Interview conducted by Mychealla RiceJul 3 2018

Interview conducted by Mychealla RiceJul 3 2018Orientation Imaging Microscopy (OIM) is a technique based on the automated collection and analysis of Electron Backscatter Diffraction (EBSD) patterns. It is a powerful characterization and analysis tool which enables researchers to better understand and evaluate the microstructure of materials.

In this interview, Matt Nowell, from EDAX talks to AZoM about the new OIM Analysis™ v8, the most powerful, flexible and easy to use tool for visualization and analysis of EBSD mapping data.

How important is OIM Analysis™ for understanding EBSD mapping?

From my perspective, it's very important. Electron backscatter diffraction (EBSD) is a technique comprised of several parts.

You have the microscopy side of it, which is focused on collecting the data, but before that, you must prepare the sample. At this stage, you're setting up acquisition conditions with the aim of getting good data. Once you have that data, you have to ask, “What does this data tell me?” In some cases, the answer is simple, “Do I have a certain grain size?”, “Do I have a certain preferred orientation?”, “Is this sample deformed or not?”.

However, at other times you don't have such an easy solution. If you're trying to research into the unknown and learn about something in more depth then maybe you don't know exactly what you're trying to answer, so in this case, you're investigating your sample - your micro-structure.

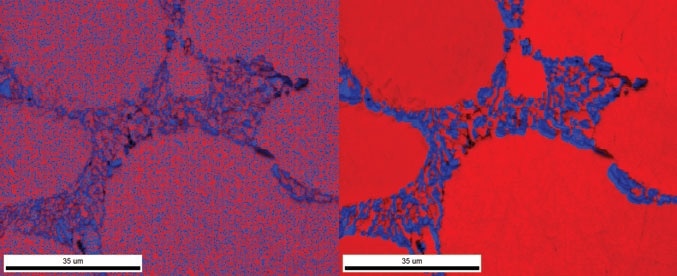

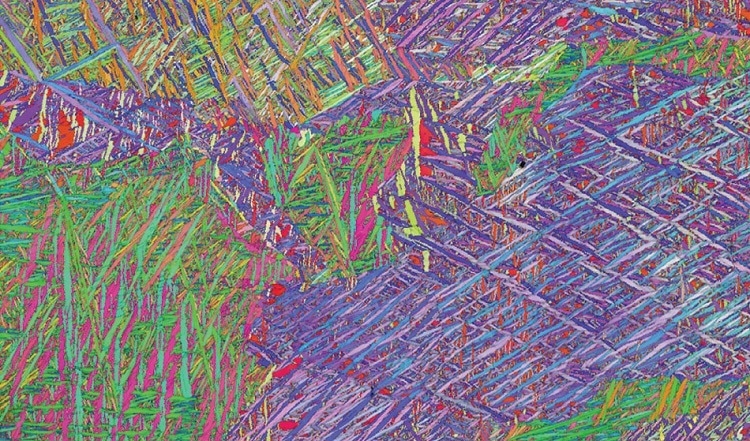

I think that's where OIM Analysis™ becomes very important, because it gives you a very complete toolbox of different outputs that help you visualize microstructure. By that, I mean that it gives you a wide range of different map images: each point in your collection grid is either colored or grayscaled according to some value that's either a direct measure of the orientation or derived from misorientation between two points.

There's a large number of combinations of those maps available, but you're also able to quantify this data, and I use that word as an analogy to EDS or a similar approach trying to evaluate the data numerically. So, for example, you can derive the average grain size, the average grain shape, the percentage of points that have a certain (110) orientation versus a (100) orientation etc.

Between those two techniques, you can provide a complete output of your data, while also having the tools available to investigate it further.

Where does OIM Analysis™ fit into the characterization process?

It fits in after the collection stage of the process. When you're collecting your data on the microscope, you generally get some amount of information - you'll get basic orientation maps, image pattern quality maps, basic phase maps, but that's a pretty static type of output.

Once you’ve collected that data, that's where OIM Analysis™ comes into play. It can be done on the microscope PC, but it's also designed to be used via remote computers - I have it on my laptop and customers get extra licenses to install it in different places in their labs.

OIM Analysis™ is useful when there’s a specific analysis you want to extract from the scans. Sometimes you’re looking for details in one sample, and sometimes you might have ten different scans and want to go through a batch process. At other times you might be sharing a project file with a collaborator.

In all these cases, once you’ve collected the data on the microscope, it then becomes the territory for OIM Analysis™.

Why is collecting data only half of the process for customers?

There are two ways to answer this question. One, it's just the realization that it is only half the process for some people, and we need to get them thinking more about the whole process. I'm obviously a commercial vendor of EBSD systems, and so we sell, present, and demonstrate our products to a wide range of potential users.

Some of those users work along the whole process - they prepare the samples, they analyze the samples on the microscope, then they analyze the results with OIM Analysis™. Sometimes we're having a discussion with the lab manager, and in those cases, once they've got the data off the microscope, from their perspective the process is finished and they hand the data off to a student or to a researcher somewhere. It's out of sight, out of mind at that point.

The other way I'd answer the question is that a lot of work goes into collecting the data. Sample preparation for EBSD can involve a little bit of a learning curve: knowing how to optimize acquisition software in terms of setting up a detector, setting up the band detection, selecting material files, choosing the right step size etc.

It’s a learning curve but people will go through this process and say, "Hey, I collected this data and I have got my basic three or four maps." I think everyone reacts by letting out a deep breath at that point and saying, "Well look, I've done EBSD successfully and I'm happy." However, then they realize that they’re not doing EBSD just to do EBSD – they’re using it to try to solve or learn something more about their material, no matter what that material is.

With that in mind, I think it's that point of realization where people will say “Okay, now that I've done this, I actually have to go and start answering the questions that were my driving force in doing EBSD work in the first place.”

How can OIM Analysis™ help with the second half of the process?

It gives you the tools to interrogate your microstructure in a number of different ways. I mentioned the different types of maps and such – there are around a 100 different possible map types available in the software that all visualize some feature of the microstructure. So, for example, if you're trying to investigate deformation, there's a subset of tools to help you look at that.

My favorite example, because I'm a golfer, is the elastic response of a metal - there's even a map for that. Besides basic visualization, there's a lot of interactivity built into the software, and so if you see a grain that's heavily deformed, it will bend and have a lot of rotation there.

Using the software, you can show how the crystal rotates through a grain, and that gives you an idea of the rotation axis. You can see both how the unit cell changes and how the pattern changes. You can look at and investigate specific grain boundaries to see if they are twin boundaries, or if there is a specific phase transformation relationship between two phases.

With OIM it's not just a static bunch of maps, you're also able to go into a microstructure and interactively interrogate and learn more about it. Once you get to that point, you can start to recognize that in material science we learn a lot about composite materials, and you can start to think of microstructures as composites of different micro-structural components.

The software has a feature that we call partitioning, which essentially allows us to extract subsets of the data for analysis. One of the classic examples is that you can deform something and then recrystallize it, but if it doesn't recrystallize all the way, you see a partially crystallized material.

What you're able to do with OIM is partition your data into the recrystallized fraction versus the deformed non-recrystallized fraction and try to see what's different about those two. Is a different texture developed with the grain size difference? What's the deformation map in the non-recrystallized area? Has the driving force decreased, or has it recrystallized? It's a very comprehensive analysis to make sense of that data.

How is OIM Analysis™ built for different users? Why is that important?

That's a great question and of course there's a wide range of user types and user experience levels using OIM Analysis™. One of the first examples would be a novice user. There are several features built into the software for the novice user. For example, the most common access functions are available on a toolbar called the QuickGen toolbar, so they don't have to dig through lots of options.

This intuitive interface also helps users understand how the outputs are generated, and how the data is organized in a project tree. It gives a lot of visual feedback so that as you start using the system, you start to understand how it works, how to adjust the options etc. As your knowledge of the system grows, you have more and more tools at your fingertips.

Similarly, if you are an infrequent user, you can set up templates, so that once you have the type of analysis you want, you can save them to use again later on. The next time you come back, if you don't remember how you did the original setup, you just click on that template file. You don't have to worry about there being consistency and repeatability of your data analysis approach.

Also, many people wear lots of hats in their jobs, so they need to get out data quickly because they’re juggling lots of tasks. OIM can do that with tools like the templates and our batch processor. The batch processor can handle multiple samples at a single button press and output images in a single operation.

Our more experienced users need the full toolkit. They're able to really go through the feature set to explore it in great detail and get to grips with the amount of information that's present in their microstructures and can be revealed through EBSD.

Can you tell us about the new functionalities that have been introduced to OIM Analysis™ v8? What are the new features and benefits we can expect to see?

The biggest advance that we have included in OIM Analysis™ 8 is the ability to re-index EBSD data. By that, I mean that we can redo the analysis that typically occurs on the SEM. We can take our input from the microscope, and that could be either the position of the diffraction bands that are saved or the saved EBSD patterns themselves. Basically, when we look at an EBSD pattern there are a series of lines or bands that represent the crystallographic planes of the material.

We need to find the position of those bands through image processing. We do that with a ‘Hough transform’. We can save the output of the Hough transform to tell users where the band is located. If the band detection wasn't ideal and we’ve saved patterns, we can go and readjust it. With OIM Analysis™ v8, we're now able to access this data, and then re-index or redetermine the crystal graphic phase and orientation.

That has a lot of important implications in that when we try to collect data online, we're always aiming for near a 100 % indexing success, and understanding why, if we fall below that threshold. Imagine if you've analyzed your structure and you find out that you have these small second phase particles with a different crystal structure, if you're doing this on a microscope, you'd have to go back and re-scan and get that data again. That's not an efficient process.

However now once you've saved the data in OIM Analysis™ you can look at these second phase particles remotely, re-index them, get the correct orientation and put that back together in your data set. You have a more complete description of your microstructure.

This function has a lot of power in that not only can we do this re-indexing, but we can also combine it with the partitioning function that OIM Analysis™ uses to only re-index areas where we have low confidence in our data to begin with.

So, rather than re-indexing a 100 % of our points, if only 10 % of our points are low confidence, we can save the 90 % of points that are good and use our re-processing time only on that 10 % that has a lower confidence index. That allows us to use new tools like our NPAR™ local pattern averaging approach to try to improve data quality in those areas that might need a little bit more help.

Another feature in OIM Analysis™ 8 that we think has a lot of interesting application potential, is a range of new correlative microscopy functionality, EBSD has a unique acquisition geometry. We typically tilt the sample to around 70 degrees, and while we can get simultaneous EDS chemical data, at that position, other complimentary techniques are often difficult to use in the same geometry.

We put in tools that allow us to correlate the EBSD data to other spatially specific measurements and stack those data sets together so that if you want to use the partitioning functions of this with other data - let's say cathodoluminescence data- you could stack those together and then see whether the CL data corresponds with certain grain boundary types - that sort of analysis now becomes much easier.

What applications will benefit from the new functionalities that you have introduced? How?

The easy answer is of course all of them. It's designed as a tool kit without a specific application in mind, but as a resource for all sorts of EBSD users.

In addition, the speed optimization that has been built into the software takes advantage of your modern CPU computer architecture. Pretty much every user can get something out of the new version.

How can OIM Analysis™ v8 enable users to achieve a new insight into microstructural characterization?

The idea behind OIM Analysis™ and EBSD in general is that it provides data that traditionally hasn't been available to material scientists or geologists, and they may not even be aware that it can now be extracted. I like to tell the story that when I was in school I had a crystallography book, and within the first couple of pages it said, “We're glad crystallographers do this, but for the purpose of this book we will assume everything is cubic and isotropic.” What that means is that we’re just going to ignore the effects of preferred orientation or texture on material properties.

When I was learning this, the first level introduction I was given was, “don't think about this” because there aren't easy ways of revealing all this information. X-ray diffraction could give some idea of preferred orientation, but it didn't have spatially- specific information - it was averaged out on a larger macro scale. TEM (Transmission Electron Microscopy) could extract some of the data, but it was focused on just a few grains, and it wasn't particularly automated. You had to go and do a lot of this orientation determination by hand - tilting to specific grain, pull out orientations etc. - and so with EBSD, now you're in between those two. You're getting spatially specific data, and your scale range goes from centimeter scale areas with nanometer-scale type spatial resolution possible.

You're now able to see things that you couldn’t see before. Of course, when you can get that new information it allows you to start to learn more; and lets you refine your ideas, your hypotheses and your materials. You can say, “Here's what's going on in my microstructure” and, for example, if you’re trying to do a certain thing like increase corrosion resistance or improve ductility, you can say, “Hey I can see as I deform this material, I get this type of deformation twin, or instead I see that these grains deform more” - different things like that. Overall, it provides more quantifiable information to users.

What sets this software apart from others on the market?

It is the best tool out there that is designed to focus on the analysis of EBSD data. Often, the focus is on the collection and getting some basic data, but OIM Analysis™ is a commercial product that's positioned so that once you have that data you can really try to make some sense of it. I think that unique approach really sets it apart as a product, as does the whole EDAX perspective on how to approach EBSD.

What do you think OIM Analysis™ v8 means for the future?

We're fortunate at EDAX to have had a long continuous history within the development of EBSD and EBSD mapping, and the OIM Analysis™ software is a platform that's over 20 years old. When you build up a product like that, there's a lot of institutional knowledge that gets embedded into it.

As we build it, revise and improve it, we're learning how our users learn and how they use our systems, and that acts like a feedback loop prompting us to look at how we make this entire process more efficient and effective. We know our users want to acquire good data easily, and that's what we push for. I think OIM Analysis™ acts as the benchmark for what's possible right now with commercial EBSD analysis.

About Matt Nowell

Matt is the EBSD Product Manager at EDAX and has a passion for EBSD and microstructural characterization. Matt joined TexSEM Labs (TSL) upon graduation from the University of Utah in 1995 with a degree in Materials Science and Engineering. At TSL, he was part of the team that pioneered the development and commercialization of EBSD and OIM. After EDAX acquired TSL in 1999, he joined the applications group to help continue to develop EBSD as a technique, and integrate structural information with chemical information collected using EDS.

Within EDAX, Matt has been involved in a number of roles, including product management, business development, customer and technical support, engineering, and applications support and development. Matt has published over 70 papers in a variety of application areas. He greatly enjoys the opportunity to interact with scientists, engineers, and microscopists to help expand the role that EBSD plays in materials characterization. In his spare time, Matt enjoys playing golf and pondering if changing the texture of his clubs will affect his final score.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.