Mid-IR chemical imaging is an established quantitative technique that combines the benefits of infrared spectroscopy and microscopy to provide snapshots of a sample’s chemical composition and distribution.

Basing the technology on Quantum Cascade Lasers (QCLs) has resulted in revolutionary improvements to this technique, which have been pioneered by Daylight Solution's Spero® platform, which allows high-resolution chemical imaging of cells and polymers to be carried out effortlessly. The technology is now being pushed further by the introduction of the new Spero-QT, which is even faster and more powerful; opening up new applications such as whole organ imaging, intraoperative surgical digital pathology and the analysis of pharmaceutical powders, tablets, and polymer composites.

AZoM spoke to Dr. Jeremy Rowlette, Director of Molecular Imaging at Daylight Solutions, about the Spero-QT, the new application areas the advanced technology will open up and the many benefits it will deliver to researchers.

What makes mid-IR infrared imaging such a powerful technique?

Mid-infrared (mid-IR) imaging is a ‘label-free’ spectroscopic imaging technique that lets you “see” the native chemistry within your sample. Hence, we often use the term chemical imaging interchangeably.

Almost all biological and organic materials such as polymers are made of molecules which have natural vibrations that can be excited by mid-IR light, the radiation band including the range 5,000-11,000 nm. Unlike UV (200-400 nm), visible (450-650 nm) and near-infrared (800-2000 nm) spectroscopy techniques, mid-IR spectroscopy can be used to distinguish between compounds with a very high specificity because each molecule has a unique spectral fingerprint.

Mid-IR imaging is an extension of Mid-IR spectroscopy. Instead of giving a single average spectrum over a large portion of a sample that the Mid-IR beam passes through, as in a spectrometer, a Mid-IR imager generates independent spectra for many (hundreds of thousands to millions) tiny segments of the sample falling within the microscope’s field-of-view (FOV).

Mid-IR imaging can be used, for example, to distinguish between healthy and diseased tissue or between two types of active pharmaceutical ingredients (APIs) or blended polymers quite easily and without ambiguity based purely on their chemical vibrational signature. It can also be used to identify regions of interest in cells, or to identify chemical distributions in mixtures of dry and pressed powders.

Because the technique probes the intrinsic vibrational signature, no fluorescent tags, stains, or labels are necessary so the technique can be fast and non-invasive. This is important for many applications, especially when the full chemical profile of the specimen is needed for archiving or to ensure success in downstream sampling by gene sequencing and proteomic analyses.

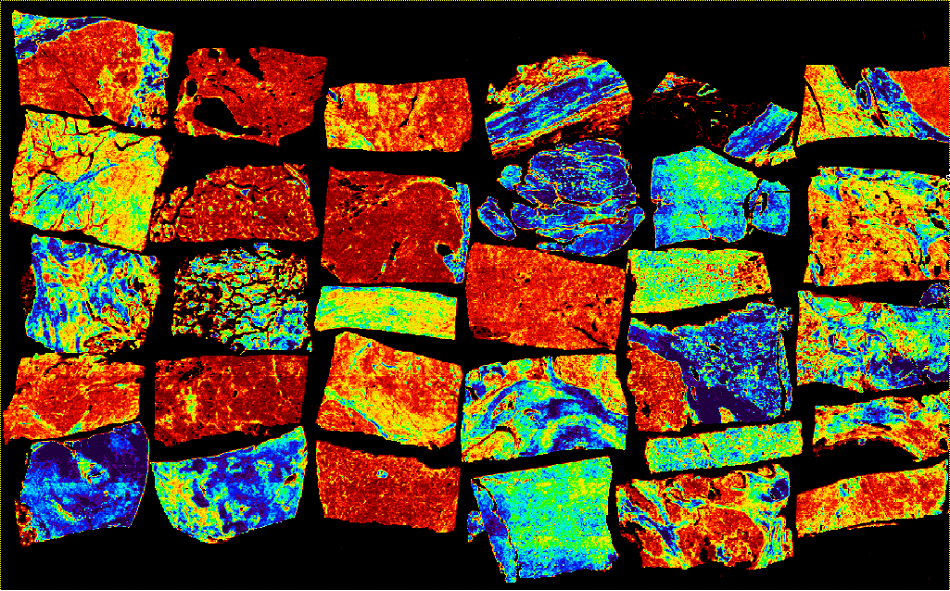

A tissue micro-array imaged in the mid-infrared region using the Spero-QT

What are the key differences between the first and second generation Spero?

The Spero-QT builds upon the significant technological leaps made in the first generation platform released in 2014, which remains the only commercially available wide-field microscope based on quantum cascade laser (QCL) technology.

With feedback from dozens of users in 9 countries, we have learned how to make the instrument even faster, more compact, and easier to use.

Ease-of-use for our customers is very important to us at Daylight, which is why we have eliminated cryogenic cooling and invested heavily in software development to streamline sample navigation and data collection. Even though many of our users are experts at spectroscopy and in some cases have even built table-top versions of laser microscopes, our mission is to enable these researchers operating on the cutting edge of cancer research and drug development to focus their efforts on making breakthroughs in their applications and not have them worry about the instrument.

What motivated the team at Daylight Solutions to further enhance the Spero?

Our customers.

Our loyal customers rightfully demand a vibrant and innovative technology roadmap and they have come to expect one from Daylight Solutions.

We have been serving the academic and industrial research market for over 12 years now and currently have more than 700 high-precision scientific instruments in the field. We attribute this success in large measure to our reputation for always striving to meet the demanding technological challenges posed by our customers. We will continue this pursuit with passion and the Spero-QT represents another major step forward.

The Spero-QT from Daylight Solutions

Does the increased spectral resolution data acquisition speed of the second generation Spero allow it to be used for new applications?

The Spero-QT in its highest performance configuration is 20 times faster than the first generation microscope. 230,400 spectra, each containing 450 spectral data points, can now be collected in about 35 seconds at a noise level of about 1 mAU. At this speed, whole-slide, label-free chemical imaging will become routine.

The second big advantage of increased speed is that more scans can be collected in the same period of time enabling higher sensitivity measurements. This is opening up new applications such as wide-field diffuse and specular reflectance imaging of tablets and powders.

Where can you see powder analysis being practically used? Is any other technology capable of this?

Powders are used extensively throughout the pharmaceutical industry as active and inactive ingredients in, for example, the formation of tablets.

For quality control, it is becoming increasingly important to quantify not just the relative ratios of ingredients within tablets but also their spatial distribution. In every batch, some tablets are randomly selected, cross-sectioned and spectroscopically analyzed to resolve the concentration and spatial distribution of the active pharmaceutical ingredient (API) relative to the inactive matrix.

There are several techniques currently serving this application including UV-Vis, Near-IR and more recently Raman spectroscopy. With great investment, these techniques can be effective but can be relatively slow or suffer from poor specificity. For UV-Vis and Near-IR spectroscopy, achieving specificity is a significant challenge because of ambiguity in spectral band assignments. Raman bands are much easier to assign but the technique requires lengthy acquisitions to overcome the inherently weak signal levels and it can also suffer from a strong and varying auto-fluorescence background that undermine quantitative analyses.

Because of these limitations, these techniques are mostly performed downstream and offline by highly skilled personnel. Consequently, the data from these measurements have less of an impact on critical real-time decision making within the factory.

Leading scientists working to develop process analytical technologies (PAT) are beginning to recognize that there could be significant changes in the factory workflow if the throughput of such techniques could be enhanced by 2 or more orders of magnitude while also increasing specificity. Because of its throughput and signal-to-noise (SNR) advantages, the Spero-QT is beginning to answer this call in a variety of PAT applications, including non-contact, inline inspection of powders and polymer composites. Live, video rate imaging using a small number of mid-IR wavelengths tuned to API peaks is a game changer for this application.

How do you expect the enhanced features of the second generation Spero to benefit the tissue analysis applications that the Spero is used for?

Tissue analysis in pre-clinical and biomedical research remains the top application for the Spero microscope and nowhere else is the speed advantage more enabling. Three applications are being enabled by the 20x increase in spectral data acquisition speed.

The first is intra-operative, label-free digital pathology. Large (cm2) size biopsied tissues can now be analyzed at micron scale across the entire mid-IR fingerprint band and at full spectral resolution (450 spectral data points per 480x480 FOV for a total of 5.7 million spectra) in about 15 minutes. This is well within the 30 minute window typically allotted for intraoperative pathology consults and has the potential to inform surgical decisions for the first time.

The second is large (>1000) patient clinical studies that are aimed at improving the statistical robustness of mid-IR spectral libraries. As the libraries become more comprehensive and robust against population variation, we will see automated mid-IR screening become a more routine part of the workflow in pathology labs.

Finally, groups like the Petibois Group (U. Bordeaux, FR) are applying the speed advantage to new extremes by performing whole organ 3D chemical image reconstruction in small animal models to advance drug therapy development. Each organ can be cross-sectioned into hundreds of cm2 sized slices and imaged on the Spero-QT in just a few days. For comparison, using conventional infrared imaging technology, chemical image reconstruction of a single mouse organ would take about one year. With the speed advantage of the Spero-QT, leading pharmaceutical companies are leveraging this capability to routinely study both the positive and negative effects of drugs on multiple organ systems in early phases of drug development.

3D Histology with the Spero™ Infrared Microscope

How have Daylight Solutions’ engineers improved the Spero’s specifications whilst reducing the footprint?

We leveraged Daylight Solutions’ new MIRcat-QT laser source which is more than 50 times faster while also achieving superior wavelength and beam pointing repeatability.

The higher performance of the laser enabled our team to eliminate several optical components in the beam path and this allowed us to reduce the depth of the instrument by 100 mm. This may not seem like a lot but the footprint is now less than 2 feet in depth which allows it to fit on even the smallest of lab benches. For many of our customers, especially the biology and clinical researchers, bench space is an absolute premium. We are happy that we were able to deliver on this request.

How do you expect the second generation Spero’s larger scan area to benefit researchers?

In the Spero-QT, as many as 3 25x75 mm slides can be loaded and imaged at any time. Before, only a portion of a single slide was viewable without repositioning. Our customers working with large samples will see the biggest benefit from this improvement.

In addition to larger stage travel, the stages are linear motor actuated with 0.1 um closed-loop encoder precision. Over the entire range of travel, stitching repeatability and accuracy can now be brought below 1 um with proper calibration and environmental controls.

Finally, the entire sample compartment area has been opened up to improve accessibility. This is really important for our customers who are working with microfluidic devices or other accessories.

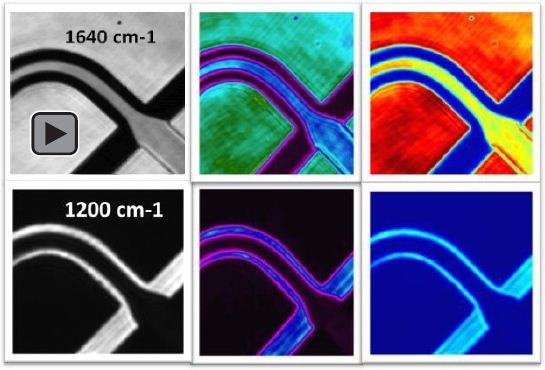

Infrared images of H2O and D2O flowing within a microfluidic channel.

What support do Daylight Solutions offer to customers who want to use Spero technology in novel experiments and applications?

No two customers use our Spero microscopes in exactly the same way. I would say that is really the nature of microscopy. And as makers of leading edge microscopy products, we fully appreciate how important it is to provide exceptional support before and after the microscope reaches the customer’s lab.

For Spero, we have a team of application scientists and instrument experts that will work with customers to develop their application. I personally handle all customer questions and am responsible for ensuring our customer’s get the best service possible. Each of my customers has my personal cell phone number and knows they can reach me almost anytime and anywhere.

Download the Brochure for More Information

Download the Brochure for More Information

About Dr. Jeremy Rowlette

Dr. Jeremy Rowlette is currently the Director of Molecular Imaging Products at Daylight Solutions and is a co-inventor of the Spero microscope.

Jeremy joined Daylight Solutions in 2010 as a senior member of the technical staff where he has since led the product development and market introduction of multiple quantum cascade laser technologies servicing defense, scientific and industrial research markets.

Dr. Rowlette received M.S. and Ph.D. degrees in Electrical Engineering from Stanford University in 2005 and 2010 respectively.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.