Reviewed by Lexie CornerSep 13 2024

In a study published in the Journal of Advanced Ceramics, Professor Xia Long from the Key Laboratory of Special Ceramic Design and Preparation at Harbin Institute of Technology (Weihai) proposed a conceptual framework based on reverse thinking, attempting to achieve a higher "return" with a minimum "sacrifice."

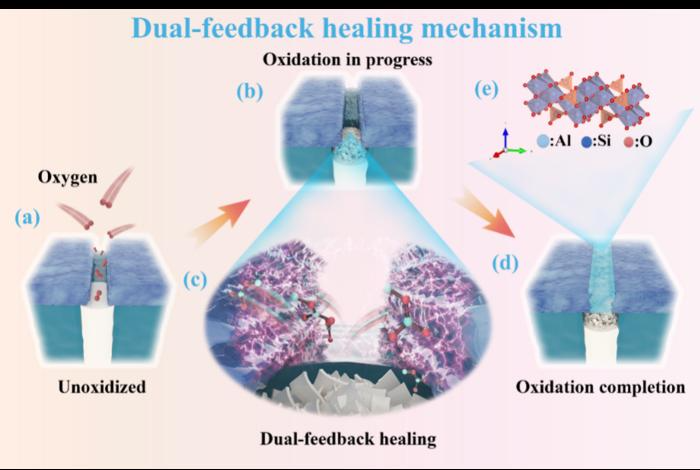

(a) Unoxidized cracks in SOAC@BNf/SiBN under an oxygen atmosphere, (b) Initial oxidation structure of SOAC@BNf/SiBN fibers under an oxygen atmosphere, (c) Microscopic dynamic process of the dual-feedback mechanism, (d) Self-healing morphology of dual-feedback cracks, (e) Crystal structure of the mullite. Image Credit: Journal of Advanced Ceramics, Tsinghua University Press

(a) Unoxidized cracks in SOAC@BNf/SiBN under an oxygen atmosphere, (b) Initial oxidation structure of SOAC@BNf/SiBN fibers under an oxygen atmosphere, (c) Microscopic dynamic process of the dual-feedback mechanism, (d) Self-healing morphology of dual-feedback cracks, (e) Crystal structure of the mullite. Image Credit: Journal of Advanced Ceramics, Tsinghua University Press

Due to their exceptional strength, toughness, and other advantageous properties, fiber-reinforced ceramic matrix composites (CMCs) have become the preferred material for radomes in hypersonic vehicles. However, oxidation caused by atmospheric oxygen at high temperatures remains a significant challenge for their advancement, with thermal protective coatings being a key solution to mitigate this issue.

The challenge arises because the different materials or fiber orientations in CMCs can cause varying rates of thermal expansion between the fibers and the matrix as temperatures fluctuate, leading to internal stresses. Ironically, these stresses make the protective coatings more prone to cracking and even peeling, which diminishes their effectiveness.

The way of the Tao moves through opposition; its function is found in what is weak.

Xia Long, Professor, Key Laboratory of Special Ceramic Design and Preparation, Harbin Institute of Technology (Weihai)

The team acknowledges the inherent challenge of preventing cracks in coatings and proposes leveraging oxidation at crack sites. The oxide products generated from this process can chemically or physically interact with the oxidation-resistant coating, reducing the material's viscosity. This self-healing process for cracks caused by thermal mismatches is referred to as the "Dual-feedback self-healing mechanism."

To validate their proposed design, the researchers used the SOAC@BNf/SiBN composite material. They applied the SOAC coating using a multi-step spray coating method. When examining the transformation of SOAC from organic to inorganic material at different sintering temperatures, the study found that no crystalline structures formed during the process, highlighting the coating's ability to adhere effectively to the substrate.

Oxidation studies on BNf/SiBN ceramics showed that oxidation begins gradually at around 1100°C. As B2O3 vapor escapes, it interacts with SiO2 in the Si-O-Al system, forming a SiO2-B2O3 glassy phase. This reduces the coating's viscosity, allowing it to flow into cracks and seal oxygen entry points. As a result, the coating effectively protects the substrate at high temperatures.

Thermal analysis data revealed that the high-temperature oxidation weight loss rate of the Si-O-Al@BNf/SiBN material system was reduced from 11 % to 2.4 %. This improvement is attributed to the dual-feedback self-healing mechanism, which helps maintain the material's mechanical properties and structural integrity in high-temperature environments.

However, a more comprehensive study is needed to explore the theoretical viability of this self-healing mechanism. Xia suggests that future research could focus on materials that promote better chemical or physical interactions between protective coatings and matrix oxidation products to further enhance the high-temperature oxidation resistance of fiber composites.

The study was co-authored by Yuanshuai Wang, Xinyu Wang, Pianpian Zhang, Anqi Lun, Yuewei Li, Yi Wang, Lizhe Xing, Zhengyang Fu, and Ya'nan Yang, all from Harbin Institute of Technology (Weihai). It was supported by the National Natural Science Foundation of China (Grant No. 51972078), the Heilongjiang Touyan Team Program, the Fundamental Research Funds for the Central Universities (Grant No. HIT. OCEF. 2021003), and the Key Laboratory of Advanced Structural-Functional Integration Materials & Green Manufacturing Technology.

Journal Reference:

Wang, Y., et al. (2024) Dual-feedback healing mechanism redefining anti-oxidation coatings in fiber reinforced composites. Journal of Advanced Ceramics. doi.org/10.26599/JAC.2024.9220966