An international group of researchers from the Beijing University of Technology, led by Professors Xiaoyan Song and Chao Hou, have proposed an innovative strategy for preparing immiscible bimetals to achieve superior mechanical properties and electrical conductivity. It applies to various composites for outstanding multi-objective properties by manipulating the configuration and microstructure of the main phases. The journal Engineering published this study.

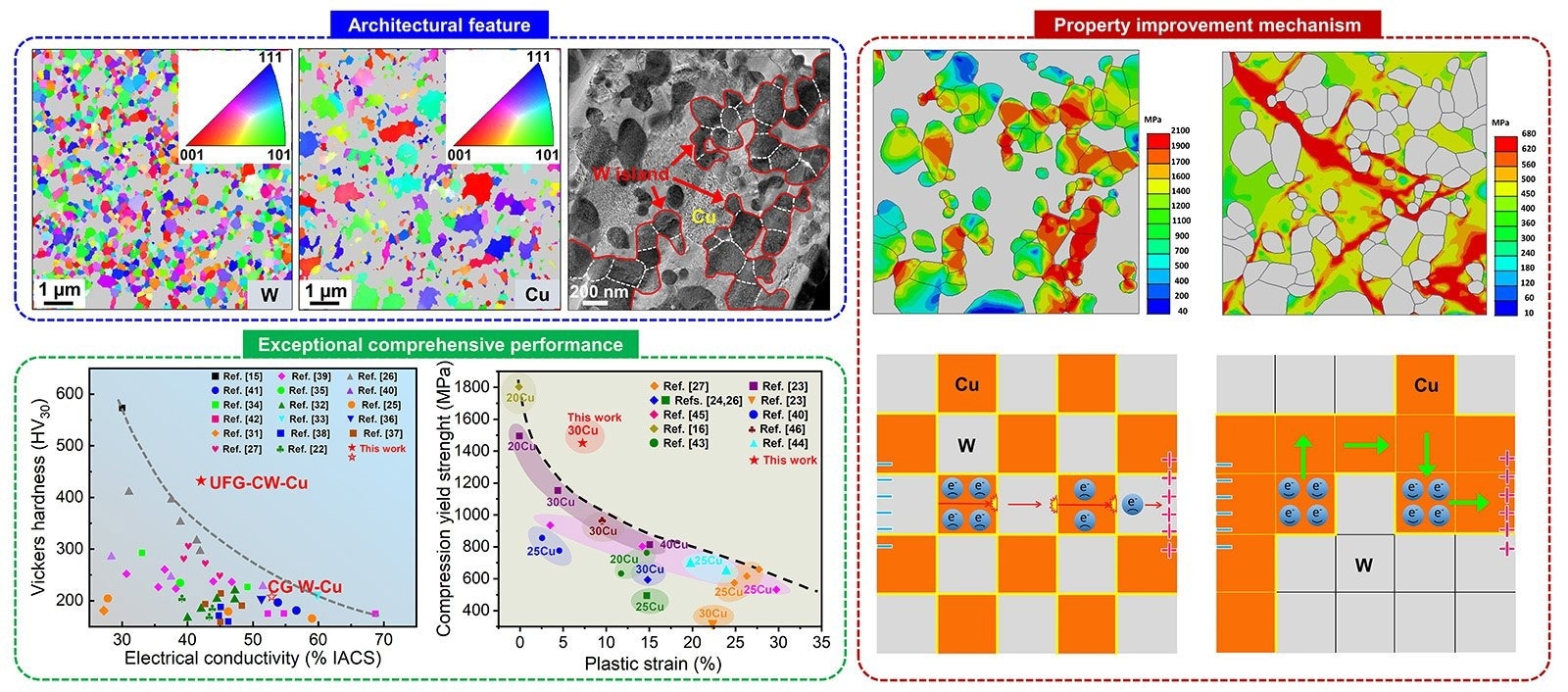

Development of a novel immiscible bimetal. Architectural feature, exceptional comprehensive properties, stress distribution analysis, and diagram of electron transport path for the developed novel bimetallic composites. Image Credit: Frontiers Journals

Development of a novel immiscible bimetal. Architectural feature, exceptional comprehensive properties, stress distribution analysis, and diagram of electron transport path for the developed novel bimetallic composites. Image Credit: Frontiers Journals

Immiscible bimetal materials exhibit distinctive combined mechanical and physical properties arising from the markedly different characteristics of their constituent metals. W–Cu bimetal composites are a common example of immiscible bimetallic systems.

They are used extensively in electronic packaging, heat sinks, high-voltage electric contact parts, and welding electrodes because of their high hardness, low thermal expansion coefficient of W, and good electrical and thermal conductivities of Cu.

Developing advanced bimetal composites strongly demands excellent integrated properties, such as high mechanical properties and electrical conductivity.

The team developed a novel W–Cu bimetal composite with exceptional mechanical properties and electrical conductivity to address these challenges. This novel composite is an ultrafine-grained W–Cu bimetal with specific W islands comprising an aggregation of ultrafine W grains and spatially connected Cu. Rapid low-temperature sintering and a carefully planned powder pretreatment process produced the distinctive microstructure.

The current bimetal demonstrated remarkable comprehensive properties, such as high yield strength, large plastic strain, and excellent electrical conductivity, compared to other W–Cu composites documented in the literature.

The stress distribution, strain response of each phase, and fracture behavior of the current bimetal were quantitatively examined using a finite-element simulation based on the actual microstructure of the experimental materials. The simulation showed that the stress distribution in each phase is significantly influenced by the proximity of fine W grains.

Higher W grain contiguity is better at preventing long-range stress extension and stress increase in the Cu phase under the same load. Therefore, the homogeneously distributed W phase among Cu may not be as stressed in the conventional W- Cu bimetal as in the specific W islands containing contacted ultrafine W grains.

Consequently, the high yield strength results from both the microstructure refinement of bimetal and the high grain contiguity in W islands.

Moreover, at the W/Cu phase boundaries, the coordinative plastic deformation of Cu and W islands can continue without failing too soon. Therefore, the special arrangement of the W islands and Cu phase makes it easier for both phases to deform simultaneously, increasing the W phase's contribution to the bimetal's overall plasticity and producing a composite with a good yield strength and plastic strain balance.

This bimetal has a high electrical conductivity because of the increased mean free path of Cu and the decreased proportion of phase boundaries brought on by the presence of W islands.

Additional Co-authors include Qixiang Duan, Chao Hou, Tielong Han, Yurong Li, Haibin Wang, Xiaoyan Song, and Zuoren Nie.

Journal Reference:

Duan, Q., et al. (2024) Synergistic Enhancement of Mechanical Properties and Electrical Conductivity of Immiscible Bimetal: A Case Study on W–Cu. Engineering. doi.org/10.1016/j.eng.2024.07.024.