Interview conducted by Mychealla RiceNov 23 2017

Interview conducted by Mychealla RiceNov 23 2017In quality assurance, just as in research & development, reliable test results are the be all and end all. Not until accuracy, repeatability, reproducibility, and traceability all come together does testing fulfil its true purpose.

Johannes J. Bührle, Head of Industry Management at Zwick Roell, explains to AZoM how you can ensure that your tests meet these requirements and what problems can arise if they are not met.

Please tell us what ‘reliable test results’ mean to Zwick Roell?

At Zwick Roell, "reliable test results" is a term we use to address multiple questions at the same time.

The questions we address are:

- Is the value obtained from the test accurate?

- Are the results reproducible?

- Can the results be compared to other measurements?

- Is it possible to trace in detail the sequence of the test?

The test results are considered reliable only if all the questions are answered with a "yes".

Can you tell us why distinction is so important in materials testing?

Anyone who performs measurements and materials tests naturally has an interest in obtaining meaningful results.

Therefore, the first three points are important and comprehensible to everyone. The values obtained are not the end goal, but serve as a basis and way to verify the developments that lead to new materials and innovative products in the R&D department. In quality assurance, the results also provide information about product characteristics and can aid in process optimization.

The fourth point, traceability, provides assurance, even for third parties, that there is no denying the results.

By accurately documenting the test and its sequence of events, as well as the external factors/conditions, you can prove together with the test requirements that the tests were performed professionally.

This is the point at which systems are put in place to prevent falsification. Our products are designed to support the customer in the best way possible in these areas.

Robotic testing machines for full-automated tensile tests on metals. Image credit: ZwickRoell Gmbh Co. KG

Current events, such as Kobe Steel in Japan illustrate the backlog demand (untapped potential) in this area. Can you explain in more detail?

To start, I must say that you can only achieve 100% data integrity through a joint effort between testing equipment manufacturers and customers. Our goal is to support our customers during the system setup so that the falsification of test results can be reliably prevented with our four products and product families:

Our testXpert III testing software with Expanded Traceability, used by companies in the pharmaceutical industry, stores test data safely and protects it from falsification with an electronic signature. This test data covers the entire test sequence including all machine parameters. Flexible import/export functions that are adapted to the customer's primary quality management system by our IT experts ensure a smooth transfer of the protected data.

Then the customer comes into play: They must establish processes so that the data remains protected from falsification as soon as it leaves the secure area, for example through crosschecks using the double-check principle.

In addition to the comprehensive and reliable recording of the test data, a high degree of automation makes for high repeatability of the test results. The goal is to minimize any influences by the machine operator. Testing machines are mechanically equipped with adjustable stops, to ensure that specimens are always in the same position.

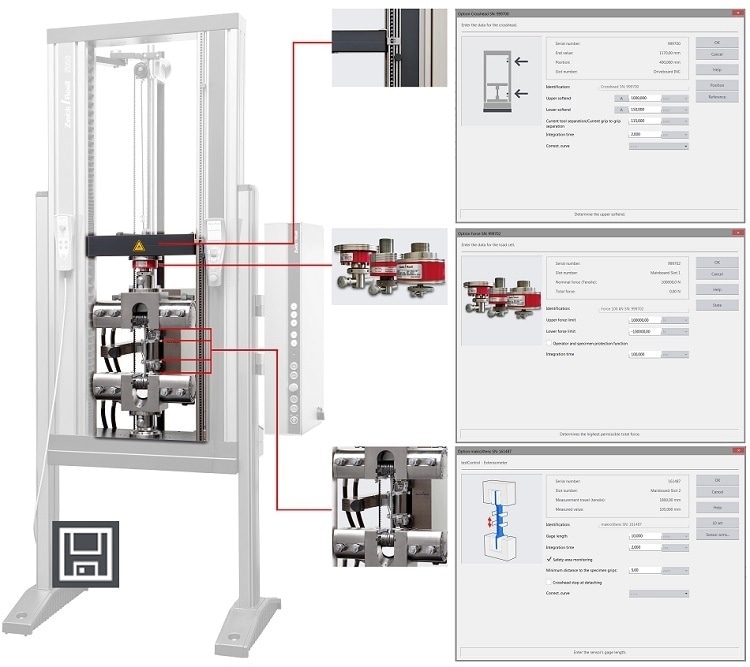

Furthermore, you can define the system configuration in detail in the testXpert III testing software to ensure that the distance between compression platens, specimen grips, and jaws are always the same and that soft limit switches are set accordingly, as well as the exact gripping pressure of the specimen grips is repeatable.

Those who want to take reliable test results to the next level will no undoubtedly discover robotic testing systems such as roboTest P and roboTest R, that perform large quantities on specimens fully automatically—always with the exact same handling.

Zwick Roell is researching new flexible solutions in this field. For instance, the Cobot system is still in the prototype stage and looks very promising. This is extremely easy to set up and the robot can work directly with people without you having to take any additional safety measures thanks to its advanced sensor technology.

The robot can be deployed quickly if necessary and learn its movement sequence from a coworker who will also support it in the short-term. At the same time, there is no risk of injury, if something gets in the way of the Cobot, it will immediately stop all movement. This system will revolutionize testing automation.

Short clamping hydraulic specimen grips. Image credit: ZwickRoell Gmbh Co. KG

Does that mean the way to achieve to reliable test results is via a combination of software and hardware solutions?

Yes, automated solutions reduce measurement errors and leave no room for human bias or intentional falsifications.

Therefore, in addition to assembling the testing machines as uniformly as possible, it makes sense to automate the test itself and the extension measurement.

Zwick has a whole range of various tactile and optical extensometers. These systems can even measure minimal strain values up to specimen break by using highly accurate sensor arms or cameras that transfer the values to the testXpert III testing software continuously.

Swiveling knife edges will prevent damage to the tactile sensor arms at specimen break. For the optical systems, the strain between two optically generated or marked points on the specimen surface is measured through multiple high-resolution cameras.

Of course, this can all be done as digital image correlation (DIC) with a dot pattern on the specimen surface in order to record two-dimensional movements and shifts.

Are there any new innovations pertaining to the theme of reliable test results?

In addition to the products already mentioned, our development of short clamping length hydraulic grips fit this topic well. The use of high-strength materials in several industrial sectors allows for designs and features that would have previously not been possible.

Of course, there is also a downside to new advancements; since the specimens must be made from manufactured components, often you cannot select the specimen size of your choice. The area at which the grip grips a small specimen is often very limited and at the same time, the required gripping forces for high-strength materials are extremely high.

This scenario can lead to normal specimen grip jaws no longer being parallel due to the reduced gripping area and in turn lead to the specimen slipping during tensile testing.

This effect leads to an invalid specimen or worse, falsifies the results. The newly developed, short clamping length specimen grips are designed to safely grab from the available area and keep the jaws parallel at the same time.

This prevents the specimen from slipping and allows you to obtain accurate test results. The combination of testing software, automation, and the specimen grips adapted to the application ensure reliable test results in the customer's quality management system.

testXpert III test environment concept. Image credit: ZwickRoell Gmbh Co. KG

What does this mean for the future?

Obtaining reliable test results is the goal of every materials test. They need to be accurate, repeatable, reproducible, and traceable to guarantee usability in any and all areas. Zwick Roell maintains a comprehensive portfolio of software and hardware solutions to reliably support its customers in this effort.

Where can our readers go to find out more?

To find out more please visit our website

About Johannes J. Bührle

Johannes J. Bührle is a degreed Engineer (Ulm University, Germany) & Executive MBA (IE Business School,Madrid & Fudan University, Shanghai.

Before he joined Zwick Roell, Johannes was an Automotive Industry Manager & Global Key-Account Manager at TRUMPF.

Since 2014, Johannes has been head of industry management at Zwick Roell.

This information has been sourced, reviewed and adapted from materials provided by ZwickRoell GmbH Co. KG.

For more information on this source, please visit ZwickRoell GmbH Co. KG

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.