Chocolate is a common, popular food all over the world. It primarily consists of cocoa and sugar, but recipes with dairy products, cocoa butter, nuts, aromas and spices all provide greater product variety and consumer choice. As a luxury food, chocolate is highly subject to cultural preferences and is produced in numerous regional variations with qualities that are influenced by the sensory sensitivity of the tongue.

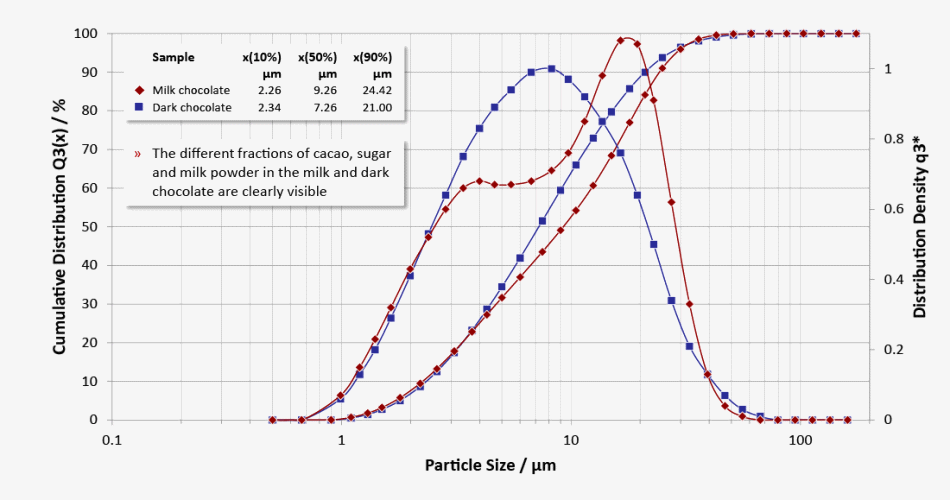

For example, while people in Japan prefer very fine, smooth chocolate with an average particle size of around 10 microns, European consumers tend to prefer chocolate with an average particle size of between 12 and 25 microns. American chocolate, however, sees particle sizes of 30 microns or more.

The Chocolate Manufacturing Process

Industrial-scale production of high quality chocolate is carried out using a technically demanding process. Cocoa beans from a range of tropical regions form the raw material for chocolate production, and these are ground into a viscous mass following cleaning, roasting, sterilizing and peeling. This is known as the ‘cocoa mass’.

The cocoa mass is then pressed, separating out cocoa butter from the dry cocoa mass. Fat is then removed from the dry cocoa mass, and depending on the amount of fat removed, this is then available as a cocoa powder with a residual fat content that is typically between 10 % and 20 % as either an intermediate or final product. This original cocoa mass can be used directly for chocolate bars.

If this cocoa mass is to be processed further to make chocolate, other ingredients must be added. These typically start with sugar being added first then, if required, cocoa butter or other fats plus milk powder, flavors, additives or spices. The chocolate mass is then finely ground and evenly mixed within multi-stage rolling mills. This is done so that ingredients such as sugar crystals, cocoa powder and other solids can reach the required amount of fineness.

The goal within this process is to create a smooth chocolate mixture which contains only a small number of particles that are larger than 30 microns, and no coarser particles that are larger than 70 microns. It is important to note though that particle size not only influences the sensory pleasure of the chocolate, but also the plasticity of the chocolate mass and thus its suitability for additional processing.

At the end of this process, any residual moisture is evaporated before the desired aroma is developed and the smooth character of the final product is created using conching – a mechanical-thermal process.

Proportions of Sugar, Cocoa and Milk Powder Determine Particle Size Distributions for Different Chocolate Types

Milk chocolate (x50 = 9.26 microns) and dark chocolate (x50 = 7.26 microns) have significantly different proportions of fine and coarse particles

Importance of Particle Sizing During Quality Control

The production control used in chocolate manufacture must be able to accommodate the range of particle sizes encountered during the process. These can vary immensely depending on the particular process stage and may range from over 300 microns during pre-rolling to less than 30 microns in the final products.

In order to manage this process on an industrial scale, continuous control of the particle size distribution is required to ensure consistent product quality, both in batch and continuous production, and especially when different stages of the production process take place across multiple sites.

Laser Diffraction in Tempered Suspensions

As well as traditional techniques such as measuring using the micrometer screw or screening, laser diffraction provides an especially useful, reliable and efficient method for ascertaining particle size distribution. The HELOS laser diffraction is ideal for this purpose, and offers demonstrable advantages in the quick, precise and high resolution analysis of chocolate and cocoa masses when used in combination with the temperable wet disperser QUIXEL.

Intuitive and user-friendly application software ensures that measuring routines can be set up quickly and easily. This software also means that it is possible to establish standard measurement methods for automated, user-independent and reproducible results.

HELOS/BR with QUIXEL and LIQIBACK

The QUIXEL measuring circuit includes integrated ultrasound and has a volume of 1 liter, making it ideal for measuring relevant sample quantities for first-class statistical reliability and results that are reproducible, even with more coarse samples. The unit’s tubeless, direct sample management allows for exceptional resistance to all types of organic dispersing media, also allowing for quick thorough and automated cleaning between measurements. Alongside these benefits, dispersing media are also used efficiently and sustainably in combination with the optional reprocessing plant LIQIBACK.

Control of Incoming Dry Bulk Materials

Extending the modular HELOS laser diffraction sensor to include RODOS dry dispersions means that operators can also characterize other ingredients (such as milk powder, sugar, hazelnut pieces, vanilla, fruit pieces or shredded coconut) quickly and reliably.

This information has been sourced, reviewed and adapted from materials provided by Sympatec GmbH.

For more information on this source, please visit Sympatec GmbH.