Many different industries use optical profilers for precision 3D measurements. This article provides the comparison of ZDot™ optical profiling technology, a patented solution from KLA, against white light interferometry (WLI).

White Light Interferometry

WLI can measure surface heights ranging from millimeters down to nanometers. The vertical resolution of WLI is not dependent on the field of view or magnification, making it suitable for applications with low topographic features on smooth, flat surfaces. However, for 3D optical profiling of complex surfaces with a wide variety of topographic features, WLI has its own drawbacks:

- More sensitive to vibration and sample tilt

- The optical system’s low light throughput design limits WLI imaging capability

- Not capable of handling samples with transparent and multiple layers, large height or large reflectivity variations, high roughness, and low reflectivity

ZDotTM Optical Profiling Technology

The drawbacks found in WLI can be overcome with ZDot™ optical profiling technology, which has an optical design that is inherently insensitive to vibration and sample tilt and has high light throughput. As a result, ZDot™ optical profiling technology provides unprecedented metrology capability for challenging R&D and manufacturing applications, including microfluidics, solar cells, advanced semiconductor packaging, and high brightness LED.

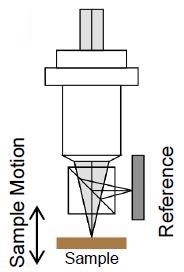

High optical efficiency and light throughput are critical requirements for profiling surfaces consisting of low reflectivity or high aspect ratio features, including vias or deep trenches. The optical design of WLI- based optical profilers limits their light throughput, as shown in Figure 1.

Figure 1. Michelson interferometer

Splitting of the illuminating light between the reference mirror and the sample limits the light available for imaging. When the illuminating light is split into separate optical paths, a relative motion is created between the reference mirror and the sample even by low levels of vibration. This, in turn, lowers vertical measurement resolution significantly. In addition, the vertical resolution of interferometers is further reduced due to the narrowing of interference fringes caused by sample tilt.

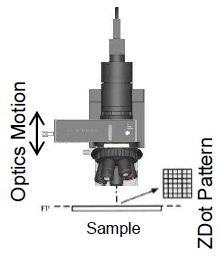

These limitations are overcome by Zeta-20 Optical Profiler featuring ZDot™ technology with its unique design. In Zeta-20 Optical Profilers, a common optical path is used for both focusing and imaging, as shown in Figure 2. ZDot™ generates contrast irrespective of the sample using a confocal grid structured array illumination (CGSI). This, in turn, allows Zeta-20 Optical Profiler to perform z-height measurements on virtually all surfaces. With its unique optical design, Zeta-20 Optical Profilers become inherently immune to vibration and sample tilt.

Figure 2. Zeta-20 Optical Profiler

The following table compares the WLI and the ZDot™ technologies:

| |

ZDot™ |

WLI |

| Imaging |

True Color |

False Color |

| Cost |

Standard Objectives |

Specialty Objectives |

| Operationmodes |

ZDot™, Interferencecontrast, Interferometer, Film Spectrometer, Scribe, Dark Field, Through Transmissive |

WLI only |

Customer Testimonial

We tried using our interferometer to profile an important transparent sample with low-contrast topography, but were unable to focus. With the Zeta-20 Optical Profiler, we were able to completely characterize the sample in a few minutes.

Dr. Antonio J. López,King Juan Carlos University, Móstoles, Spain

Applications of ZDot™ Technology

ZDot™ technology can be used in the following applications, where WLI fails to deliver:

- Solar substrates and devices - ZDot™ technology is capable of handling dissimilar materials in the same field of view, showing true film colors.

- LED processing – Repeating patterns pose a challenge to WLIs, whereas patterned substrates can be effectively characterized with ZDot™ technology.

- Surfaces with high slope – WLI cannot image surfaces with high slope, but ZDot™ technology can do.

- Microfluidic devices – WLI cannot image buried layers with transparent surfaces, but ZDot™ technology can do.

Accessories

The following accessories are offered along with the Zeta-20 Optical Profiler:

- Diamond Scribe to mark defects

- External dark field illumination

- Edge Inspection Fixture with dark field illumination

- Through Transmissive illumination

- SWIVEL Head option

Conclusion

With ZDot™ optical profiling technology, the concept of confocal microscopy is extended with the additional benefit of true-color imaging. In addition, imaging complex surfaces can be performed without any difficulty. These capabilities make the ZDot™ optical profiling technology suitable for challenging R&D and manufacturing purposes.

This information has been sourced, reviewed and adapted from materials provided by KLA Corporation.

For more information on this source, please visit KLA Corporation.