Reviewed by Lexie CornerAug 12 2024

An international research team led by Prof. Dr. Eva Blasco, a scientist at the Institute for Molecular Systems Engineering and Advanced Materials (IMSEAM) at Heidelberg University, has successfully used raw materials extracted from microalgae to create inks for printing complex biocompatible 3D microstructures. This achievement, detailed in a study published in Advanced Materials, marks the first time such materials have been used for this purpose.

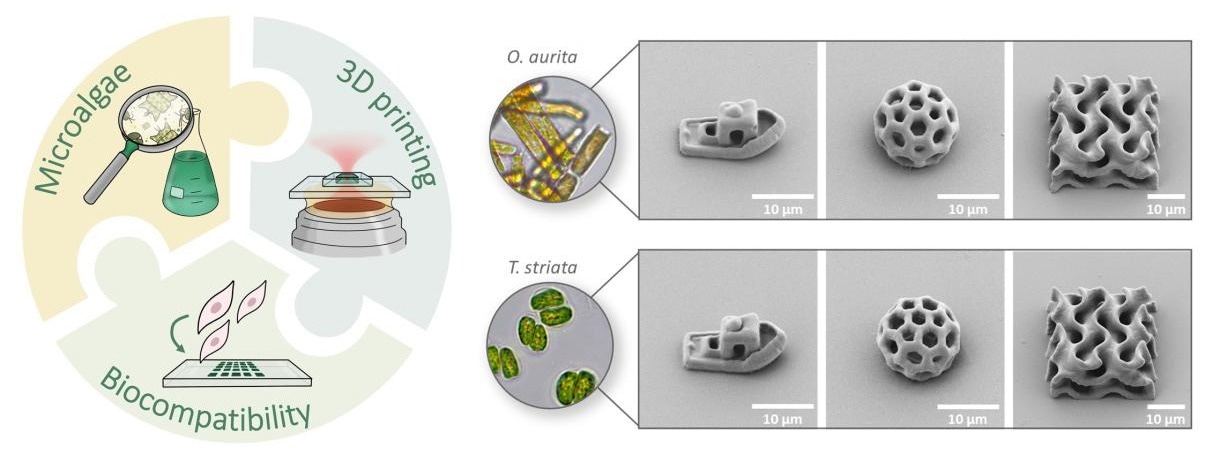

A new ink system, based on the microalgae Odontella aurita and Tetraselmis striata, enables the manufacturing of complex 3D microstructures with high quality and precision. Image Credit: Clara Vazquez-Martel

A new ink system, based on the microalgae Odontella aurita and Tetraselmis striata, enables the manufacturing of complex 3D microstructures with high quality and precision. Image Credit: Clara Vazquez-Martel

The high lipid and photoactive pigment content of microalgae, such as the diatom Odontella aurita and the green alga Tetraselmis striata, makes them ideal "biofactories" for producing sustainable materials for 3D laser printing. In the future, materials derived from microalgae could serve as the foundation for implants or scaffolds for three-dimensional cell cultures.

Two-photon 3D laser printing is an additive manufacturing method with specific benefits at the micro- and nanoscale. It offers exceptional resolution, making it valuable in fields such as biomedicine, microfluidics, optics, and photonics. The process involves focusing a laser beam on a liquid, photoreactive resin known as "ink." At the focal point, the laser light activates photoinitiators, triggering a chemical reaction that solidifies the ink locally.

Traditionally, petrochemical-based polymers have been used as inks for this precise 3D laser printing process. However, these polymers contribute to fossil fuel depletion and greenhouse gas emissions and may contain harmful components. Microalgae, with their rapid growth, CO2 fixation during cultivation, and biocompatibility, offer a sustainable alternative as "biofactories" for creating materials for 3D printing.

Despite their advantages, microalgae have hardly been considered as raw materials for light-based 3D printing.

Dr. Eva Blasco and Professor, Scientist, Institute for Molecular Systems Engineering and Advanced Materials, Heidelberg University

The research group led by Prof. Blasco operates at the intersection of 3D nanofabrication, materials science, and macromolecular chemistry. The researchers selected two species of microalgae, the diatom Odontella aurita and the green alga Tetraselmis striata, known for their high lipid content in the form of triglycerides. They extracted these triglycerides and functionalized them with acrylates to enable rapid curing under light irradiation, marking the first successful extraction of biocompatible materials from microalgae for high-resolution 3D laser printing.

The study also found that the microalgae's photoactive green pigments served effectively as photoinitiators, triggering the chemical reaction that hardens the ink into a three-dimensional structure when exposed to light.

In this way, we avoid using potentially toxic additives like the photoinitiators used in conventional inks.

Clara Vazquez-Martel, Study First Author and Doctoral Student, Institute for Molecular Systems Engineering and Advanced Materials, Heidelberg University

Using their novel ink technique, the researchers successfully created a variety of intricate 3D microstructures, including overhanging roofs and cavities. They also tested the biocompatibility of the microalgae-based inks through cell culture studies, where cells were cultivated on 3D microscaffolds for approximately 24 hours, resulting in an almost 100 % survival rate.

Prof. Blasco added, “Our results open up new possibilities not only for more sustainable 3D printing with light but also for life science applications – from 3D cell cultures to biocompatible implants.”

The study was conducted as part of the Cluster of Excellence “3D Matter Made to Order,” a collaboration between Heidelberg University and Karlsruhe Institute of Technology (KIT). Researchers from the Spanish Bank of Algae at the University of Las Palmas de Gran Canaria (ULPGC, Spain), KIT, and Heidelberg participated in the study. Funding was provided by the Fonds der Chemischen Industrie, the Carl Zeiss Foundation, the German Research Foundation, and the European Union under the European Territorial Cooperation Program.

Journal Reference:

Vazquez-Martel, C., et. al. (2024) Printing Green: Microalgae-Based Materials for 3D Printing with Light. Advanced Materials. doi:10.1002/adma.202402786