Reviewed by Lexie CornerFeb 18 2025

A research team from Boston University reported the development of a droplet microfluidic component library in a study published in Microsystems & Nanoengineering. The study introduces a rapid and cost-effective method for fabricating microfluidic devices, which is important for expanding access to high-throughput chemical and biological screening.

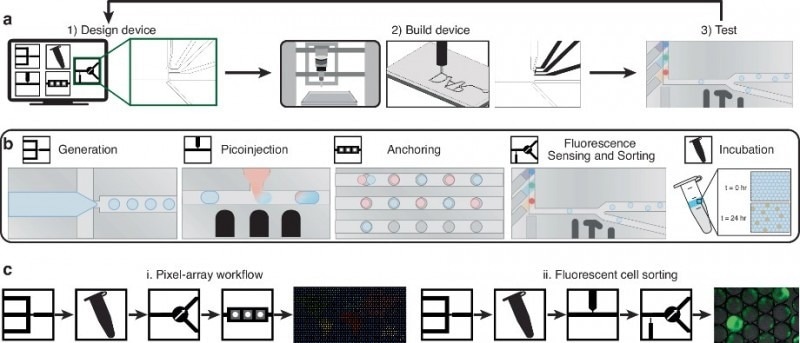

Overview of fabrication techniques and component library. a Design, build, test cycle for droplet microfluidics. b Droplet component library including droplet generation, anchoring, incubation, picoinjection, and fluorescence sorting. c Example droplet microfluidic workflows. Droplets are generated, reinjected, sensed, sorted, and anchored in a pixel array. Additionally, droplets with cells are generated, reinjected, picoinjected, sensed, and sorted for fluorescent cell sorting workflow. Image Credit: Microsystems & Nanoengineering

Overview of fabrication techniques and component library. a Design, build, test cycle for droplet microfluidics. b Droplet component library including droplet generation, anchoring, incubation, picoinjection, and fluorescence sorting. c Example droplet microfluidic workflows. Droplets are generated, reinjected, sensed, sorted, and anchored in a pixel array. Additionally, droplets with cells are generated, reinjected, picoinjected, sensed, and sorted for fluorescent cell sorting workflow. Image Credit: Microsystems & Nanoengineering

Droplet-based microfluidic systems have applications in protein engineering, single-cell sequencing, and nanoparticle synthesis. However, conventional fabrication methods, such as those using polydimethylsiloxane (PDMS), are costly and time-intensive, often requiring cleanroom facilities or external vendors.

Alternative fabrication techniques, including 3D printing and laser cutting, have been explored, but they present limitations in scalability, material compatibility, and resolution. There is a need for a more efficient, cost-effective, and accessible approach to microfluidic device fabrication.

The newly developed droplet microfluidic component library utilizes conductive ink electrodes and a micromilling technique to produce microfluidic devices at a cost of less than $12 per unit, significantly reducing expenses compared to conventional methods. The design-build-test cycle can now be completed within a single day. The library includes components for sorting, anchoring, fluorescence sensing, reinjection, droplet generation, and picoinjection.

These devices are biocompatible and capable of performing complex tasks such as pixel array formation and fluorescent cell sorting. A key feature of the library is its ability to generate visual "signatures" that verify droplet processing accuracy, providing a diagnostic tool for quality control and troubleshooting in multistep workflows.

This new automation-focused approach for fabricating droplet microfluidic devices is a significant advancement. By drastically reducing both the cost and time required for device production, we can now rapidly prototype and test new designs in standardized ways amenable to computer-aided design. This opens up numerous possibilities for high-throughput applications in biological and chemical research, making sophisticated microfluidic technology more accessible to a broader range of scientists and engineers.

Dr. Douglas Densmore, Study Co-Author, Boston University

This microfluidic component library has broad applications. The technology enables rapid iteration and testing of initial designs, reducing the time and cost associated with device fabrication. This approach is particularly useful for generating large datasets, which are essential for improving computer-aided design (CAD) tools for microfluidics.

The ability to generate and analyze complex droplet arrays could enhance chemical and biological analyses, with potential applications in genetic circuit analysis and protein engineering. This advancement contributes to the continued development of microfluidic technology.

Journal Reference:

McIntyre, D., et al. (2025) Component library creation and pixel array generation with micromilled droplet microfluidics. Microsystems & Nanoengineering. doi.org/10.1038/s41378-024-00839-6