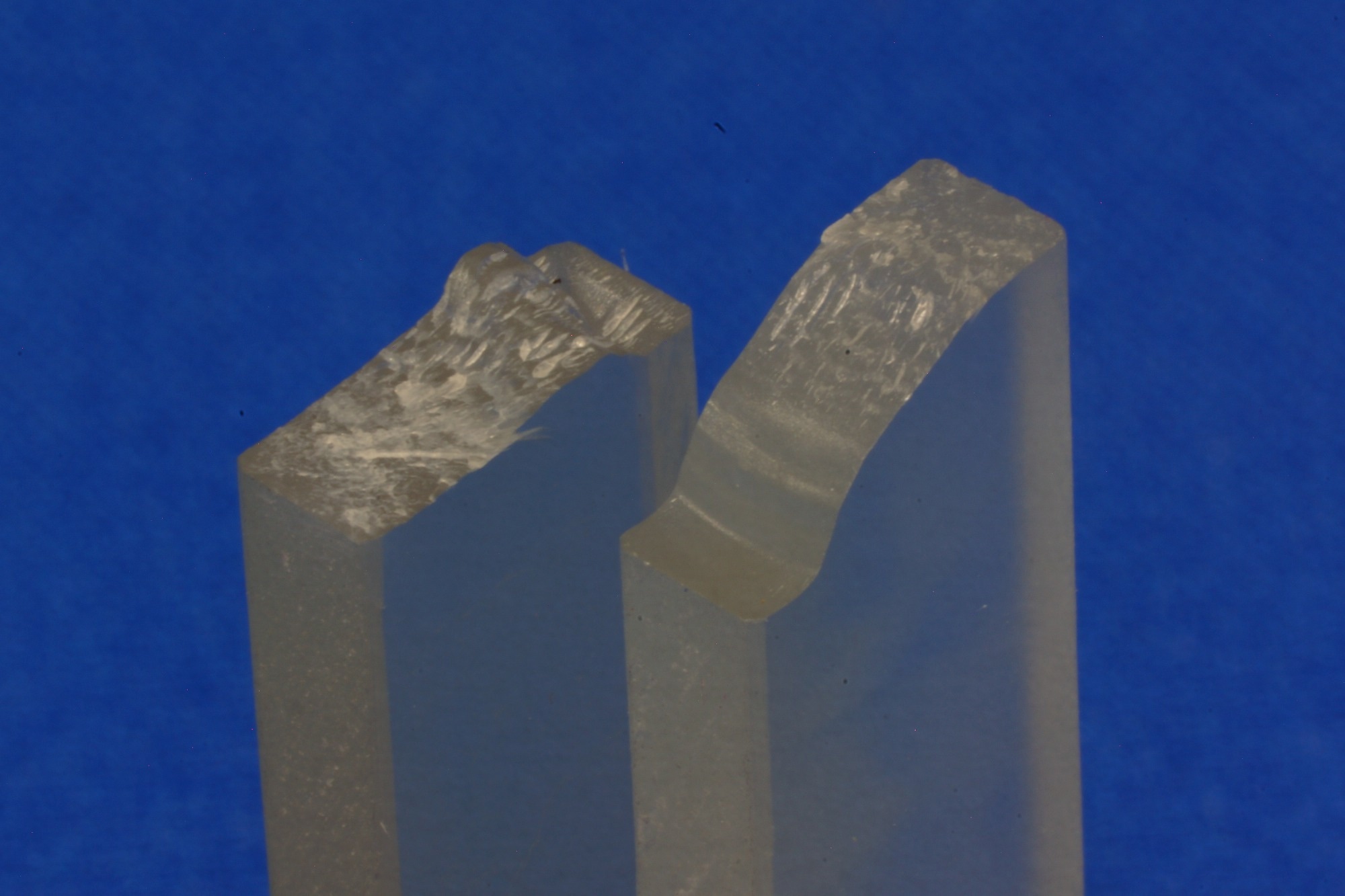

A fractured stick of lactic acid with added ultra-high molecular weight LAHB (left) exhibits obvious white discolorations at the fracture face, which is a sign of plastic deformation in toughened materials. On the other hand, pure polylactic acid (right) does not show such whitening, a sign of brittle materials. Image Credit: KOH Sangho

A fractured stick of lactic acid with added ultra-high molecular weight LAHB (left) exhibits obvious white discolorations at the fracture face, which is a sign of plastic deformation in toughened materials. On the other hand, pure polylactic acid (right) does not show such whitening, a sign of brittle materials. Image Credit: KOH Sangho

Plastic is a symbol of this society. It is a family of highly formable (hence the name), versatile, and long-lasting materials, the majority of which are also persistent in nature and, thus, contribute significantly to pollution. Many plastics are made from crude oil, which is a nonrenewable resource.

Engineers and researchers worldwide are looking for alternatives; however, no alternative has been discovered that provides the same benefits as traditional plastics while avoiding their drawbacks. One of the most promising options is polylactic acid, which may be made from plants; nevertheless, it is brittle and does not decompose well.

To overcome these challenges, a team of Kobe University bioengineers led by Seiichi Taguchi collaborated with the biodegradable polymer manufacturing company Kaneka Corporation to combine polylactic acid with another bioplastic known as LAHB, which has several desirable properties (it is biodegradable and mixes well with polylactic acid).

However, they had to deliberately manipulate the organism’s genome by adding new genes and deleting ones that interfered with it to develop a strain of bacteria that naturally generates a precursor to produce LAHB.

Published in the scientific journal ACS Sustainable Chemistry & Engineering, the team reported that they could establish a bacterial plastic factory that generates large amounts of LAHB chains using just glucose as input.

They also demonstrate that, by altering the genome, they could regulate the length of the LAHB chain and, hence, the characteristics of the resultant plastic. Therefore, they could manufacture LAHB chains up to 10 times longer than traditional procedures, which they refer to as “ultra-high molecular weight LAHB.”

Most importantly, by adding LAHB of this unprecedented length to polylactic acid, the researchers could construct a material with all of the desired qualities. The resulting extremely transparent plastic is substantially more moldable and stress-resistant than pure polylactic acid and dissolves in seawater within a week.

By blending polylactic acid with LAHB, the multiple problems of polylactic acid can be overcome in one fell swoop, and the so-modified material is expected to become an environmentally sustainable bioplastic that satisfies the conflicting needs of physical robustness and biodegradability.

Seiichi Taguchi, Researcher, Kobe University

However, the bioengineers at Kobe University have bigger dreams. The particular strain of bacteria utilized in this study can use CO2 as a raw material. Thus, it should be able to produce useful plastics directly from greenhouse gases.

“Through the synergy of multiple projects, we aim to realize a biomanufacturing technology that effectively links microbial production and material development,” Taguchi added.

Acknowledgments

The New Energy and Industrial Technology Development Organization of Japan (grant JPNP20005) commissioned this study, which was financed by the Ministry of Education, Culture, Sports, Science and Technology of Japan (grant 19K22069) and the Japan Science and Technology Agency (grant JPMJTM19YC). It was carried out in partnership with Kaneka Corporation researchers and the National Institute of Advanced Industrial Science and Technology.

Journal Reference:

Koh, S., et al. (2024) Microbial Platform for Tailor-made Production of a Biodegradable Polylactide Modifier: Ultrahigh-Molecular-Weight Lactate-Based Polyester LAHB. ACS Sustainable Chemistry & Engineering. doi:10.1021/acssuschemeng.3c07662