Reviewed by Lexie CornerOct 22 2024

Researchers Cutler Phillippe, Francesco Panerai, and Laura Villafañe Roca of the Beckman Institute for Advanced Science and Technology explored the fiber-scale characteristics of parachute textiles and linked them to larger-scale behavior through computed tomography scans. Their research was published in the American Institute of Aeronautics and Astronautics Journal.

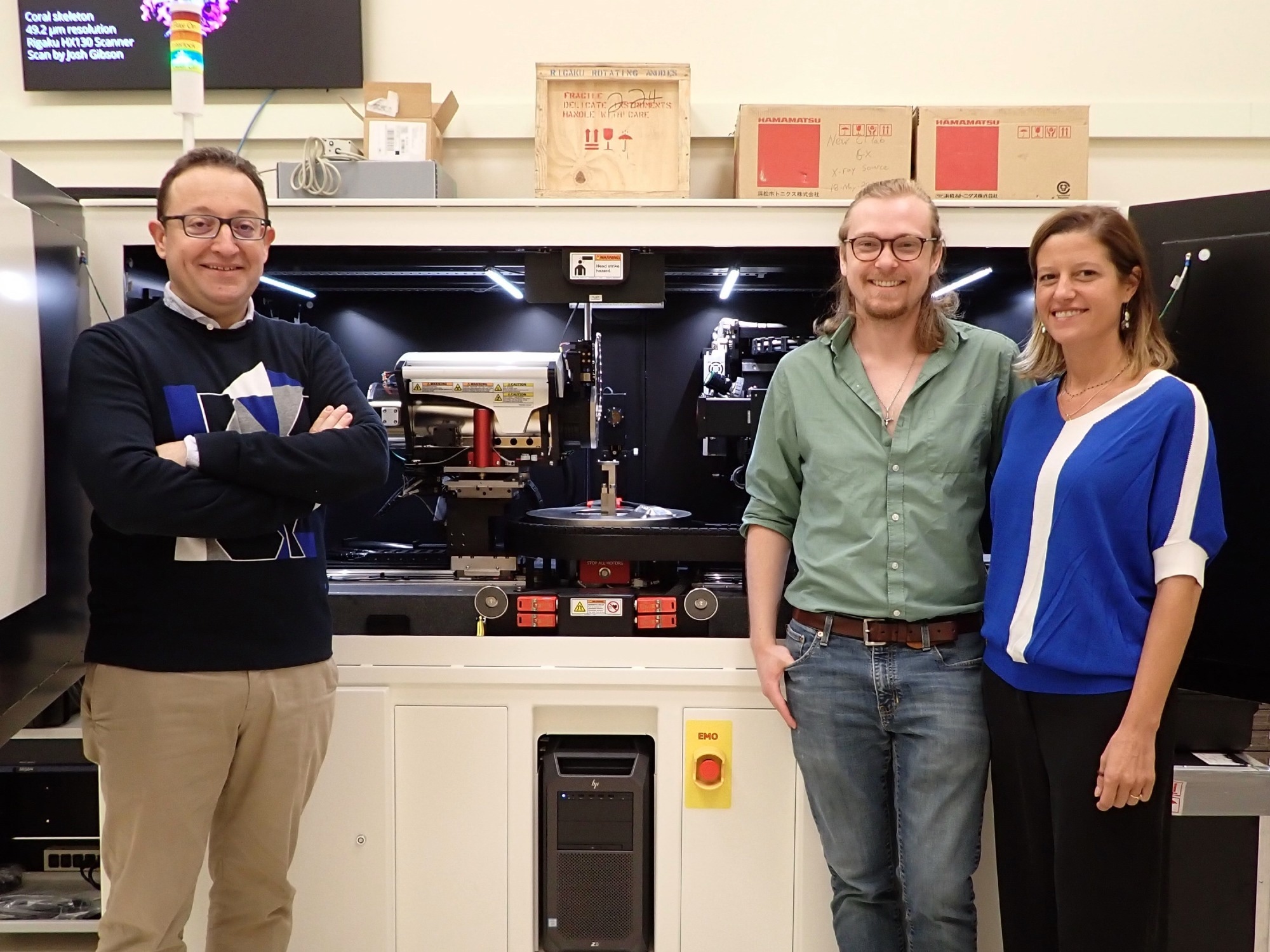

Francesco Panerai (left), Cutler Phillippe (center), and Laura Villafañe Roca in front of the micro-CT scanner at the Beckman Institute. Image Credit: Lauren Otolski, Beckman Communications Office

Francesco Panerai (left), Cutler Phillippe (center), and Laura Villafañe Roca in front of the micro-CT scanner at the Beckman Institute. Image Credit: Lauren Otolski, Beckman Communications Office

Parachutes have a wide range of applications, from slowing down skydivers to decelerating supersonic scientific payloads. Despite the varying uses, two factors remain constant: parachutes must endure significant force and are vital to ensuring the safety of what they carry. Understanding the dynamics of a parachute’s deployment and descent is essential for selecting materials that perform effectively under these demanding conditions.

We know generally how a textile impacts the performance of the parachute. But we don’t know from an experimental standpoint how that performance is related to the individual fiber motions within the textile as well as the dynamic properties of, for example, a bundle of fibers.

Cutler Phillippe, Graduate Student, Department of Aerospace Engineering, University of Illinois Urbana-Champaign

The researchers explained that if the parachute’s overall performance is considered the macroscale, then a bundle of fibers represents the mesoscale, while an individual fiber corresponds to the microscale. Their study aimed to measure the behavior at these smaller scales and connect it to the forces and interactions occurring at the larger scale. This approach provides computational modelers with valuable data on new phenomena and enables them to simulate the behavior of untested parachute designs.

Using a Beckman micro-CT scanner, the team imaged two parachute textiles under increasing stress levels. Similar to hospital CT scanners, micro-CT scanners use X-rays to capture 2D slices of a material, which can then be combined to reveal its three-dimensional structure. The researchers placed their parachute samples in a tensile tester, gradually increasing the applied force and capturing micro-CT scans at each new stress level to observe how the materials responded.

Tensile testing revealed how parachute fibers stretch, straighten, and reorganize under increasing loads, responding to varying stress levels. As the fibers reshaped, the pores between the fiber bundles widened, altering how air moves through and around the parachute.

Textiles are considered isotropic when they contain an equal amount of the same type of fibers in both directions, meaning their properties are the same vertically and horizontally. In such cases, one would expect the material to exhibit equal stress and deformation when forces are applied in any direction.

However, the researchers found the opposite. The parachute textiles exhibited different properties depending on the direction of the fibers. During the weaving process, the warp fibers (those running in one direction) are held in tension, while the weft fibers (inserted perpendicular to the warp) are woven between them. Even after the textile is removed from the loom, the manufacturing-induced tension differences cause the fabric to remain anisotropic. Specifically, the material resists stretching more along the warp fibers.

Understanding these directional differences is essential for parachute assembly. Parachutes consist of multiple textile pieces attached together, and the orientation of these pieces influences their overall performance.

Choosing the best parachute materials is critical for both safety and mission success. This research informs models that will be used to select promising candidate textiles.

Phillippe added, “Computationalist work is very good at recreating things that have been done, but it’s not quite to the deployment phase (pun intended) of being able to say, ‘Okay, I’ve modeled this new textile, and I can definitively tell you that it is or is not worth the cost to make a prototype.”

Improving parachute material screening models can significantly reduce costs and save time in the parachute industry, benefiting a range of applications, from scientific missions to relief efforts and recreational uses.

Cutler Phillippe presented his work at a symposium focused on fluid-structure interactions, where he met with NASA computationalists and other programmers who incorporated his research into their models.

“A lot of the time, there is a slight disconnect in communication between what computationalists need and what experimentalists think that they need, and you end up not completing the full picture. Getting to know everyone and becoming informed on their wants and needs was very inspiring. It really helped to frame what I need to do moving forward from this work,” Phillippe stated.

Phillippe received a NASA Space Technology Graduate Research Opportunities award to support his research. He is currently focused on imaging textiles with airflow passing through them to visualize their 3D deformation and is using microscopy imaging to better understand how textile pores affect airflow.

Journal Reference:

Phillippe, C. A. et. al. (2024) In Situ Imaging of Parachute Textile Micromechanics Under Tensile Load. American Institute of Aeronautics and Astronautics Journal. doi.org/10.2514/1.J064350