Researchers from Pohang University of Science and Technology showcased a novel single-crystal synthesis technology. This advancement notably enhances the durability of cathode materials used in electric vehicles. Their findings were recently published in the online edition of ACS Materials & Interfaces, a renowned international journal in the field of materials science.

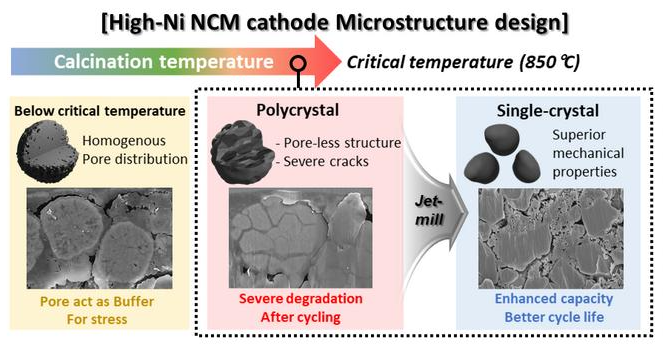

Schematic of the microstructure evolution of high-nickel cathode materials with synthesis temperature and a strategy for synthesizing single crystals at a critical temperature. Image Credit: Pohang University of Science and Technology

Professor Kyu-Young Park from the Graduate Institute of Ferrous & Eco Materials Technology and the Department of Materials Science and Engineering, along with PhD candidate Kyoung Eun Lee and alumna Yura Kim from the same institute at Pohang University of Science and Technology (POSTECH), collaborated with the POSCO Holdings N.EX.T Hub.

Lithium (Li) secondary batteries, widely employed in electric vehicles, function by converting electrical energy into chemical energy during charging and reversing the process to release electrical energy during discharge. This process involves the movement of Li+ ions between a cathode and an anode.

The cathode materials in these batteries typically include nickel (Ni) due to their high lithium-ion storage capacity. However, traditional nickel-based materials exhibit a polycrystalline structure composed of numerous small crystals. This structure is prone to structural degradation during charge and discharge cycles, leading to a considerable reduction in battery lifespan.

To tackle this issue, one proposed solution involves producing the cathode material in a "single-crystal" form. This approach aims to enhance the structural, chemical stability, and durability of nickel-based cathode materials by synthesizing them into large, single particles or "single crystals."

Single-crystal materials are typically synthesized at high temperatures, where they undergo a process of becoming rigid. However, the precise mechanisms of this hardening process during synthesis and the specific conditions under which it occurs are still not fully understood.

Image Credit: Owlie Productions/Shutterstock.com

Image Credit: Owlie Productions/Shutterstock.com

To enhance the durability of nickel cathode materials for electric vehicles, the researchers concentrated on identifying a critical temperature threshold conducive to synthesizing high-quality single-crystal materials. They conducted experiments across different synthesis temperatures to pinpoint the optimal conditions for producing single crystals in the synthesis of a specific nickel-based cathode material (N884). The team systematically evaluated how varying temperatures affected the material's capacity and long-term performance.

The researchers found that conventional polycrystalline materials synthesized below a specific critical temperature degrade over time when used in secondary batteries. In contrast, synthesizing these materials above this critical temperature enables the production of high-quality single crystals through a process known as "densification."

During densification, the internal grain size of the material increases, and empty spaces within the structure are densely filled. This transformation results in single crystals that are exceptionally hard and resistant to degradation over prolonged periods, significantly enhancing their durability.

Based on these insights, the team confirmed that synthesizing single crystals above the critical temperature represents a more advantageous strategy for material design. They also proposed an effective method for synthesizing high-quality single crystal materials.

We have introduced a new synthesis strategy to enhance the durability of nickel-based cathode materials. We will continue our research to make secondary batteries for electric vehicles cheaper, faster, and longer-lasting.

Professor Kyu-Young Park, Pohang University of Science and Technology

The research was supported by POSCO Holdings and the Basic Research Program of the Ministry of Science and ICT.

Journal Reference:

Lee, K. Y., et al. (2024). Comparison Study of a Thermal-Driven Microstructure in a High-Ni Cathode for Lithium-Ion Batteries: Critical Calcination Temperature for Polycrystalline and Single-Crystalline Design. ACS Applied Materials & Interfaces. doi.org/10.1021/acsami.4c00514.