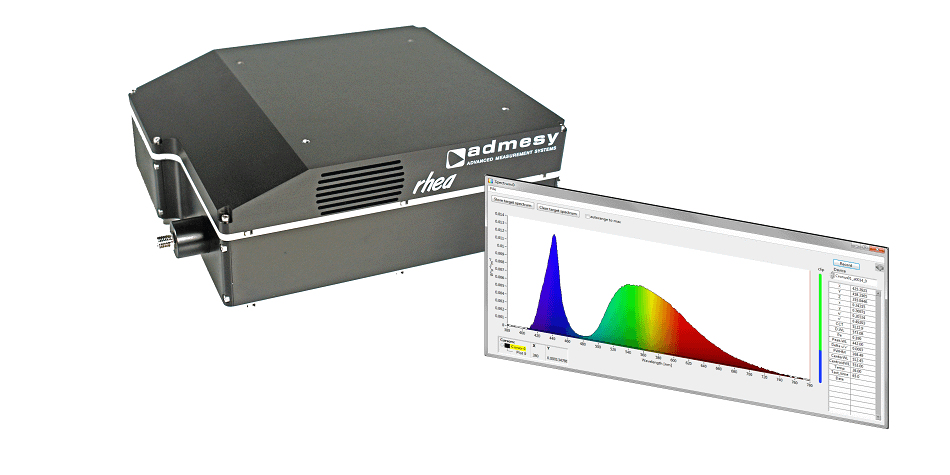

The Rhea is a high-end spectroscopy platform that has been specifically designed with OEMs in mind. The spectrometer can be fine tuned for different applications by focusing on specific areas of the spectrum and uses a novel internal calibration method to give highly accurate results. In addition to this the Rhea's competitive price opens up spectroscopy to a whole world of new applications.

AZoM spoke to Jeffrey-Alexander Lemmens, of Admesy, about the Rhea, the technology that makes it tick and the problem solving approach that Admesy take with OEMs.

What features of the Rhea spectrometer platform make it an attractive option for OEMs?

I’d say the most interesting and attractive feature of the Rhea, from an OEM’s standpoint, is the flexibility of the instrument.

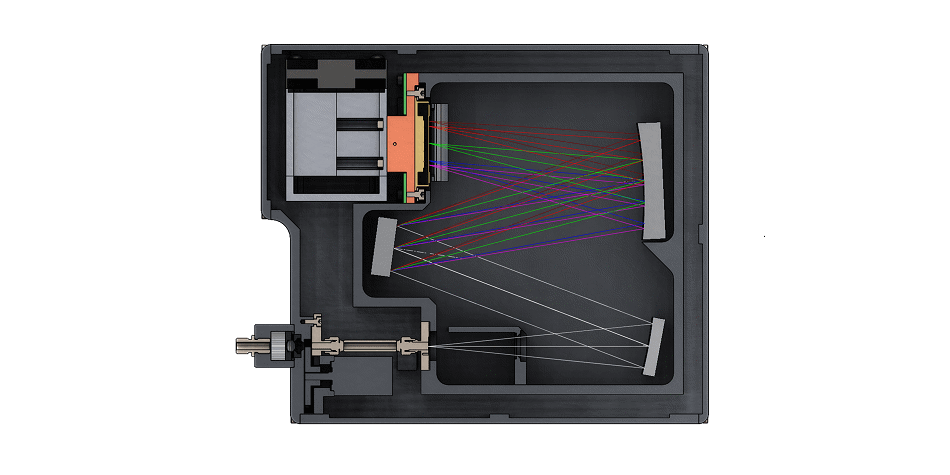

The Rhea has a completely customisable spectral engine. Our customers can choose the slit size – which, by itself is not that exciting. However, they can also choose the grating, to select a specific wavelength range; allowing the instrument to be focused on a specific spectral region. There is also a choice between two different sensors.

By fine tuning these different parameters you can build a custom spectrometer for your specific measurement needs in the range of 200 to 1,100 nm.

In addition to the customisability the Rhea has many other interesting features characteristic of high-performance spectrometers such as a cooled CCD sensor, a high sensitivity and a high dynamic range. All of these factors combine to give an extremely precise and accurate spectral engine.

The Rhea Spectroscopy Platform. Image Credit: Admesy

Which industries do you expect to benefit from the Rhea the most?

Due to the high versatility and customisable nature of the Rhea we don’t expect any specific industry to benefit from this – we don’t even have a list of target industries. We expect any industry that requires accurate spectral measurements to benefit.

For example, this could be a filter manufacturer who requires accurate spectral transmission data or it could be an OEM who wants to produce a robust and precise gas analysis machine.

By creating a high-end spectrometer at an accessible price we’re hoping to see more and more application fields open up. Currently affordable spectrometers tend to give poor results which means they can’t be used in applications which require a high sensitivity; however, the required ‘high-end’ spectrometers are often too expensive to be used.

We expect the Rhea to be popular with all of the known application areas that high-end spectrometers cater for, such as chemical analysis and lighting/display research and quality control, but we also expect the Rhea to be used in many application areas which haven’t used spectroscopy in the past as it was too expensive.

We’re looking forward to seeing what brilliant ideas our customers use the Rhea for!

How easy is it to integrate the Rhea with existing systems?

Integrating the Rhea with other systems is easy. Admesy design all of our systems so that integration with other systems is as simple as possible.

When it comes to hardware the Rhea has several different methods of communication through several different ports including Ethernet, USB, RS232 and trigger in and out ports. All of these modes of communication mean that the Rhea can effortlessly communicate with other hardware present on a production line.

On the software side of things, the data readout has been designed to work with a variety of platforms including LabView, Visual Studio, C#, CVI and LabWindows.

However, specifics aside, I think one of the most important features of the Rhea is that our customers do not need to worry about calibrating the device. The Rhea is a plug and play device - ready to work as soon as it is unpacked from the box.

This is in contrast to most high-end spectrometers in the market which often require customers to adjust many settings, change the devices parameters and calibrate before they can actually make any measurements.

What this means in practice is that the customer can focus solely on their analysis. They don’t need to worry about the specifics of how the spectrometer works or have to consult an expert on the best way to calibrate their spectrometer – it’s already been done for them.

As all of the calibration is built in there is also no chance of an erroneous calibration; which can result in questionable results a few months down the line – and a big headache when trying to troubleshoot what the problem might be.

The Rhea's spectral engine is entirely customised - the slit size, grating and sensor type can all be tweaked to focus on application-specific spectral regions. Image Credit: Admesy

Can the Rhea be tailored to communicate with other technologies as part of a combined instrument?

Yes, absolutely. The hardware and software features we discussed earlier mean it is just as easy for the Rhea to communicate with existing systems as it is for the Rhea to be part of a new system.

By using a set of standard commands and physical trigger in & out ports, the Rhea can be triggered to measure at exactly the right time in an instrument. For USB for example it is USB TMC compatible. On the hardware side, we support the widely used SMA fiber connectors as well as our M8 fixed position fiber and fixed optics.

What is the Rhea’s detection range? Can it be fine-tuned for specific applications?

The Rhea can cover a broad range from 200 nm up to 1,100 nm. Additionally, if you are interested in a specific range within that spectrum we can ‘zoom in’ and focus on that range – optimising the response in the desired wavelength range.

It’s important to stress here that with spectrometers there tends to be a compromise between the range of the spectrometer and its relative sensitivity. This means that broad spectrometers (with a range of 200 – 1,100 nm) typically are much more sensitive in the middle of this spectrum with a drop in sensitivity on the outer ranges.

This would be problematic for customers who are interested in the outer limits of the range such as companies which require the accurate measurement of NIR blocking filters. With the Rhea we can now support these customers’ demands by providing a highly sensitive spectrometer with a spectral range of 800 – 1,100 nm.

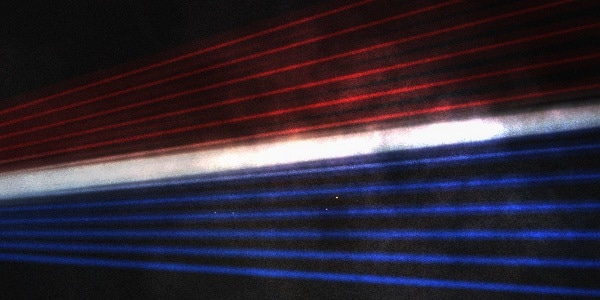

Does the ability to select wavelength ranges make the Rhea suitable for Raman spectroscopy?

Yes of course, it’s not only suitable – its excellent. Using the correct grating, sensor and slit combination, which we’re more than happy to help our customers with, provides an ideal Raman spectrometer.

Depending on its configuration the Rhea has the potential to be used for specialised spectroscopic techniques such as Raman spectroscopy

How does the Rhea ensure that its measurements are of high accuracy?

The Rhea is highly accurate for two main reasons which are the internal calibration that takes place when measurements are made, and also the extremely high-performance build quality of the machine itself.

There are multiple different ways to carry out calibration on dark noise to make sure that the spectrometer gives a linear response. The Rhea uses a different method from our competitor’s spectrometers which has been demonstrated to give more accurate results. In addition to this the instrument also carries out wavelength calibration to ensure extremely accurate results.

The instrument itself is built using high quality parts. The highly accurate sensor has an optimised lifespan and the other key components are all high-specification. We want a build quality that means that any two spectrometers that we produce will give identical results. As our manufacturing process is so strict we are confident that the end result gives the maximum accuracy possible.

What level of customisation does Admesy deliver for OEMs?

We can offer a lot of customisation. As we discussed earlier the spectral range of the spectrometer can be fined tuned with custom slits, gratings and sensors. For OEMs, who want to use the Rhea spectroscopy platform in an instrument we offer several options.

For OEMs who want to produce a ‘simple’ spectrometer they can use the plug and play version of the Rhea, by the USB or Ethernet cable, which is easy to use. All the OEM would have to do is build their product around the frame of the Rhea and they would have their device.

For more complex systems we can lift out the spectral engine of the Rhea and build it into a new device whilst removing any components or features which are unnecessary. We welcome the opportunity to sit around the drawing board with OEMs and determine the best way to integrate the Rhea into their systems.

Rhea Spectrometer uncovered

Where can our readers find out more about the Rhea and Admesy?

The best place to go to find out more would be our website.

We’re also going to be exhibiting at Photonics West, which runs between the 31st of January and the 2nd of February in San Fransico. We’re hosting a booth in the South Hall, you’re welcome to drop by booth #2713 and we can talk about the Rhea in more detail.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.