Synthetic polyester fluids are formulated for use in aircraft gas turbine engines to deal with a vast range of extreme operating conditions. The factory supplied M/N program for compliance with the JOAP program uses D12 and D19 standards which are prepared from a mineral oil hydrocarbon base stock. The Spectroil analyzer provides the option to create a new calibration program with matrix-specific elemental standards for applications which require enhanced accuracy for non-mineral oil based fluids.

Introduction

Synthetic Polyol Ester fluids are the preferred fluids to lubricate aircraft gas turbine engines that are used in military and commercial service requiring MIL-PRF-23699F-STD level performance. These synthetic lubricants are also used for aircraft-type gas turbine engines in industrial or marine service applications.

These fluids are formulated to meet the challenging requirements of aircraft-type gas turbines operating over a vast range of extreme operating conditions. They have tremendous thermal and oxidation stability to bring down sludge and varnish deposits and they have a high specific heat. In addition, the lubricants preserve viscosity and film strength over an extensive temperature range (-40 °C to 204 °C or -40 °F to 400 °F).

When these fluids are tested on a Spectroil that has been calibrated with mineral based oil standards, there may be matrix effects accounted for in the sample. Such effects may not be accounted for in the commercially available mineral oil wear metal standards. A considerable difference in the sample matrix can alter the accuracy of the result although the trending capability of the calibration is maintained. A customized calibration program can be created by the user using custom or matrix-specific elemental standards for applications where accuracy is incredibly necessary or the matrix effect is severe.

Background

An analysis of the test standards (c0, c5, c10, and c20 of 0, 5, 10, and 20 ppm metal elements) and unknown samples of an in-service synthetic gas turbine lubricant on the Spectroil for wear metals was conducted. The synthetic oil type was MIL-PRF-23699F, NATO code o-156/o-152 which is a polyol ester based fluid. The samples and test standards were run using the factory Spectroil M/N program for compliance to the JOAP program using the mineral oil based D19 and D12 standards. For the JOAP mineral oil based standards D19-0 ppm, D12-5 ppm and D12-10 ppm, the instrument came up with accurate results but it did not provide satisfactory results for the synthetic test standards (Table 1).

Table 1. Data acquired for the JOAP M/N standards and the provided test standards.

| M/N PROGRAM |

| Sample |

Al |

Cr |

Cu |

Mg |

Ni |

Pb |

| D19-0 |

0.06 |

0.02 |

0.00 |

0.00 |

0.07 |

0.18 |

| D12-5 |

5.18 |

5.28 |

5.68 |

5.62 |

5.56 |

6.61 |

| D12-10 |

10.25 |

10.76 |

11.17 |

11.29 |

10.84 |

11.34 |

| c0 |

0.00 |

0.00 |

0.12 |

0.01 |

0.34 |

1.03 |

| c5 |

5.92 |

5.82 |

8.66 |

8.86 |

8.12 |

9.31 |

| c10 |

14.75 |

14.58 |

20.71 |

22.64 |

18.61 |

21.53 |

| c20 |

30.45 |

29.57 |

42.47 |

47.50 |

36.17 |

45.34 |

When compared to their known elemental concentration, the test standards reported significantly higher elemental concentration. From this, it was concluded that the poor accuracy was a result of the difference in matrix between the synthetic turbine oil compared to the mineral-based hydrocarbon JOAP standards. A new calibration can be created for improved accuracy.

Method

With the supplied test standards, a calibration could be created. However, an independent set of calibration standards was prepared with the same matrix oil for a more robust analysis. A set of synthetic turbine oil standards (SYNGT-0 ppm, SYNGT-50 ppm, etc.) was prepared by careful dilution of a D19-900 ppm oil standard into synthetic oil base o-156/o-152 at concentrations of 0, 5, 10, 20, 30, 50, and 100 ppm.

Figure 1. Creating a new calibration program using an existing program as a template.

A new calibration program SYNGT was developed by copying the existing M/N program on the Spectroil which is shown in Figure 1. The Standardization Sample Names SYNGT-0, SYNGT-5, SYNGT-10, SYNGT-20, SYNGT-30, SYNGT-50, and SYNGT-100 were added at the end of the list under System >> Standardization Samples which is shown in Figure 2.

Figure 2. Adding new standardization samples to a custom calibration program.

The procedure of calibration was then performed with the prepared standards in accordance with the standard operating instructions in the manual for daily operation.

- Three warm up burns

- Profile

- Disc offset procedure

- 5 burns of 0 ppm (o-156/o-152 oil) to set the reference values

- 5 burns of each prepared standard: 0 ppm, 5 ppm, 10 ppm, 20 ppm, 30 ppm, 50 ppm, 100 ppm.

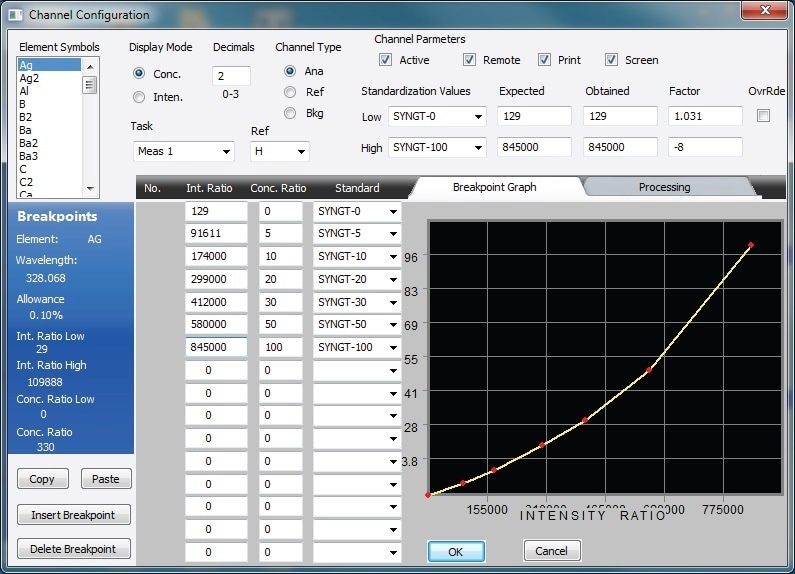

In Intensity Ratio mode, the results for five burns of each prepared standard were examined and then recorded. These values were entered as the calibration curves and the expected standardization values in the channel configuration screen in the SYNGT program for each element in the list, as shown in Figure 3. The fields with D-19 standards were replaced with the appropriate SYNGT standards. All other fields were left similar to the template M/N program. The channel configuration changes were saved by clicking ok.

Figure 3. Example calibration curve for Ag and the channel configuration screen.

Results

After the SYNGT program was set up and duly calibrated, the daily standardization routine was conducted and the standardization was confirmed with four burns of the SYNGT standards. The check burns made with the SYNGT standards were within the acceptable limits. The synthetic turbine oil test standards provided (c0, c5, c10, c20) were then analyzed using the SYNGT program. Table 2 shows the results.

Table 2. Example data acquired for the SYNGT standards and the provided test standards after calibration of the SYNGT program.

| SYNGT PROGRAM |

| Sample |

Al |

Cr |

Cu |

Mg |

Ni |

Pb |

| SYNGT-0 |

0.00 |

0.07 |

0.00 |

0.00 |

0.03 |

0.41 |

| SYNGT-5 |

5.19 |

5.08 |

5.08 |

5.30 |

5.08 |

5.82 |

| SYNGT-10 |

10.10 |

10.14 |

10.15 |

10.40 |

10.60 |

10.94 |

| SYNGT-20 |

21.11 |

20.59 |

19.98 |

21.08 |

20.95 |

21.32 |

| c0 |

0.02 |

0.00 |

0.00 |

0.00 |

0.01 |

0.00 |

| c5 |

4.73 |

4.46 |

4.72 |

4.52 |

4.92 |

4.09 |

| c10 |

11.36 |

11.30 |

11.56 |

11.41 |

12.01 |

11.15 |

| c20 |

23.69 |

22.62 |

21.92 |

23.28 |

23.15 |

25.78 |

The test standards were within an agreeable range of the known value (0, 5, 10, 20 ppm) using the new SYNGT program. Unknown turbine samples could now be analyzed with a certainty of the accuracy of the result.

Conclusion

When an elemental analysis is performed on the Spectroil, it is usually enough to use the appropriate factory-supplied program and elemental standards. Nevertheless, when accuracy is especially important over trending or for specific applications, it may be essential to develop a new calibration program with matrix-specific elemental standards. A customized calibration program can be readily generated using a current factory-supplied program as a template. The new calibration program can then be used to investigate samples with enhanced accuracy.

This information has been sourced, reviewed and adapted from materials provided by AMETEK Spectro Scientific.

For more information on this source, please visit AMETEK Spectro Scientific.