This article helps to gain insights on the development of next-generation advanced ceramics, and to better understand porous structures and sintering processes, improve production, and reduce time to market using microscopy.

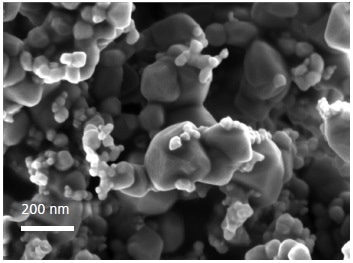

ZnO nanoparticles. Taken using Inlens SE detector, 3 kV on ZEISS GeminiSEM 450.

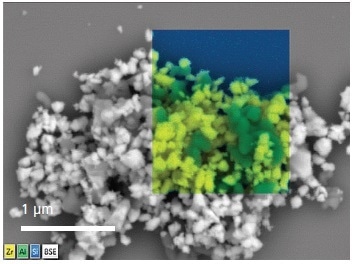

High resolution EDS analysis of ZrO/Al2O3 nanoparticles. Taken using NanoVP, 5 kV, 2 nA, 20 Pa in 10 minutes on ZEISS GeminiSEM 450.

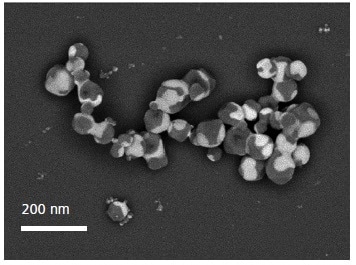

Strong material contrast in oxide nanoparticles. Taken using EsB detector, 2 kV on ZEISS GeminiSEM 450.

Images were taken on unprepared / uncoated samples and no sputter coating was required.

Seamlessly Characterize New Ceramic Materials in a Single Work Flow

A single work flow can be used to optimize ceramics development which can prevent time-consuming sample preparation and thus increase the time for research. ZEISS GeminiSEM 450 provides overall flexibility and ease of use for both analytics and imaging at high resolution.

Perform Chemical Mapping of Synthesized Nanoparticles

By using ZEISS GeminiSEM 450, you can gain confidence in the efficient synthesis processes, chemistry of precursor powders¸ and optimization of the calcination treatment. Live EDS imaging and mapping can be obtained to better view the uniformity in composition across the non-conductive samples, without affecting resolution.

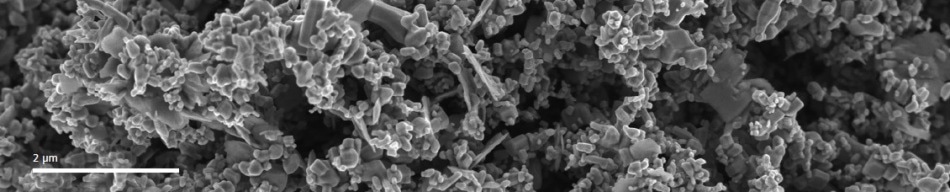

Characterize Ceramic Sintering Processes at Nanoscale

The effect of processing variables during sintering can be better understood by quantifying uniformity to attain the preferred final product. The Inlens EsB detector on ZEISS GeminiSEM 450 helps analyze phase distribution at multiple regions of interest.

Highlights

- Simple imaging of uncoated/unprepared samples

- Easily measure and spatially map the chemistry of ceramic nanoparticles using EDS

- Quickly characterize and map the crystallography of ceramic surfaces

- Combined analytical and characterization techniques in a single instrument

- Simultaneous topographic and compositional information from the advanced material

Ceramics Applications

- Phase crystallization and separation of glass

- Morphology and grain size analysis

- Surface topography and contamination

- Porosity analysis

- Compositional inhomogeneities of ceramic powders

- Correlative microscopy

- Analysis of synthesis of ceramic nanoparticles

- Coating thickness analysis

- Particle mixing

- Inclusions and failure analysis in glass

Technical Data

| . |

. |

| Specimen chamber |

330 mm inner diameter and 270 mm height

Accessory ports: Ten accessory ports on the chamber are provided, three of them for analytic applications with take-off angle of 35º |

| Specimen stage |

5-axes motorized eucentric specimen stage

X = 130 mm; Y = 130 mm

Z = 50 mm

T = -4º to 70º

R = 360º (continuous)

Additional stage options available on request |

| Acceleration voltage |

0.02 – 30 kV |

| Probe current |

3 pA – 40 nA (100 nA or 300 nA configuration are also available) |

| Detectors available in basic configuration |

Inlens Secondary Electron detector

Everhart Thornley Secondary Electron detector

High efficiency VPSE detector (included in variable pressure option) |

| Selected Optional Detectors |

Inlens EsB Detector (Inlens energy selective backscatter)

EDS Detector (energy dispersive spectroscopy)

EBSD Detector (electron backscatter diffraction)

Annular STEM detector (aSTEM4)

NanoVP

Local Charge Compensation

Tandem decal |

This information has been sourced, reviewed and adapted from materials provided by Carl Zeiss Microscopy GmbH.

For more information on this source, please visit Carl Zeiss Microscopy GmbH.