Performance is the key parameter that determines the standard of a product in the sport and leisure industry. Testing provides an in-depth insight into product performance, allowing the engineers to easily determine the material suitability and the integrity of manufacturing processes according to quality control initiatives.

In addition, component testing plays a vital role in product engineering with the continuous development in the role of technology and sports equipment manufacture. Companies such as Oakley, Nitro Snowboards and Alpinestars test the mechanical properties of their sports equipment using Zwick testing machines.

Oakley

Oakley is a world-renowned sports eyewear and apparel manufacturer that combines high performance with excellent design. Using a distinct design approach, the company converts the functional demands of each sport into high quality products that offer excellent security along with visual appeal.

Oakley uses new molding techniques to optimize the curvature and stiffness of the lens based on the specific application. The company has its testing laboratory in Foothills Ranch, California where different properties have been assessed to design new products.

Some of the properties explored in this laboratory according to Oakley’s Vision Performance Testing Manager, Wayne Chumbley include compressive strength and impact resistance.

In accordance with the specific sport application, Oakley is involved in the manufacture of goggles for motocross applications, which is free of problems like lens collapse, lens ejection and lens penetration.

The motocross lenses are manufactured with specific thickness and molded arc that impart both safety and visual acuity as per ANSI and the U.S. military standards.

Figure 1. Goggles for motocross applications

According to ANSI Z87 standards, the testing procedures need to quantify high velocity impact resistance. The procedures involve shooting a quarter-inch steel ball at the lens and frame at a rate of 250ft/s from below 10in distance.

The U.S. military standard MIL-PRF 31013, however, prescribes the use of an irregularly-shaped projectile to closely simulate operational conditions. The projectile is shot at a rate of 650ft/s at the lens, which is substantially higher than the velocity prescribed by the ANSI standard.

Oakley also utilizes a compression testing procedure that quantifies the force required to cause the lens to impact the rider’s face. Zwick’s testXpert II measurement and control software offers a comparison of results for the Oakley Mayhem Pro goggle with a competing product.

Further, the company carries out a compression testing procedure to quantify the force of the lens at which it impacts the rider’s face. Using the Zwick’s testXpert II measurement and control software, the results of the Oakley Mayhem Pro goggle with a competing product are compared.

Besides evaluating the compressive strength of the lens, the compression test also evaluate the performance of the lens and chassis together. Chumbley, after reviewing the resulting data in the testXpert II software, confirmed that the strength of Oakley Mayhem Pro goggle is twice more than that of the competing product.

Nitro Snowboards

Established in various locations from Chile in the southern hemisphere to some of the most challenging mountains in Europe, Nitro Snowboards is the manufacturer of snowboards that are field tested year round.

Snowboarding is a sport that continues to change as riders explore new horizons. To meet the requirements of these new explorations, the boards are designed by introducing new materials using high-tech engineering methodologies.

New combinations of composite materials including glass and carbon fiber are introduced to the primary element – wood so as to offer better handling and greater stability.

Further, with the development of new riding methods such as high speed, powder, and new forms of freestyle, the materials and the shape of the boards have been modified. The availability of new manufacturing processes is another critical factor that contributes to the level of engineering involved in commercializing new snowboards.

The quality of the ride is a function of the board’s ability to move and respond in the direction of the rider. The testing procedures can be used for assessing the control and response. Nitro’s products offer optimizedtorsional flexure and flexural strength which are tested using a Zwick Allround-Line test machine.

The flex and shape properties of snowboards are tested using a 3-point flexure test. The test involves loading the board up to a break point in a special flexure test kit. It can also be used to assess current production batches.

Besides, snowboards, Nitro also carries out tests on bindings, boots and boot laces. Other areas of interest include peel tests on composite materials and fabric tear tests. According to Florian Lang, Head Developer at Nitro, the testXpert II software is used for assessing the design cycle and quality control programs.

Figure 2. Nitro2

Alpinestars

The MotoGP Championship, a world road racing championship requires the drivers to take turns at highest speeds without losing control of the bike in the race. This practice in turn requires suitable gear and apparel that can perform at highest levels without any error.

Alpinestars started as a footwear manufacturer for motorcycle racing. Following this, the company expanded its services with the manufacture of protective gear and apparel in motorsports. Leather is a primary material used in most of the Alpinestars’ products.

The suitability of different types of leather needs to be assessed due to the fact that tanning treatment may have a major impact on material properties. Compression and tear strength tests, tensile test, abrasion tests and UV exposure tests are the assessments carried out in company’s development laboratory in northern Italy. A Zwick testing machine is used to carry out compression testson boots according to the EN13634 standards.

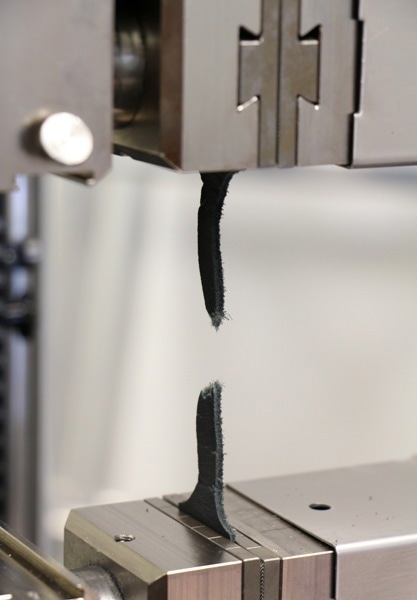

Leather grades that are added with brightly colored pigments exhibit reduced strength as the fibers tend to weaken over the time. Alpinestars carries out tensile and tear strength tests on all leather grades and fabrics used in finished products.

Figure 3. Leather used by Alpinestars

Material testing serves as a vital element in the development of sporting apparel, gear and protective wear by offering various insights according to specific applications.

About Zwick GmbH & Co. KG

Zwick is one of the top-ranking manufacturers of static and dynamic materials testing systems worldwide. With our extensive portfolio of testing machines, systems, and software we supply customized solutions for almost all test tasks required in the area of modern mechanical materials testing.

This information has been sourced, reviewed and adapted from materials provided by ZwickRoell GmbH Co. KG.

For more information on this source, please visit ZwickRoell GmbH Co. KG.