Reviewed by Danielle Ellis, B.Sc.Nov 28 2024

Researchers at the University of Virginia School of Engineering and Applied Science created a new design that seems to rewrite the polymer engineering textbook completely. It is no longer a dogma that a polymeric material's stiffness must inherently limit its stretchability. Their study was published in the journal Science Advances.

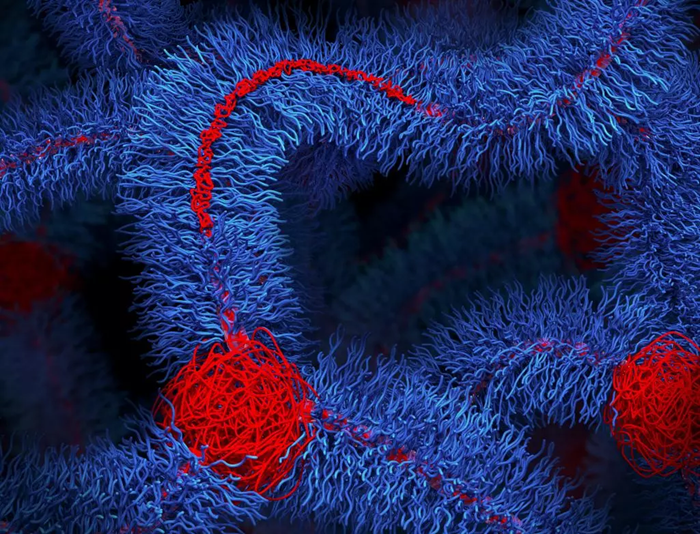

An artistic rendering of a network formed by crosslinking foldable bottlebrush polymers, which feature a collapsed backbone grafted with many flexible linear side chains. Image Credit: Soft Biomatter Lab, University of Virginia School of Engineering and Applied Science

An artistic rendering of a network formed by crosslinking foldable bottlebrush polymers, which feature a collapsed backbone grafted with many flexible linear side chains. Image Credit: Soft Biomatter Lab, University of Virginia School of Engineering and Applied Science

We are addressing a fundamental challenge that has been thought impossible to solve since the invention of vulcanized rubber in 1839.

Liheng Cai, Assistant Professor, University of Virginia

At that point, Charles Goodyear unintentionally discovered that heating sulfur-containing natural rubber produced chemical crosslinks between the rubber molecules that resembled strands. By establishing a network of polymers, this crosslinking process turns the sticky rubber, which melts and flows in the heat, into an elastic, long-lasting substance.

Since then, it has been thought that some stretchability must be given up to make a polymer network material stiff.

That was the belief until Cai’s team, led by Ph.D. Student Baiqiang Huang challenged it with their innovative “foldable bottlebrush polymer networks.” Their groundbreaking work was supported by Cai’s National Science Foundation CAREER Award.

“Decoupling” Stiffness and Stretchiness

This limitation has held back the development of materials that need to be both stretchable and stiff, forcing engineers to choose one property at the expense of the other. Imagine, for example, a heart implant that bends and flexes with each heartbeat but still lasts for years.

Baiqiang Huang, Ph.D. Student, University of Virginia

Huang Co-Authored the work alongside postdoctoral researchers Shifeng Nian and Cai.

Every product people use, from household appliances to car tires, contains crosslinked polymers. Biomaterials and medical devices are using them more and more.

Prosthetics and medical implants enhanced wearable electronics, and “muscles” for soft robotic systems that must repeatedly flex, bend, and stretch are some of the uses the team sees for their material.

Stiffness and extensibility—defined as how far a material can stretch or expand without breaking—are inherently connected because they stem from the same molecular structure: polymer strands interconnected by crosslinks. Traditionally, increasing the stiffness of a polymer network has been achieved by adding more crosslinks.

This does not resolve the stiffness-stretchability trade-off; polymer networks with more crosslinks have less deformation freedom and break more readily during stretching.

Our team realized that by designing foldable bottlebrush polymers that could store extra length within their own structure, we could ‘decouple’ stiffness and extensibility in other words, build in stretchability without sacrificing stiffness. Our approach is different because it focuses on the molecular design of the network strands rather than crosslinks.

Liheng Cai, Assistant Professor, University of Virginia

How the Foldable Design Works

Cai's structure is more like a bottlebrush than linear polymer strands, with several flexible side chains extending from a central backbone.

Crucially, the backbone can unfold as it stretches, collapsing and expanding like an accordion. The polymer's concealed length uncoils when the material is pulled, enabling it to extend up to 40 times longer than conventional polymers without degrading.

In the meantime, stretchability and stiffness can ultimately be adjusted separately because the side chains influence rigidity.

The constituents of the foldable bottlebrush polymer structure are not limited to certain chemical kinds; this approach is “universal” for polymer networks.

One of their designs, for instance, uses a polymer for the side chains that maintains its flexibility even at low temperatures. However, a gel that may replicate biological tissue can be created by substituting the side chains with a different synthetic polymer, one that is frequently utilized in biomaterial engineering.

Like many of the innovative materials created at Cai's lab, the foldable bottlebrush polymer is intended to be 3D printed. This remains true even when combined with inorganic nanoparticles, which can be engineered to display complex electric, magnetic, or optical properties.

For instance, they can incorporate conductive nanoparticles, like gold or silver nanorods, which are essential for wearable and flexible electronics.

“These components give us endless options for designing materials that balance strength and stretchability while harnessing the properties of inorganic nanoparticles based on specific requirements,” Cai said.

Journal Reference:

Huang, B., et al. (2024) A universal strategy for decoupling stiffness and extensibility of polymer networks. Science Advances. doi.org/10.1126/sciadv.adq3080.