Reviewed by Lexie CornerOct 17 2024

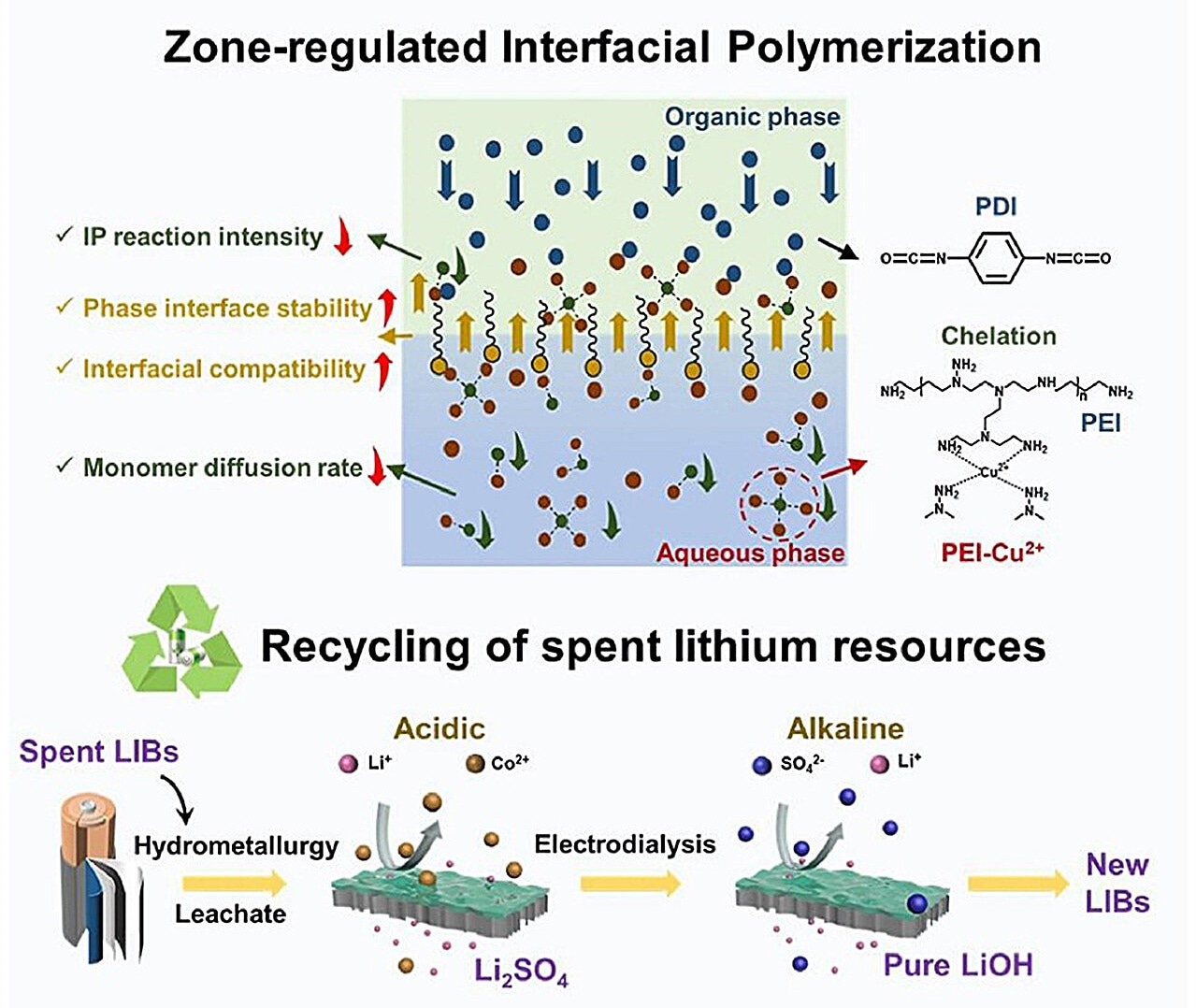

A research team led by Professor Wan Yinhua from the Chinese Academy of Sciences' Institute of Process Engineering (IPE) has developed a zone-regulated interfacial polymerization technique to create acid- and alkali-resistant nanofiltration membranes for lithium recovery from waste batteries. The study was published in the Journal of Membrane Science.

Graphical abstract. Image Credit: Journal of Membrane Science

Graphical abstract. Image Credit: Journal of Membrane Science

The need for lithium resources has increased due to the new energy sector's explosive growth, underscoring the necessity of efficiently recycling old lithium batteries. An important remedy for sustainable lithium recovery is the development of effective and environmentally friendly nanofiltration (NF) technology.

Traditional polyamide NF membranes face performance challenges, particularly in acidic and alkaline environments, leading to structural deterioration. Polyurea (PU) membranes, known for their chemical resilience, present a potential alternative for specialized separation processes. However, using polyethyleneimine (PEI) as the aqueous phase monomer in PU membrane production comes with challenges. Its multiple reactive sites cause intense interfacial polymerization, leading to irregular membrane structures and poor reproducibility, limiting its scalability for lithium recovery.

In this study, researchers propose a solution using Cu2+ as a reaction inhibitor and sodium dodecyl sulfate (SDS) as a surfactant. These components help regulate the diffusion of monomers in the bulk solution and at the phase interface, addressing the production issues.

We use Cu2+ to regulate the diffusion and reactivity of PEI, while SDS ensures even distribution at the phase interface, improving membrane integrity. Together, Cu2+ and SDS enable the formation of a thinner, more uniform PU separation layer.

Wan Yinhua, Professor, Chinese Academy of Sciences

This method enhances the uniformity of the polymerization process by precisely controlling the diffusion and interaction of monomers both at the interface and in the bulk solution. It also slows down the rapid reactivity of hyperbranched monomers, resulting in improved membrane consistency and stability across different batches.

PU membranes demonstrate exceptional chemical stability and separation selectivity, even under the harsh acidic and alkaline conditions encountered during lithium recovery from spent batteries. By balancing charge and size effects, these membranes ensure reliable performance in extreme pH environments.

Our zone-regulated interfacial polymerization strategy showcases the importance of controlling monomer diffusion behavior to improve membrane performance and manufacturing stability. This study expands the scope of PU membranes in the energy sector, offering a robust solution for sustainable lithium recovery.

Luo Jianquan, Professor and Study Corresponding Author, Chinese Academy of Sciences

This study represents a major advancement in membrane science and recycling technology, supporting international initiatives for sustainable resource use in the quickly expanding new energy sector.

Journal Reference:

Xiao, S., et al. (2025) High-performance polyurea nanofiltration membrane for waste lithium-ion batteries recycling: Leveraging synergistic control of bulk and interfacial monomer diffusion. Journal of Membrane Science. doi.org/10.1016/j.memsci.2024.123405.