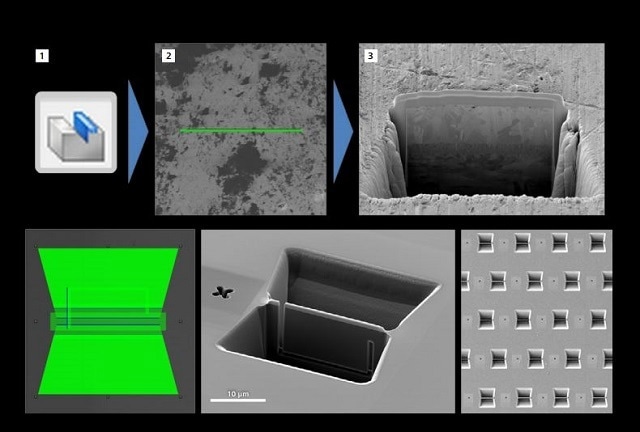

SmartFIB is a new user interface for focused ion beam (FIB) operation in ZEISS Crossbeam instruments. The user interface and some of it's capabilities are outlined in this article. SmartSEM is the operating software of ZEISS scanning electron microscopes (SEMs), and is compatible with ZEISS FIB-SEM instruments. SmartFIB is an extension of this operating software, and has been designed to support all workflows of FIB-SEM in an intuitive and easy manner.

Introduction

ZEISS launched two new FIB-SEM systems in late August 2013. These instruments, called ZEISS Crossbeam 340 and 540, were integrated with several key technological advancements, including a fully refurbished system platform with the latest electronics, a fully redesigned FIB user interface (UI), and a high throughput 100 nA Ga+ FIB column.

As mentioned above, the FIB UI is an extension of SmartSEM utilized for FIB control in ZEISS Crossbeam systems. As a result, this interface only becomes operational and active on FIB-SEM systems. In the following section it will be referred to as SmartFIB for convenience. The article describes the key features of SmartFIB and how it enables users’ day-to-day FIBSEM activity.

Areas Discussed

- Milling strategy

- Live imaging

- FIB pattering

- Advanced nudge control

- Automatic sample prep

- Sample mode

- Serial section imaging

- Interfacing with Smart FIB

This article has provided a brief overview of the SmartFIB user interface. Using SmartFIB, flexibly milling strategies can be customized to acquire the most optimum result on almost any possible pattern. The combination of sophisticated nudge control and live milling enables user’s intervention and interaction during the milling process. Users can easily set up TEM samples and cross sections for automatic preparation following a streamlined three-step workflow. In addition, the sample mode of the SmartFIB helps to expose layout batches that have been unattended for a prolonged period of time. Serial Section Imaging is another unique, automated workflow for FIB-SEM that provides the maximum amount of data from the VOI.

This information has been sourced, reviewed and adapted from materials provided by Carl Zeiss Microscopy GmbH.

For more information on this source, please visit Carl Zeiss Microscopy GmbH.