| The technique of keyhole surgery minimises scarring, speeds healing and reduces the risk of infection. However, it is extremely difficult to carry out delicate surgical procedures accurately in a confined space, such as implanting a bulky device or knotting a suture with the right amount of tension. In the latter case, if a knot is pulled too tight, necrosis of the surrounding tissue can occur, but if it is too loose, the incision won’t heal properly and scar tissue develops. Innovative New Suture Material That situation is about to change, thanks to an innovative ‘shape shifting’ plastic that, according to its developers, Dr Andreas Lendlein and Dr Robert Langer, could be fashioned into novel medical devices such as ‘smart’ surgical sutures that allow an optimised tightening of the knot. This shape memory capability could also allow bulky implants to be placed in the body through small incisions or perform complex mechanical deformations automatically in a confined space. In addition, these polymers are biodegradable, which means they breakdown after a certain time period when inserted into the body, eliminating the need for a second operation to remove the sutures or implant. ‘These applications show significant progress in the medical treatment of human beings,’ says Lendlein, Managing Director of mnemoScience GmbH. ‘The introduction of such medical devices would benefit patients and allow for a dramatic decrease in the overall cost of treatment.’ Shape Memory Materials and Medicine Shape memory materials, which take one form at a certain temperature and transform into another shape when heated, are not new, but until now, no such plastics have been used in medical devices or proved to be biodegradable. ‘To our knowledge, there is no other company producing polymers with such good shape memory properties combined with biodegradability,’ says Lendlein. As early as the 1930s, scientists discovered that certain metallic compounds exhibited the ‘shape memory’ effect when heated above a transition temperature. Since then shape memory alloys (SMAs), such as the nickel-titanium alloy Nitinol, have found uses in actuators and medical devices such as orthodontic wires that self-adjust and stents for keeping blood vessels open. However, despite their broad range of applications, SMAs are expensive, non-degradable, and in many cases lack biocompatibility and compliance, only allowing for a deformation of about 8% for Ni-Ti alloys - this new material allows deformations between permanent and temporary shape of up to 400%. Composition of the Shape Memory Polymer The new ‘smart’ plastic is composed of two components with different thermal characteristics, oligo(ε-caprolactone)diol and crystallisable oligo(ρ-dioxanone)diol, each already used separately in clinical applications such as drug delivery. The biodegradable multiblockcopolymer features two blockbuilding segments, a hard segment and a ‘switching’ segment, which are linked together in linear chains. The higher-temperature shape is the plastic’s ‘permanent’ form, which it assumes after heating. Shape Memory Capabilities The plastic can be stretched or scrunched into temporary forms up to four times larger or smaller than its permanent shape. ‘Independent of their actual temporary shape, these materials can memorise a second, permanent shape,’ says Lendlein. ‘They are automatically transformed into this permanent shape when exposed to a suitable external stimulus, such as an increase in temperature.’ Testing the Shape Memory Polymer To test the feasibility of this concept, the researchers made sutures by heating fibres of their ‘shape shifting’ material to 50°C. They were then stretched to three times their length and cooled to room temperature. These extended fibres were then used to loosely stitch a wound on a rat. When the suture was heated to 41°C (just above body temperature), the thread tightened and closed the wound, applying just the right amount of pressure (0.1 N). Later, after the wound is healed, the material is designed to dissolve and is harmlessly absorbed by the body. |

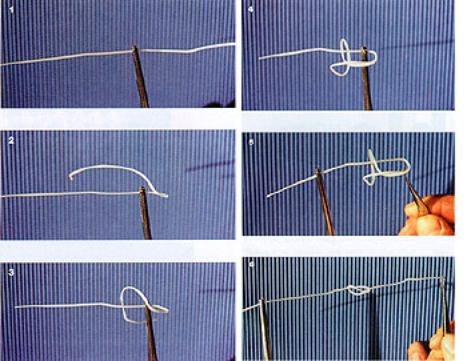

| | Figure 1. This series of images show how the biodegradable shape memory polymer transforms from the temporary shape (1) to its parent shape (6) in 20 seconds when heated to 41°C. | Shape Memory Polymer Stents Only basic research with the material has been completed so far, and more detailed studies are needed before the polymer-with-memory material can be tested in humans. To commercialise the new polymer, Lendlein and Langer have co-founded mnemoScience in Aachen, Germany, which plans to produce scaffolds for engineering new organs and stems. The researchers have already demonstrated the feasibility of this application by getting a long fibre of the material to transform into a corkscrew shape, typical of a stent. Such stems could be compressed and fed through a tiny hole in the body into a blocked artery. The body’s warmth would trigger the polymer’s expansion into its original shape, and over time it would dissolve in the body. Other Uses for Shape Memory Polymers ‘We are working on biodegradable and nondegradable polymers,’ says Lendlein. ‘Our aim is to transfer the results of our research into various products. The biodegradable shape memory polymers are useful in medicine and the non-degradable polymers in other technical applications. According to our future plans, the first product released will be a non-medical one in about two to three years.’ Potential non-medical applications envisaged by Lendlein include carrier systems for cosmetic and beaus care products, optical, electronic an mechanical parts for control systems and recycling concepts, and the repair of accident damage o cars. ‘The body of a car can be restored to it original shape simply by applying heat, such a that produced by a hairdryer,’ he says. The Future for Shape Memory Polymers Whatever applications they are needed for new materials will play a key role in the development of new technologies in the next century. ‘In the field of medical engineering, number of new technologies can only b realised if the biocompatible materials require can be developed,’ believes Lendlein. In this context, this ‘extraordinary invention’ of biocompatible and biodegradable polymers with shape memory properties is just on development in an important group of ‘new materials’ for the 21st century. |