Reviewed by Lexie CornerJul 22 2024

Researchers from the University of Delaware and Argonne National Laboratory have published a new study in JACS Au that shows how upgraded plastic waste can be effectively incorporated into electronic devices, such as silicon-based hybrid solar cells and organic electrochemical transistors.

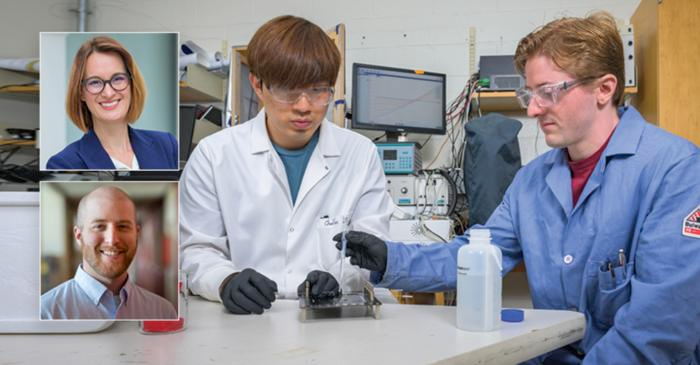

A new study by researchers at UD (from top left inset to far right) Laure Kayser, Chun-Yuan Lo, Kelsey Koutsoukos, and David Kaphan from Argonne National Laboratory (inset bottom left) conducted a study that demonstrates how waste Styrofoam can be transformed into polymers for electronic materials. Image Credit: Evan Krape/University of Delaware

A new study by researchers at UD (from top left inset to far right) Laure Kayser, Chun-Yuan Lo, Kelsey Koutsoukos, and David Kaphan from Argonne National Laboratory (inset bottom left) conducted a study that demonstrates how waste Styrofoam can be transformed into polymers for electronic materials. Image Credit: Evan Krape/University of Delaware

The researchers have discovered a chemical process that could transform Styrofoam into PEDOT:PSS, a high-value conducting polymer.

Co-author Laure Kayser’s research group regularly works with PEDOT:PSS, which has both electronic and ionic conductivity. She is an assistant professor in the Department of Materials Science and Engineering at the UD College of Engineering. She holds a joint appointment in the Department of Chemistry and Biochemistry at the College of Arts and Sciences. Her group was keen on finding a way to synthesize PEDOT:PSS from plastic waste.

The research teams at UD and Argonne started assessing the theory that PEDOT:PSS could be created by sulfonating polystyrene, a synthetic plastic present in many kinds of disposable containers and packing materials, after making contact with Argonne chemist David Kaphan during an event organized by UD’s research office.

Chemical reactions known as sulfonation, in which sulfonic acid replaces a hydrogen atom, are frequently employed to produce various goods, including drugs, dyes, and ion exchange resins. These reactions can be “soft,” which employs softer materials but is less efficient, or “hard,” which requires caustic reagents and has a greater conversion efficiency.

The researchers’ goal in this study was to identify a midway ground.

A reagent that is efficient enough to get really high degrees of functionalization but that doesn't mess up your polymer chain.

Laure Keyser, Study Corresponding Author and Assistant Professor, Department of Materials Science and Engineering, University of Delaware

First, the researchers used a technique for sulfonating small molecules that was reported in a previous study. This technique used 1,3-Disulfonic acid imidazolium chloride ([Dsim]Cl) and exhibited encouraging results in terms of efficiency and yield.

However, the researchers noted that grafting functional groups onto a polymer is more difficult than on a small molecule because, in addition to removing undesired byproducts, minor mistakes in the polymer chain might alter the polymer’s overall characteristics.

To solve this challenge, the researchers conducted months of trial and error to determine the best settings that avoided side reactions, according to Kelsey Koutsoukos, a materials science Ph.D. candidate and the study’s second author.

We screened different organic solvents, different molar ratios of the sulfonating agent, and evaluated different temperatures and times to see which conditions were the best for achieving high degrees of sulfonation.

Kelsey Koutsoukos, Study Second Author and PhD Student, University of Delaware

The researchers discovered reaction conditions that resulted in substantial polymer sulfonation, few flaws, and high efficiency, all while utilizing a moderate sulfonating agent. Additionally, because the researchers could start with polystyrene, especially discarded Styrofoam, their process effectively transforms plastic waste into PEDOT:PSS.

With PEDOT:PSS in hand, the researchers were able to compare the performance of their waste-derived polymer to commercially available PEDOT:PSS.

In this paper, we looked at two devices — an organic electronic transistor and a solar cell. The performance of both types of conductive polymers was comparable, and shows that our method is a very eco-friendly approach for converting polystyrene waste into high-value electronic materials.

Chun-Yuan Lo, Study First Author and Doctoral Student, University of Delaware

Specific investigations carried out at UD included X-ray photoelectron spectroscopy (XPS) at the surface analysis facility, film thickness analysis at the UD Nanofabrication Facility, and solar cell assessment at the Institute of Energy Conversion.

Argonne’s sophisticated spectroscopic equipment, such as carbon NMR, was employed to conduct thorough polymer characterization. Robert Opila, a professor of materials science and engineering, gave further help for solar cell study, as did David C. Martin, the Karl W. and Renate Böer Chaired Professor of Materials Science and Engineering, for electronic device performance assessments.

The researchers noted that using stoichiometric ratios throughout the process is one surprising chemistry-related discovery.

Koutsoukos added, “Typically, for sulfonation of polystyrene, you have to use an excess of really harsh reagents. Here, being able to use a stoichiometric ratio means that we can minimize the amount of waste being generated.”

The Kayser group will investigate this result further in an effort to “fine-tune” the degree of sulfonation. Thus far, their findings indicate that the degree of sulfonation on the polymer can be adjusted by adjusting the starting material ratio.

The team is interested in exploring how this fine-tuning capability can be used for other applications, like fuel cells or water filtration devices, where the degree of sulfonation has a significant impact on a material's properties. In addition, the team is investigating how this degree of sulfonation affects the electrical properties of PEDOT:PSS.

Keyser further stated, “For the electronic devices community, the key takeaway is that you can make electronic materials from trash, and they perform just as well as what you would purchase commercially. For the more traditional polymer scientists, the fact that you can very efficiently and precisely control the degree of sulfonation is going to be of interest to a lot of different communities and applications.”

Additionally, according to the researchers, the discovery has enormous potential to support current global sustainability initiatives by offering a fresh approach to transforming waste materials into materials with value added.

“Many scientists and researchers are working hard on upcycling and recycling efforts, either by chemical or mechanical means, and our study provides another example of how we can address this challenge,” Lo added.

The other study authors are Chun-Yuan Lo, Kelsey Koutsoukos, Dan My Nguyen, Yuhang Wu, David Angel Trujillo, Tulaja Shrestha, Ethan Mackey, Vidhika Damani, Robert Opila, David Martin, and Laure Kayser from the University of Delaware and Tabitha Miller, Uddhav Kanbur, and David Kaphan from Argonne National Laboratory.

Journal Reference:

Lo, C.-Y., et. al. (2024) Imidazolium-Based Sulfonating Agent to Control the Degree of Sulfonation of Aromatic Polymers and Enable Plastics-to-Electronics Upgrading. JACS Au. doi:10.1021/jacsau.4c00355